Just clean the floor with soap and water and let it

dry. Plan the tile layout. After measuring, I laid out a row in each

direction to see how I would deal with the ends. I kept a full tile next

to the wall near the walk path which left about a half tile near the wall that

was less visible. If you can, use a full tile near the garage doors as

well. A cut tile at the back of the garage is not a problem and mostly

covered. Use the best contact type glue they recommend.

Follow the instructions.

I put down about a 6 foot X 6 foot area at a time. The walls are edged

with vinyl boarder molding glued on the block wall. At

the garage door an

1/8 inch thick x 1 inch rounded edge molding is glued in place and

finishes it off. The end result has been in place over three years with

excellent results. (Note: the small 1/8 x 1 inch edge molding has

loosened and contact cement was used to put it back. This occurred several

times so I tried Gorilla Glue--it's holding great!!)

the garage door an

1/8 inch thick x 1 inch rounded edge molding is glued in place and

finishes it off. The end result has been in place over three years with

excellent results. (Note: the small 1/8 x 1 inch edge molding has

loosened and contact cement was used to put it back. This occurred several

times so I tried Gorilla Glue--it's holding great!!)

The mechanics crawler rolls nicely over the floor. Its easy to sweep

and clean. For my Corvette and my wife's Crossover purchased 3' x 3' rubber mats

that hold the air-conditioning condensation which usually drips for a while when

we pull in to park. It gets hot and humid in SC!

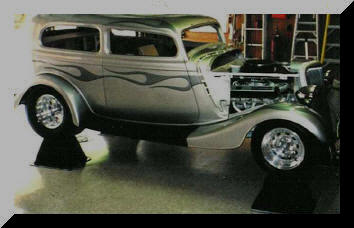

The photo of the car up

on stanchions shows how much nicer it was to work in that environment.

Gibbon made the fiberglass stanchions which keep it up 12 inches. They

are very study, much better than jack stands.