|

CLICK for Partner's Mobile Friendly Website

|

Patented "GAS SAVER SYSTEM" (GSS) cuts waste 85% by reducing starting "GAS BLAST." Typical gas use is cut in half. Just Replace Existing Gas Hose. Over 15,000 in use! Customer List Welding instructor Sue, Holds 25 GSS's for Installation.. Click Pic for Details

HAVE >20 WELDERS? Email: JJerry_Uttrachi@NetWelding.com FOR BULK PRODUCT PRICE; YOU ASSEMBLE ANY LENGTH. Some customers on pipeline supply have ~100 foot lengths. |

|

Description |

Part # WAT- |

Price |

See Photo |

Add Quantity in Cart |

|---|---|---|---|---|

GSS; 3 foot Gas Hose with "B" Threaded Fittings Both Ends Fits Lincoln, most Miller (see below for Miller 211 etc) and ESAB welders. Harbor Freight Vulcan & Titanium welders and regulators also have female Threaded CGA "B"fittings |

Select length Needed

FB3

|

|

A&B below

|

|

| GSS; 4 foot Gas Hose with "B" Threaded Fittings Both Ends HINT: Reversing existing hose will verify if both ends are identical |

FB4 (4 feet long) |

|

A&B below

|

|

FOR MILLER 211 AND HOBART HANDLER WELDERS IF using the supplied regulator/flow control with hose barb outlet.

GSS, FBS4 is a 4 foot Gas Saver System Hose with a male "B" Fitting on Welder End and a Splice Fitting on Regulator End for newer Miller 211 & 141, 215 welders and most Hobart Handlers. The FBS4 cylinder end is for the Regulator/Flowgauge hose barb fitting. (Note: Miller welders with TIG Kits may have both, carefully look at regulator outlets.) Need a longer GSS than an FBS4? CLICK TO SEND AND EMAIL stating what length you want. |

FBS4 (4 feet long) |

|

C below

"Splice Fitting" |

|

GSS; 6 foot Gas Hose with "B" Threaded Fittings installed. |

FB6 |

$90.00 |

A&B below | |

GSS; 12 foot Gas Hose with "B" Threaded Fittings installed. |

FB12 |

$105.00 |

A&B below |

|

GSS; 25 foot Gas Hose with "B" Threaded Fittings installed. |

FB25 (25 feet long) |

$130.00 |

A&B below |

|

|

Don't Have a "B" Fitting On One or Both Hose Ends? |

Order Above Part Numbers |

C below |

Order FBXX |

|

|

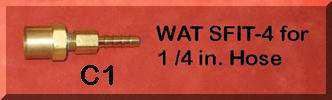

SECOND CHOICE: If You Don't Have "B"

Fittings on Both Hose Ends: Buy an FBx and SFIT-4 Adapter, with a Female CGA "B" to 1/4" Barb for the end needed; often used on robot welders. |

SFIT-4 |

$20.00 |

below |

|

Portable Shielding

Gas Flowmeter Measure Flow Accurately at MIG Gun or TIG Torch in Cubic Feet per Hour, CFH. Reads 5 to 50 CFH, has wide 1 inch ID base opening, fits any MIG Nozzle or TIG Cup. See Details Below.

|

PFM |

$25.00 |

|

|

| Portable Pressure Test Device; Check pressures and demonstrate gas waste | PTD |

$89.00 |

E below |

|

We accept most credit cards and use a secure transaction by PayPal. Select the item then click ADD TO CART BUTTON. You can increase the quantity desired in the SHOPPING CART. NO NEED to join PayPal, just use your credit card for a one time transaction by clicking the "Check Out" Box in the Shopping Cart. Then click the link, "Don't have a PayPal account?" - you'll be directed to enter your credit card information, shipping address etc.

To maintain focus on Saving, Not Selling

shielding gas and to accurately answer customer questions about gas waste

- our patented products are |

||||

|

||||

|

Note: For cost to ship outside the USA, Email Click to Email for Cost to Ship

Gas Saver System (GSS) Info and Photo's of Fittings

If it is desired to lock flows to meet Weld Procedure Specifications, we have another patented product to help, CLICK to See Patented Flow Rate Limiter. Two types of GSS end fittings are available:

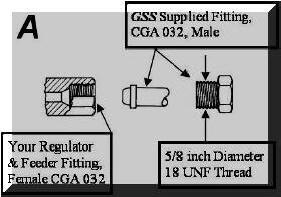

Refer to Photo's A & B above; if both your feeder and regulator have CGA 032 fittings, also referred to as Inert Gas "B"- you can purchase Part Numbers WAT FB3, FB4, FB6, FB12, and FB25 which come in fixed lengths with the fittings installed (Photo B). Easy to check, see if your hose can be swapped end to end. If so you have "B" fittings on both ends! The GSS is then simply threaded into the female fittings on the feeder and regulator or flowmeter. NOTE: "SP" Splice Fittings IF YOU DO NOT HAVE CGA "B" FITTINGS: If either the wire feeder/welder or regulator/flowmeter does not have a female CGA (Compressed Gas Association) Inert Gas 032, "B" fitting, or only a gas hose exits your welder, you can order the desired length, FB3, FB4, FB6, FB12 or FB25 with a splice fitting on either or both ends for the same price (See Photo C Above.) Just send an Email when you place your order and state which end (feeder/welder end or gas supply end) or both require the Splice Fittings installed instead of the CGA "B" fitting. Include your shipping address in the Email so we can match the Email with the order. Note for newer Miller 211 welders and most Hobart Handlers, the welders have CGA female "B" fittings but the supplied regulator/flowgauge has a barb fitting. Our FBS4 comes with the proper fittings. When you receive your hose with the Splice Fittings, simply; 1) cut your existing hose close to the feeder/welder and/or regulator and 2) splice in the GSS hose by inserting the barb fitting into the cut hose. The most common 1/4 inch hose barb will come installed on the GSS you'll receive, if a smaller 3/16 inch barb is needed it is supplied in the package and can easily be installed. The weld and gas savings performance results will be the same with either the "B" or Splice Fittings. Click for more details about installation of Splice Fitting Connections or See Photo C1 Directly Below, about the use of an adapter.

Note, the purchase price includes a paid-up license for the use of our Patent. Optional Adapter if You Don't Have "B" Fittings

|

|||||

|

WAT SFIT-4 splices into a short section of existing hose coming from welder, wire feeder (shown in photo left) or welding robot that does not have a CGA female gas fitting. It may also be used on the gas supply end if the flow control has only a hose barb or other fitting, rather than a female CGA "B" fitting. Once installed you can use our GSS with "B" fittings. The adapter provides the ability to connect and disconnect wire feeders etc simply, with a quality metal to metal CGA gas tight seat, Note we can also provide this fitting for 3/16 inch and 5/16 inch ID hose, Email. Some customers who have inexpensive regulator/flow controls that use a hose barb outlet, plan to upgrade to a quality regulator/flow control that uses a female "B" outlet so order a WAT SFIT-4 fitting. |

|||||

|

Customers asked for a way to measure

actual gas flow at the MIG gun or TIG torch. We added a high quality

portable flowmeter shown on the left. This is What A Customer Said About Our Portable Flowmeter: "Your portable flow meter is better than sliced bread. The welding suppliers in my area looked at me like I had six heads when I described it to them. When I purchased mine off your website, I showed my normal supplier your site and I believe he already has one ordered for himself!" This Email received from a Welding Engineer about what he accomplished with our Portable Flowmeter: "I received the portable flow meter and used it to measure the output on two robotic torches. I was able to show that our processes are not in control. Both torches were supposed to have restriction orifices in line, but had been modified at some point by drilling or removal of the orifices. When tested, they pushed the ball up to the maximum flow position on the meter. We presently have no plumbed-in gas flow meters on any of our production welding torches. Your portable meter won my argument to purchase and install permanent flow meters across the board (total 40). It will also help us to set up our new inline indicators, as well as troubleshoot future porosity problems. An additional benefit, of course, is that we will probably greatly reduce our gas consumption costs. Thanks for a great tool for a great price!" |

|||||

|

This 0 to 100 psi pressure gauge has a CGA 032 "B" female fitting on one end and a male CGA 032 "b" fitting on the other. It can be used to:

1) Check

pressure in the gas delivery hose to define flow restrictions.

2) Check

pipeline pressures. Details on how to use the device are included with the instructions supplied with the product. Order Part Number WAT PTD |

|||||

| Other Products | |||||

|

FLOW RATE LIMITER Set the maximum flow rate you wish to allow. Fits most popular flowmeters SEE DETAILS |

|||||

| You can add products to the Shopping Cart from the following pages: | |||||

|

|

||||

|

|

||||

Remember, The GSS:

|

|||||

|

Free Technical Paper, "MIG SHIELDING GAS CONTROL" CLICK ICON for PDF DOWNLOAD |

|||||

The Miller 211, 141, 215 and Hobart Handlers have a hose barb outlet (pic right) on the flow control so this

The Miller 211, 141, 215 and Hobart Handlers have a hose barb outlet (pic right) on the flow control so this

Payment

Method

Payment

Method Need Another Way to Pay? Click to Email a Request.

Need Another Way to Pay? Click to Email a Request.

Click for Page on "How To Install" and Selection of GSS Fittings and for Special Fittings and Adapters for Robots, Specific Welders etc.

Click for Page on "How To Install" and Selection of GSS Fittings and for Special Fittings and Adapters for Robots, Specific Welders etc.  The patented GSS

consists of a custom manufactured, small ID and large OD gas delivery hose that

replaces the existing hose from your gas supply (cylinder or piped) to wire

feeder (also welder or robot). It includes a special hose fitting with a peak flow restriction orifice on

the wire feeder /welder end to improve weld starts. This peak flow limiting orifice reduces the

initial gas surge flow rate avoiding excess turbulence and the associated air it pulls into the gas shield. The small ID and orifice, reduce the gas waste at weld start by 80 to 85% while leaving enough extra gas to quickly purge air from the weld start area. Note: Gas Flow Rate,

while welding, is set with existing Flowmeter, Regulator/Flowgauge or Orifice at

the gas supply to whatever rate is desired. However if welders are setting excessively high gas flow rates (we have measured 150 CFH at the MIG gun nozzle when flowmeter knobs are opened a half turn from where the flow ball pinned to the top of the tube) then the GSS will limit flow to a minimum turbulent rate of about half of what can be set on a wide open flowmeter! This is more flow than needed for any MIG nozzle size, welding current, gas used or allowable drafts.

The patented GSS

consists of a custom manufactured, small ID and large OD gas delivery hose that

replaces the existing hose from your gas supply (cylinder or piped) to wire

feeder (also welder or robot). It includes a special hose fitting with a peak flow restriction orifice on

the wire feeder /welder end to improve weld starts. This peak flow limiting orifice reduces the

initial gas surge flow rate avoiding excess turbulence and the associated air it pulls into the gas shield. The small ID and orifice, reduce the gas waste at weld start by 80 to 85% while leaving enough extra gas to quickly purge air from the weld start area. Note: Gas Flow Rate,

while welding, is set with existing Flowmeter, Regulator/Flowgauge or Orifice at

the gas supply to whatever rate is desired. However if welders are setting excessively high gas flow rates (we have measured 150 CFH at the MIG gun nozzle when flowmeter knobs are opened a half turn from where the flow ball pinned to the top of the tube) then the GSS will limit flow to a minimum turbulent rate of about half of what can be set on a wide open flowmeter! This is more flow than needed for any MIG nozzle size, welding current, gas used or allowable drafts.

If you

have many MIG welders with different length hoses you may wish to consider

purchasing bulk hose and a pair of the special fittings separately

(Photo

Left).

If you

have many MIG welders with different length hoses you may wish to consider

purchasing bulk hose and a pair of the special fittings separately

(Photo

Left).

Particularly

useful for

industrial fabricators with some Wire Feeders or Welding Robots that do not have CGA

female "B" fittings. Our WAT SFIT-4 adapter may be

the best option. The WAT SFIT-4 has a 1/4 inch hose barb on one end and a female CGA "B" on the other. Note a 3/16 inch and 5/16 inch barb are also available:

Particularly

useful for

industrial fabricators with some Wire Feeders or Welding Robots that do not have CGA

female "B" fittings. Our WAT SFIT-4 adapter may be

the best option. The WAT SFIT-4 has a 1/4 inch hose barb on one end and a female CGA "B" on the other. Note a 3/16 inch and 5/16 inch barb are also available:  Adapter

Installation Details:

Adapter

Installation Details: Order Part Number

WAT PFM.

Order Part Number

WAT PFM.  WAT

PTD

Pressure Test Device

WAT

PTD

Pressure Test Device