| |

|

HISTORY OF SUBMERGED ARC WELDING

continued-- Page 5 (last)

MULTIWIRE-MULTIPOWER APPLICATIONS

No sooner had weld productivity

increased 5 to 10 fold using the Submerged Arc process then even faster welding

systems were developed. |

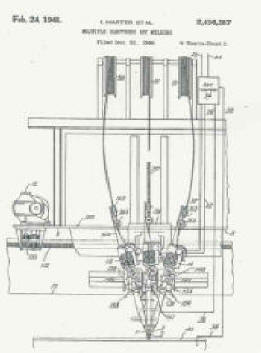

In a patent filed in 1944 by Harter ET Al, number

2,436,387, assigned to Babcock and Wilcox Company a 3

wire system was described. See photo at left of Figure 1 from their patent.

This broad based patent covers the use of various three phase power phasing to

control arc deflection and weld power distribution. A crude analysis of the arc

deflection caused by the interaction of the arcs is presented. They show the

benefits of using different phase angles, 60 versus 120 degrees. The

perspective of using an elongated arc verses just a higher current broader arc

is defined. Frankly it was not until the Multi-Cathode Gas Tungsten-Arc Welding

paper by Anderson and Yenni in 1965 that the reason for this benefit was

described (reference 5).

The Specification appears quite theoretical with no actual weld data or

parameters defined. However the theory of using a lower voltage on the

lead wire then progressively higher voltage on the middle and trial wires is

mentioned. Considering the period when this work was

published it is very advanced.

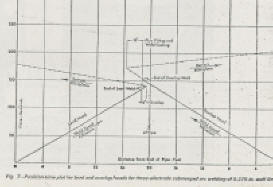

In a June 1952 Welding Journal article written by Clapp and Schreiner

entitled "Characteristics of Submerged Arc Welding with Three Phase Power," (reference 7) welding with three phase AC power is extensively reviewed.

The theory and benefits of various power phasing schemes is defined. They also

operated the system in inert gas to define the arc deflection phenomena

occurring. Plots are provided with various power phasing showing resulting arc

deflection. In addition to the theoretical analysis practical welding

parameters are provided for welding from ¼ inch (6mm) through 2 inch (50mm)

thick plate in two passes. The welding current for the second weld pass on 2

inch (50mm) plate for this two wire AC-AC system was given as 1740 amps lead,

1760 trail. Speed was 17.5 ipm (7.4 mm/s). Considering what the heat input is

for Electroslag welding, this is much lower! |

Don

Knight published a technical paper in the Welding Journal in April of 1954

entitled "Multiple Electrode Welding by the Unionmelt Process" (reference 8). He

reviews parallel wires, two wire AC-AC Scott as well as Series Arc for weld

surfacing. He presents specific applications and photographs of the

applications.

Kubli and Shrubsall presented a technical paper which was

published in The Welding Journal in November 1956 entitled, "Multipower

Submerged-Arc welding of Pressure Vessels and Pipe" (reference 8).They define the

various options for connecting to both DC and AC power. They describe the

benefits of using variable phasing AC to gain a forward deflecting trail arc to

control bead shape and eliminate undercutting. They present welding parameters

and show a number of applications in both pipe and vessel manufacture.

To increase welding speeds in the manufacture of gas and

oil transmission pipe extensive Laboratory work was done at the Linde Division

of UCC

Development Laboratory by among other Len Mauskaff in 1960 and 1961. Laboratory

results with the DC lead AC middle and AC trail system he developed were very

good. The system was installed at the US Steel pipe mill in Provo Utah.

Problems were encountered particularly at the finished end of the pipe,

particularly on the ID weld. Lack of weld penetration and narrowing of the weld

bead were observed. The results were inconsistent. Arc blow was felt to be the

problem with the DC arc causing backward arc deflection as the system came to

the end of the weld. Elaborate changes in the ID grounding were tried but did

not resolve the problems. The trail was terminated. In 1967 when making a

trial of an all AC system the weld data from the previous trial was reviewed

with Lou Warren the Welding Engineer (reference 9). |

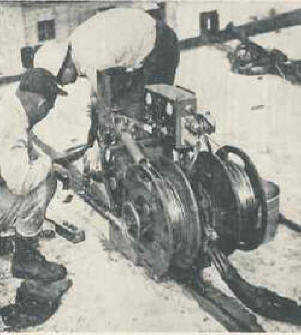

With the

objective of developing a multiwre welding system that would be viable in

production myself (Jerry Uttrachi) and Joe Messina worked for several years at the

Linde Welding Labs

and defined an all AC system that achieved welding speeds higher than the

objective. This work was published in the Welding Journal June 1968

(reference 10). An extensive statistically design experiment yielded

unique power phasing and unexpected welding parameters to achieve excellent

results. The system was installed first at the U. S. Steel Pipe Mill

in Provo Utah.

After extensive mill trials an finding none of the grounding or arc blow

problems previously experienced with the DC-AC-AC system, the mill manager,

Hank Huish, obtained funding to install

all new welding heads, controls and power for 5 ID and 4 OD welders (photo is of

OD welder). The results were so successful the American Bridge Division

of US Steel pipe mill in

Orange Texas also ran a mill trial and installed the three wire system on their

3 continuous OD Berkley cage welders and 4 boom ID welders. This was an

interesting trial since the mill had been equipped with DC-AC. We first

converted the mill to AC-AC Scott then added the third wire. On second and

third shift we shut down our third wire and left a reduced current Scott two

wire AC-AC system. On the 0.388 wall pipe we were welding we were able to

achieve speeds of 75 ipm (32 mm/sec) verses the maximum the mill had been able

to achieve with DC-AC of 60 ipm (25 mm/sec). This proved the benefit of the

forward arc deflection achieved with AC-AC. This three wire system was subsequently

installed in a number of foreign mills, including in Argentina, Italy, Kawasaki in

Japan and the British Steel pipe mill in the UK. Kaiser Engineering in Napa

also designed and built two pipe mills using this system, one for Iran and the

other for PMT in Mexico. They were excellent mills; unfortunately Kaiser did

not see fit to invest in their own mill in California which remained two wire

AC-AC Scott until it was recently closed. Stelco in Canada employed the

system on their new spiral mill designed to produce the Alaska oil and

natural gas pipe lines. The pipe used for what is referred to as the

Alaska Oil Pipeline was made in Japan and the natural gas line was never

built!

|

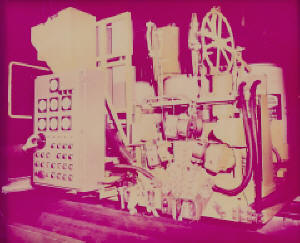

Perhaps

the most creative use of the three wire system was by the A.O. Smith/ Armco pipemill in Houston. They had a unique problem of having three massive

flash butt welders that they wanted to use as fixtures to make OD Submerged

Arc welds. However three OD welds would not meet the production output

requirements.

After extensive laboratory tests (reported in a Welding

Journal article entitled “Hot-Overlap Technique for Three-Electrode Submerged

Arc Welding of Line Pipe” reference 11) they successful obtained API approval

for a unique welding method. This was a very sophisticated

system for its time. Welds were made starting at both ends of the 40 foot pipe

and welding progressed to the center. At the center, one 3 wire welder

stopped and backed up and the other continued to weld through the still molten

flux from the first! All 11 welders (3 OD X 2 plus 5 ID) used our three

wire system. Each welding wire had volt and amp Esterline Angus strip record meters.

The control room with 66 strip recording meters was an impressive site!. Today that can easily be accomplished with a

computer but at the time, paper strip charts were used to troubleshoot potential problems

and assure the hot overlap was working properly.

In 1978 Uttrachi published a review of all of the multiwire

processes including parallel wires, DC-DC, DC-AC, AC-AC and three wire AC

(reference 12). It presents applications for each.

This review of multiwire-multipower history would not be

fair if it did not mention the extensive work done by others such as in Russia

and Japan. Both have published creative work quite prolifically. One paper in my

file is entitled Magneto-Hydrodynamic Phenomena During Twin-Arc Welding by Mandelberg, Sidorenko and

Lopata (reference 13) presents a good theoretical analysis of arc interactions.

I am most proud that one of their 10 references was our “Three Wire Paper;” the

only non Russian reference! An unusual occurrence.

|

|

SIDE BAR

DCCP POWER

A process patent, number 3,659,073, by myself and Messina

filed June, 1970 defines a method of Submerged Arc welding with DCCP power

(constant potential or voltage). Prior to that invention CP power was not used

for slow speed welds made at low current densities. The main reason for introducing it here is the oscillographs presented give some understanding of what is occurring under

the flux! A technical paper was also presented in the Welding Journal

(reference 14).

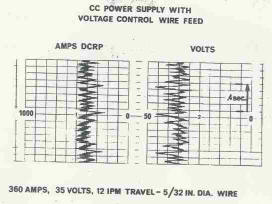

The oscillograph on the left labeled CC Power is a trace of

the amps and volts for a weld made with a 5/32 inch diameter electrode at 360

amps. That is 18,750 amps per square inch where published data at the time

said one could not use CP power below 40,000 amps per square inch. [For

perspective, an 0.045 GMAW weld made at 250 amps is 157,000 amps/square inch.]

Low current densities cause globular drop transfer. Assuming the drop diameter

averages the wire diameter that would yield about 5 drops per second.

These traces validate this calculation with the drop rate probably in the range of 6 to 10 per

second.

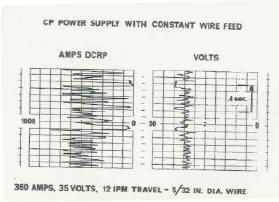

With conventional DCCP power the amperage trace shows large

excursions, ranging from almost 0 to 700-800 amp peak (see figure left).

In this trace, it appears the arc is actually extinguishing about 4 times in one

second. That is about the drop transfer frequency. What is occurring,

is as a molten drop leaves wire, the gap between the slowing feeding wire (30 ipm

wire feed speed) and the plate is larger than the available power supply

voltage! The wire must contact the plate or molten flux to have it reignite.

When it reignites it is probably starting on the hot puddle and leaning the arc

backwards. This creates a peaked undercut weld.

We found that by putting a very large inductor into the circuit, we were able to store enough

energy to deliver it back to the arc as the current tries to go to zero.

This keeps the arc alive and makes the process stable. Welds look like

those made with CC power, flat and uniform. From the traces made with

the system shown at left you'll note there are no arc outages. Note the voltage trace

shows peaks of 45 volts when only 40 open circuit voltage was available.

The extra 5 volts was delivered by the massive inductor.

The advantage of a CP system is in the control.

Maintaining the arc length with CC power requires a voltage control to maintain

the arc length. Prior to microprocessor controls this was not as accurate

or cost effective a means to achieve quality arc performance. To

perform the control function properly, low speed, low inertia motors and

appropriate controls were needed. Starting was also more difficult and

less reliable than achievable with CP power. Today many of these benefits

are less important since arc voltage controls can be made very accurate,

inexpensively.

|

|

TODAY

Today there are a number of 5 and 6 wire systems in use for

various applications. The use of microprocessor based controls makes these

systems viable for use. In addition there are numerous Submerged Arc flux

and wire products that are manufactured in all parts of the world. Weld

performance both physical and mechanical properties can meet the most stringent

needs for steel and some other materials.

|

|

General References:

- The History of Welding by R.D. Simonson, by

Monticello Books, Inc, Morton Grove, Ill, Printed April, 1969.

- “Pullman-Standard Active in Welding Developments”

The Welding Engineer, September 1937.

- “Welding Handbook,” American

Welding Society “1938 Edition

- “Welding in Tanker Construction,” by T. M.

Jackson; The Welding Journal October 1937.

- “Multi-Cathode Gas Tungsten-Arc Welding,”

by J. E. Anderson and D. M. Yenni The Welding Journal April 26, 1965.

- “Characteristics of Submerged Arc Welding with

Three Phase Power”, by E. A. Clapp and N. G. Schreiner; The Welding

Journal, June 1952

- “Multiple Electrode Welding by “Unionmelt”

Process,” by D. E. Knight published a technical paper in the Welding

Journal in April of 1954 entitled

- “Multipower Submerged-Arc Welding of Pressure

Vessels and Pipe,” by R. A. Kubli and H. I. Shrubsall, The welding

Journal, November 1956

- Welding with DC-AC-AC. Private Laboratory data

developed in 1960 and 1961 by Len Mauskaff and private Pipe Mill trial data

viewed at Geneva Steel Provo Utah with Welding Engineer, Louis Warren.

- “Three-Wire Submerged Arc Welding of Line Pipe,”

by Uttrachi and Messina Welding Journal, June 1968.

- “Hot-Overlap Technique for Three-Electrode

Submerged Arc Welding of Line Pipe,” by P.W. Ramsey, T. M. Even and G.

R. Wepfer, Welding Journal, October 1972.

- “Multiple Electrode Systems for Submerged Arc Welding,"

by G. D. Uttrachi, Welding Journal, May 1978.

- “Magneto-Hydrodynamic Phenomena During Twin-Arc

Welding,” by Mandelberg, Sidorenko and Lopata,

Avtomaticheskaya Svarka,

Number 2, 1969.

-

“A New DC Power System for Submerged Arc Welding,” by Gerald Uttrachi,

December 1970.

-

"Health of Arc Welders in Steel Ship

Construction," by US Surgeon General, 200 page review of WWII welders,

1947.

|

|

Page

1

2

3

4 (5

last)

Have a Welder?

Improve Weld Starts and Have Shielding Gas Cylinder Last at Least Twice as

Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half. With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half.

Kyle Bond, President, quickly saw the improvement achieved in weld start

quality as a significant advantage! Kyle, an excellent automotive painter,

was well aware of the effects of gas surge caused by pressure buildup in the

delivery hose when stopped. He has to deal with the visible effects in the

air hose lines on the spray gun in his paint booth! The paint surge is

visible and creates defects unless the gun is triggered off the part being

painted! We can’t do that with our MIG gun!

See Video Showing

What Users Say About Our Gas Saver System-CLICK Here or Picture

Check Out Welding

Math Site |

▲HOME

►CONSULTING

SERVICES

|