| | |

|

HISTORY OF SUBMERGED ARC WELDING

continued-- Page 3

THE PROCESS

IS LICENSED TO FABRICATORS

|

|

Linde did not “just purchase” a proven invention as some

historical reviews state. A great deal of research and development was

conducted by both the Linde Labs

and

Harry Kennedy’s Company. The process was licensed to fabricators charging $0.05

per pound of metal deposited. Kennedy in fact was given a significant portion

of the license fee. I saw a copy of a check which he was sent and for the time

it was a very high dollar amount! and

Harry Kennedy’s Company. The process was licensed to fabricators charging $0.05

per pound of metal deposited. Kennedy in fact was given a significant portion

of the license fee. I saw a copy of a check which he was sent and for the time

it was a very high dollar amount!

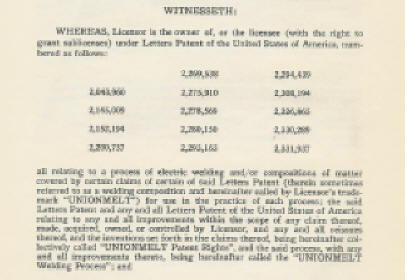

A copy of a part of the end user license agreement is

shown on the left. You’ll note 14 patents are listed. Reviewing a few of them

helps define the effort and timing put forth by both companies. For example,

patent number 2,145,009 was filed in November 1935 by James Keir an engineer

working for Linde. It defines a number of flux backing means.

Patent number 2,152,194 was filed in November of 1935 by L. T. Jones, one of the

original inventors working in Kennedy’s company in California. It

describes magnetic fields applied to the welds to control penetration.

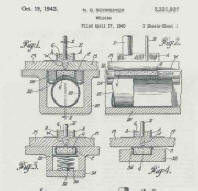

The last mentioned patent

listed is number 2,331,937 which was filed in April 1940 by N. G. Schreiner, an

employee of Linde, photo right. [I spent a great deal of time  working with Norm

Schreiner in the area of the manufacture of gas and oil transmission pipe. Norm

had started with Linde in the mid 30’s during the depression. Even graduate

engineers, like Norm, had a difficult time finding a job. He was involved with Unionmelt from the early days of its development. His knowledge of the process

was excellent and he was always eager to share it with me] This particular

patent related to flux or ceramic weld backing systems. working with Norm

Schreiner in the area of the manufacture of gas and oil transmission pipe. Norm

had started with Linde in the mid 30’s during the depression. Even graduate

engineers, like Norm, had a difficult time finding a job. He was involved with Unionmelt from the early days of its development. His knowledge of the process

was excellent and he was always eager to share it with me] This particular

patent related to flux or ceramic weld backing systems.

In a letter to Linde District Sales Managers in the mid

1940’s there are 900 US fabricators listed as having License agreements to use the Unionment Process. Only about 80 were listed as apparently being inactive. The

list of companies includes all shipyards, vessel shops, pipe manufacturers etc.

In addition to licensing the process domestically, licenses

agreements were listed with a number of companies in Europe, South America,

Scandinavia, India, South Africa, Malaysia, and Japan

|

|

PUBLISHED INFORMATION ABOUT

THE PROCESS

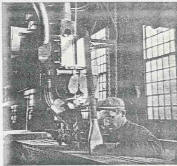

Initially the

Submerged Arc process parameters were not published openly. A few articles

appeared in 1937. One article entitled “Pullman-Standard Active in Welding

Developments,” was published in The Welding Engineer in September

1937 (reference 2). It discusses one application for the use of the process, welding

railroad car center sills. Essentially a butt weld between two rolled Z shaped beams to form

a U with ears. They state; “A powdered flux is distributed ahead of the

electrode wire to expedite the welding and protect it from the atmosphere

gases. No arc is visible. One of the novel features of this machine is a vacuum

cleaner, so to speak, which sucks up the unused welding flux into a container so

it can be used again. The photo at left shows the operator manipulating the

vacuum pick-up. No other details are given. Initially the

Submerged Arc process parameters were not published openly. A few articles

appeared in 1937. One article entitled “Pullman-Standard Active in Welding

Developments,” was published in The Welding Engineer in September

1937 (reference 2). It discusses one application for the use of the process, welding

railroad car center sills. Essentially a butt weld between two rolled Z shaped beams to form

a U with ears. They state; “A powdered flux is distributed ahead of the

electrode wire to expedite the welding and protect it from the atmosphere

gases. No arc is visible. One of the novel features of this machine is a vacuum

cleaner, so to speak, which sucks up the unused welding flux into a container so

it can be used again. The photo at left shows the operator manipulating the

vacuum pick-up. No other details are given.

Another article appeared in 1937. The Welding Journal

published in October 1937 this article entitled Welding in Tanker Construction by

T. M. Jackson from Sun Shipbuilding and Drydock Company in Pennsylvania. It

states’ “Very thorough preliminary investigation indicated that the “Unionmelt”

automatic process adopted for this work would solve the problem of weld

distortion, shrinkage and stress. Actual experience has fully demonstrated

that it does, at least as far as large shop assemblies are concerned. I

mentioned the “Unionmelt process because we adopted it. [Norm Schreiner

worked on the weld sequence for ships] Mechanical properties of the Unionment welds are

also shown.

There

is also a paragraph in the 1938 American Welding Societies “Welding Handbook,”

1938 Edition (reference 3). It simply states at the end of the Chapter 8 on

Automatic Welding, “Another method of producing shielded arc welds

automatically consists of applying powdered flux to the weld. The process

employs welding currents of the order of 1000 to 2000 amperes and makes possible

the welding of plates 1 ½ inches thick and over in a single pass. A bare

electrode is used and powdered flux is used either between dams erected along

the joint or from a hopper around the arc as the weld progresses. The process

of welding produces extremely high welding speeds and welds with physical

properties comparable to those made with the highest quality manual shielded arc

electrodes. The speeds and currents obtainable with the process, which is

patented, are not shown in Table I.” There were a number of other technical papers published

through 1941. Progressively they gave more information about the process and

its benefits. During World War II little information was released. There

is also a paragraph in the 1938 American Welding Societies “Welding Handbook,”

1938 Edition (reference 3). It simply states at the end of the Chapter 8 on

Automatic Welding, “Another method of producing shielded arc welds

automatically consists of applying powdered flux to the weld. The process

employs welding currents of the order of 1000 to 2000 amperes and makes possible

the welding of plates 1 ½ inches thick and over in a single pass. A bare

electrode is used and powdered flux is used either between dams erected along

the joint or from a hopper around the arc as the weld progresses. The process

of welding produces extremely high welding speeds and welds with physical

properties comparable to those made with the highest quality manual shielded arc

electrodes. The speeds and currents obtainable with the process, which is

patented, are not shown in Table I.” There were a number of other technical papers published

through 1941. Progressively they gave more information about the process and

its benefits. During World War II little information was released.

|

|

THE PATENT INFRINGEMENT

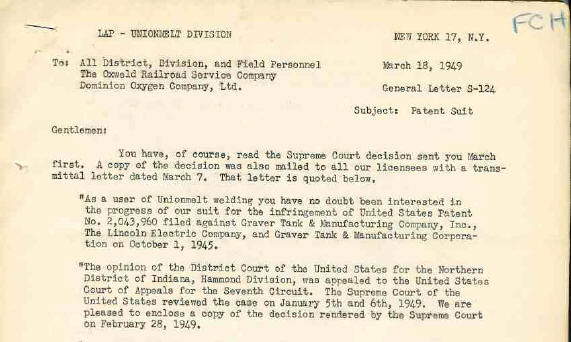

The Lincoln Electric company had marketed their version of

the Submerged Arc process, initially called “Hidden Arc.” They were sued

for patent infringement by the Linde Air Products Company. This famous

patent law case is still studied in law school. The suit was appealed all

the way to the US Supreme Court. The following is from a summary of the

Courts decision delivered by Mr. Justice Jackson in February 1949:

“Linde Air Products Co., owner of the Jones patent for an

electric welding process and fluxes to be used therewith, brought an action for

the infringement against Lincoln and two Graver companies. The trial court

held four flux claims valid and infringed and certain other flux claims and

process claims invalid.”

Lincoln Submerged Arc flux called 660 violated one of the

flux claims held valid. Two letters from the respective sales

departments to customers are of interest. Linde in a letter on March 18,

1949 canceled all License agreements and royalty fees due (the top of that

letter is reproduced below). They increased the price of flux to $0.097

and $0.107 per pound depending on type. A letter of October 1948 had listed the

price of flux as $0.068 and $0.077 for similar fluxes. All prices FOB.

This was an average increase of about $0.03 per pound of flux. Since the

usual consumption of flux is at least 1.5 pounds flux per pound of wire that

would be equal to about $0.045 per pound of weld metal. Almost equal to

the $0.05/pound of weld metal royalty fee they gave up!

|

| In a letter dated March 4, 1949 Lincoln Electric (the top

and bottom of which are reproduced below) informed their customers they were

introducing two new fluxes, 770 and 780 to (presumably) replace the

infringing 660. Of interest, those fluxes were listed as priced at

$0.11 per pound-delivered. |

|

|

An interesting note about J. F. Lincoln’s philosophy on

patents appeared in their company produced magazine,

THE STABILIZER, Winter 1994. It stated; “As a company,

Lincoln did not believe in protection by patents or other forms of monopoly

that interfered with competition. Certain products were patented only

to protect the company from infringement suits."

Since that date the company has changed significantly, including the breath of product line and their view of patents, which they now generate!”

|

|

Side Bar:

OTHER INNOVATORS

Lincoln Electric went on to develop a number of other

fluxes, wires and equipment for the Submerged Arc process including

alloy fluxes and those applicable for hardfacing. They also developed

products and promoted the use of hand-held Submerged Arc systems. Arcos,

McKay and Inco introduced products for welding stainless steel and nickel

alloys. Hobart produced several fluxes, wires and equipment for Submerged

Arc welding. There were a number of foreign innovations by companies such

as ESAB, Oerlikon, OTC, Kobe and others.

Innovations by other persons such as Robert K. Hopkins are

also in the US patent record. Roman F. Arnoldy developed and patented a

number of innovations relating to surfacing with the process through the

addition of iron powder and other alloys. His process, "Bulk Welding," was

a method used to increase weld deposition rate by adding iron powder to the

weld. Bill Gleason of Gleason Engineering developed wires and flux systems

for rebuilding crankshafts of various chemistries including cast iron. A.

F. Manz invented the "Hot Wire" process which allowed increased deposition rate.

There were many others.

This short list of companies and inventors is in no way meant to

be comprehensive.

|

|

Page

1

2

3

4

5(last) 1

2

3

4

5(last)

Have a Welder?

Improve Weld Starts and Have Shielding Gas Cylinder Last at Least Twice as

Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half. With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half.

Kyle Bond, President, quickly saw the improvement achieved in weld start

quality as a significant advantage! Kyle, an excellent automotive painter,

was well aware of the effects of gas surge caused by pressure buildup in the

delivery hose when stopped. He has to deal with the visible effects in the

air hose lines on the spray gun in his paint booth! The paint surge is

visible and creates defects unless the gun is triggered off the part being

painted! We can’t do that with our MIG gun!

See Video Showing

What Users Say About Our Gas Saver System-CLICK Here or Picture

|

|