|

|

|

HISTORY OF SUBMERGED ARC WELDING HISTORY OF SUBMERGED ARC WELDING

continued-- Page 2

JONES, KENNEDY, ROTERMUND PATENT

The key patent that defines the Submerged Arc process is US

Patent number 2,043,960 by Jones, Kennedy and Rothermund. This patent was

assigned to Linde Division of UCC and filed in October 1935. The

Specification states, Page 4, Column 2, Lines 4 through 7 that the application

was in part a continuation of applications Serial Numbers 657,836 and 705,893

filed in February 1933 and January 1934.

There

are no other patents sited against or referenced in US Patent 2,043,960,

indicating this basic process and flux patent did not need to refer to that by

Robinoff. The Specification further discusses what is no doubt the Robinoff

“process” namely on Page 1, Column 2, Lines 23 through 59 parts of which are

quoted: “There is another known means of applying protective flux. It

consists in utilizing thick coating of finely divided material, a flux, which

covers the weld seam. The following is a typical analysis of such a flux…4.34%

Fe2O3…3% Fe. … Moreover the vigor of the arc submerged

under this flux projects a continuous cloud of material into the atmosphere. An

evidence of the amount of gas that is emitted by a flux…welders frequently wear

gas masks…it is not surprising gas holes should be found in the metal of the

weld.” There

are no other patents sited against or referenced in US Patent 2,043,960,

indicating this basic process and flux patent did not need to refer to that by

Robinoff. The Specification further discusses what is no doubt the Robinoff

“process” namely on Page 1, Column 2, Lines 23 through 59 parts of which are

quoted: “There is another known means of applying protective flux. It

consists in utilizing thick coating of finely divided material, a flux, which

covers the weld seam. The following is a typical analysis of such a flux…4.34%

Fe2O3…3% Fe. … Moreover the vigor of the arc submerged

under this flux projects a continuous cloud of material into the atmosphere. An

evidence of the amount of gas that is emitted by a flux…welders frequently wear

gas masks…it is not surprising gas holes should be found in the metal of the

weld.”

Quoting the main uniqueness of the process in the

Specification, Page 2, Column 1, Lines 20 through 37; “We have discovered a

novel process for electric welding wherein the necessary heat is generally by

the passage of a heavy electric current between the metal electrode (usually

bare) and the... objects to be welded…the current being carried across the gap

between the electrode and the objects by and through a conductive melt or

welding composition having appropriate electrical resistive properties. … The

welding composition serves as an active instrumentality, or welding media

inasmuch as it provides heating means, controls the rate of penetration and

quality of welding, purifies the molten metal and protects the molten metal.”

They also define a need for prefusing the flux

ingredients in the Specification, Page 2 Column 1, Lines 42 to 45; “The

chemical reactions between the components of the welding composition must be

completed before it is used in welding. Failure in this regard most surely

invites porosity.”

The patent further defines at least 4 compositions for

fluxes including a preferred method of manufacture.

One questionable fact however is their insistence that the process had no arc. In the Specification they even state a situation which

in their minds proved the point. Quoting Page 4, Column 1, Lines 42 to 53;

“Several circumstances show clearly that our process does not depend on the

formation of an arc of the usual type. If, while the weld is being made, the circuit

is opened externally of the weld and then closed again while the reactive

composition is still molten the current will immediately resume its flow without

any necessarily for moving the electrode into contact with the seam as it would

be necessary to reestablish the arc of the usual type. The heat for melting the

electrode is evidently developed in the conductive melt it self.”

See Side Bar Below

|

|

SIDE BAR:

IS THERE OR IS THERE

NOT AN ARC IN SUBMERGED ARC?

|

The logic defined it the

Kennedy patent as related to there being "no arc" at first appears credible

until we understand just what is happening under the flux. Two

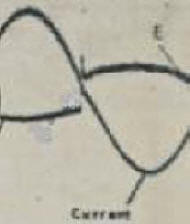

illustrations will show the presence of an arc. Referring to the

figure on the left. The oscilloscope trace on the left shows welding

voltage and current for a single wire AC weld made with Submerged Arc.

Note the sine wave for welding current since this power supply is of a sine

wave design. However note the arc voltage is essentially a

square wave. Also note that the voltage (labeled E) goes almost

instantaneously from a negative value to a positive value. In addition

you can see a voltage spike after the voltage goes positive.

This is a clear graphic

depiction of an arc. What is occurring is the voltage must be, at a

minimum, the sum of the anode and cathode voltage plus whatever resistance

exists across the arc gap itself. The arc does go out as the

current goes through zero. To reignite the arc, the voltage rises

until sufficient ions are produced and the anode and cathode voltages are

exceeded to start the arc again. The curved top of the square wave

exists because the resistive portion of the arc varies in voltage drop as

the current changes. If this were purely resistive melting the

voltage, as is the current, would be a sine wave.

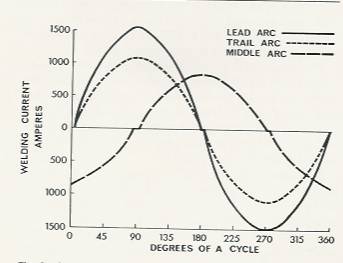

Since it is difficult to see the current holding at

zero for a brief period in that oscilloscope trace, a graphic made of three

wire welding system current traces is shown on the right. You can see

that for each of the three arcs as the current goes though zero it stays at

zero for a short time as the arc is reestablished.

|

|

For modern Submerged Arc parameters

the amount of resistive heating in the molten flux is very low. It is

not an Electroslag process. However one should consider the typical wire

sizes and amperages quoted in the Kennedy patent, namely the smallest wire

being 3/16 inches with a current range of 500 to 800 amps. Also many

welds were made in heavy plate in one pass. The QA test we used for one

high current flux was made with 1/2 inch rod! Welding amperage was 2000

amps AC! The QA test lab had a hole in the ceiling which went into the

room above where a pipe was screwed to the floor to accept the 1/2 inch

diameter rod! For modern Submerged Arc parameters

the amount of resistive heating in the molten flux is very low. It is

not an Electroslag process. However one should consider the typical wire

sizes and amperages quoted in the Kennedy patent, namely the smallest wire

being 3/16 inches with a current range of 500 to 800 amps. Also many

welds were made in heavy plate in one pass. The QA test we used for one

high current flux was made with 1/2 inch rod! Welding amperage was 2000

amps AC! The QA test lab had a hole in the ceiling which went into the

room above where a pipe was screwed to the floor to accept the 1/2 inch

diameter rod! It is possible that at very slow

welding speeds with these low current densities with some of the fluxes

mentioned there could be a significant amount of resistance heating of the

molten flux. Therefore, explaining the postulate defined by Kennedy; the

arc reignites almost instantaneously since the molten flux is easily ionized.

Since the open circuit voltage, for properly designed power supplies, leads

the current by about 90 degrees, sufficient voltage is readily available to

have the arc start almost instantaneously. |

|

Page

1

2

3

4

5(last) 1

2

3

4

5(last)

Have a Welder?

Improve Weld Starts and Have Shielding Gas Cylinder Last at Least Twice as

Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half. With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half.

Kyle Bond, President, quickly saw the improvement achieved in weld start

quality as a significant advantage! Kyle, an excellent automotive painter,

was well aware of the effects of gas surge caused by pressure buildup in the

delivery hose when stopped. He has to deal with the visible effects in the

air hose lines on the spray gun in his paint booth! The paint surge is

visible and creates defects unless the gun is triggered off the part being

painted! We can’t do that with our MIG gun!

See Video Showing

What Users Say About Our Gas Saver System-CLICK Here or Picture |

▲HOME

►CONSULTING

SERVICES

|