|

Don't Need to Spend a Lot of Money to Get a

Much Better Exhaust and Intake for Your S-10 V6

The two

techniques below were used to gain significant flow improvements for minor

cost:

Click to See Exhaust Improvements:

Click to See 1994 Intake Improvements:

Click to See 2002 Intake Improvements:

|

|

MIG Gas Delivery and the Small Block Chevy Evolved in a Similar

Way and Time!

Both had Advances and

Setbacks Before

They Were Optimized!

Click

for a PDF Report on the Similarities |

On both a 1994 and 2002 S-10 had a

local muffler shop install a Flowmaster muffler with two 2/1/2 inch outlets

from the one muffler making dual exhausts. This fellow is an absolute

genius at bending tubing to clear the spare tire etc even on the Stepside.

Since I didn't

change anything upstream of the muffler did I gain a lot of HP? Probably not

but the sound was great! However on the '94 when changing oil I would look at

GM's

"squashed" exhaust crossover pipe coming from the Driver to Passenger side

as it passed under the standard transmission. It was obviously the biggest restriction in the system

(See Photo Above!) Particularly

with hot exhaust gases that occupy more space than when they cool off.

The only reason I could think for GM doing that was the small Ford pick-up

must have had another inch of ground clearance and they wanted to match the

specs!!

When the Flowmaster was being installed

on the 2002 I asked to have the flattened crossover section cut out and

replaced.

Turns out the pipe is only 1.46 inch ID to start with and when flattened the

area reduces to the equivalent of a

pipe only 1.2 inches in inside diameter! You must be kidding - I was installing 2 1/2 inch

duals back stream when all the exhaust exiting the Drivers side was going

through a pipe with only 23% of the area of one 2 1/2 inch exhaust pipe and

hot gas at that! The installer removed the whole crossover and bent a

piece of 1 3/4 inch pipe to the same shape, slipped it on the cut stubs and

welded it in. This way he stayed away from the transmission. Not

quite fully 1 3/4 inch ID the whole way but close. Doesn't sound like

much but compared to the flattened 1.46 inch pipe it's more that twice the

area! Did install high temp insulation between the pipe and the

transmission with two stainless band clamps just in case. The end

result was a pipe about 1/2 inch closer

to the ground so little ground clearance was lost. pipe only 1.2 inches in inside diameter! You must be kidding - I was installing 2 1/2 inch

duals back stream when all the exhaust exiting the Drivers side was going

through a pipe with only 23% of the area of one 2 1/2 inch exhaust pipe and

hot gas at that! The installer removed the whole crossover and bent a

piece of 1 3/4 inch pipe to the same shape, slipped it on the cut stubs and

welded it in. This way he stayed away from the transmission. Not

quite fully 1 3/4 inch ID the whole way but close. Doesn't sound like

much but compared to the flattened 1.46 inch pipe it's more that twice the

area! Did install high temp insulation between the pipe and the

transmission with two stainless band clamps just in case. The end

result was a pipe about 1/2 inch closer

to the ground so little ground clearance was lost.

|

|

'94 S-10 V6 INTAKE

The 1994 intake

used a Helmholtz device to reduce intake noise. It looks like a Bull

Sea Lion Trumpet and the device probably performs in the same way! It

is designed to

provide

a sound wave at particular flows to cancel specific intake air flow waves. provide

a sound wave at particular flows to cancel specific intake air flow waves.

Don't think Intake

Air doesn't make a lot of noise-it does! On the 502/502 Big Block in my

1934 Street rod, even though it has long tube headers with straight through

Bola Mufflers and 3 inch exhaust (SEE LINK)

the intake with the 5 inch X 14 inch K&N makes as much noise than the

exhaust at full throttle!

To

make the system work GM necked down the air intake passage and in the

smallest part it measured 2.27 square inches. To provide more area I

just cut out the bottom of that section and bent some aluminum sheet in a

"U" shape. A few sheet metal screws attached it to the plastic air

cleaner cover and some black paint and black silicon sealed it perfectly.

The intake does takes air from the front of the radiator baffle so its cool.

Used a K&N air cleaner to replace the stock paper filter and now the

narrowest area was 4.47 square inches. Much better than some of the

expensive kits I've seen which put a conical K&N in the hot engine

compartment!

|

|

2002 S-10 V6 INTAKE

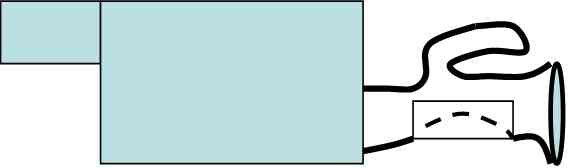

The 2002 S-10 had

a much better arrangement. The intake opening still received air from

ahead of the radiator baffle-a good thing! Perhaps to help provide the

extra power they eliminated the Bull Sea Lion

Trumpet!

The smallest area in the intake was now a reduced section (probably there

again to help with noise) which at its narrowest was 3.14 square inches.

Much better than the '94 but not as large as I was finally able to increase

it. However a quick review of the other restrictions indicated it

wasn't that much smaller. So decided to just "port the passage!"

Now "porting" plastic is no big deal so "just do it." Used a file and

coarse sand paper to clean up first the plastic seem lines which were pretty

heavy. Then worked the narrow area to smooth it out and thin the wall.

The plastic is quite heavy, probably for the case area but no need in the

intake passage. Was able to increase the area to 3.46 square inches by

my calculations and decided that was good enough considering the other

restrictions in the system. Added a K&N filter to replace the original

paper filter. A very inexpensive modification. Trumpet!

The smallest area in the intake was now a reduced section (probably there

again to help with noise) which at its narrowest was 3.14 square inches.

Much better than the '94 but not as large as I was finally able to increase

it. However a quick review of the other restrictions indicated it

wasn't that much smaller. So decided to just "port the passage!"

Now "porting" plastic is no big deal so "just do it." Used a file and

coarse sand paper to clean up first the plastic seem lines which were pretty

heavy. Then worked the narrow area to smooth it out and thin the wall.

The plastic is quite heavy, probably for the case area but no need in the

intake passage. Was able to increase the area to 3.46 square inches by

my calculations and decided that was good enough considering the other

restrictions in the system. Added a K&N filter to replace the original

paper filter. A very inexpensive modification. |

|

Engineering a 1934 Pro Street Rod

!

Click

for a 67 Page PDF

Click for YouTube Video

Overview of Car

Click for YouTube Video

Overview of Car |

|

Modifying an 850

Holley for a ZZ 502 Chevy Big Block

|

|

|

ONE PAGE GAS SAVER SYSTEM

SUMMARY |

|

|

Cooling a Chevy ZZ 502 Big Block in a Street Rod |

|

|

Adding 250 HP Nitrous to a ZZ 502 Big Block |

|

|

MIG

Gas Saver System

$aves money

!

|

|

|

3 Inch Stainless

Exhaust System |

|

|

"Building the Body" |

|

|

"Construction Details Index |

|

|

"Building Dash Extension"

|

|

|

"Building Stereo Wall" |

|

|

"Building Transmission Tunnel" |

|

|

"Fabricating the Interior" |

|

|

"Other Fabricated Parts"

|

|

|

"Other Features" |

|

|

Corvette Accessory Installation Info

|

|

| "WARNING:

"Weld

Safely" |

|

|

►Purchase Gas Saver System

PRODUCTS |

|