|

HISTORY OF MIG (GMAW) WELDING

Numerous

articles credit the invention of MIG welding to a number of sources. Some

references mention the invention occurring in the 1920’s which, appears to be at

least partially true. This overview will focus on process innovations and

not specific equipment or filler metals developments for which there are also

numerous significant inventions.

Jerry Uttrachi, President WA Technology

SOURCES OF INFORMATION

A search of the US patents and some AWS Welding

Journal articles helped define the sequence of events that advanced the

science of

GMAW (also referred to as MIG for Metal Inert Gas or MAG for Metal Active Gas

welding since for welding steel some reactive gas is needed such as a small

amount of oxygen or 8 to 25% CO2 ). My

preference is to use MIG welding as that is the more common terminology used in

North America and is easier to pronounce than GMAW! Getting hung-up with

the technical issue of using MIG when welding aluminum with pure Argon or MAG

when welding steel is also something not used in the Americas. MIG, in my

opinion, is far better than getting tongue tied with GMAW and using terms like

"Wire Welding" which is unfortunately all to common. I also lived

some of the history of MIG developments knowing and working with some of the

folks directly involved with the

process development. Documentation of the facts presented is given with patent

numbers, references and photographs. It is suggested students search the US

Patent Record using the patent numbers provided. It is available for

patents issued from 1790 free of charge on the Internet. Often other

patents than those mentioned can be obtained by looking at those sited in

subsequent patents. On the last MIG History page the specific references sited

are listed as well as some other significant historic references which should be

considered since the research work in that era was very comprehensive. The

use of other than US sources was limited, however if foreign patents were

granted in the US or technical papers were published in the AWS Welding Journal,

a number were reviewed.

ALL PUBLICATION RIGHTS AND MATERIAL PRESENTED ARE THE SOLE

PROPERTY OF WA TECHNOLOGY, LLC, AND SHOULD NOT BE COPIED WITHOUT WRITTEN

PERMISSION.

ANYONE IS FREE TO MAKE ONE COPY FOR PERSONAL

USE. THIS CAN INCLUDE ONE PHOTOCOPY, ONE PRINTED COPY, AND ONE EMAIL COPY. THIS

INCLUDES USE BY A STUDENT FOR AN ACADEMIC PURPOSE.

THE EARLY

DAYS

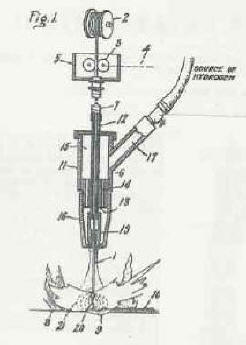

As

some references mention, the idea for MIG welding can be traced to some early

research. For example, a patent by Alexander, filed in December 1924

(Patent Number 1,746,207) appears to present a MIG welding system much as used

today. See attached figure from the patent on left) However they state

having tried unsuccessfully to

use carbon dioxide as a gas shield. On Page 1, Lines 91 through 96 of the Patent

Specification Alexander states; “I have also welded in an atmosphere of

carbon-dioxide and in an atmosphere of illuminating gas and in every case the

welds were brittle and not as good as welds made in air.” Perhaps the power

source used did not have the proper characteristics although it was apparently

one frequently used for welding with

solid wires in air. His patent is for welding with Hydrogen, often referenced

as the hydrogen welding process. The hydrogen ignites with the surrounding air

and surrounds the arc with a reducing atmosphere. The arc however is

acknowledged as proving most of the welding heat. As

some references mention, the idea for MIG welding can be traced to some early

research. For example, a patent by Alexander, filed in December 1924

(Patent Number 1,746,207) appears to present a MIG welding system much as used

today. See attached figure from the patent on left) However they state

having tried unsuccessfully to

use carbon dioxide as a gas shield. On Page 1, Lines 91 through 96 of the Patent

Specification Alexander states; “I have also welded in an atmosphere of

carbon-dioxide and in an atmosphere of illuminating gas and in every case the

welds were brittle and not as good as welds made in air.” Perhaps the power

source used did not have the proper characteristics although it was apparently

one frequently used for welding with

solid wires in air. His patent is for welding with Hydrogen, often referenced

as the hydrogen welding process. The hydrogen ignites with the surrounding air

and surrounds the arc with a reducing atmosphere. The arc however is

acknowledged as proving most of the welding heat.

|

|

If you look closely at his welding torch you’ll see the

hydrogen is introduced in a very small nozzle. Could it be the high

velocity flow used and the small nozzle was he used to test these other gases? He was

then certainly aspirating air into the shielding stream which would cause an

unstable arc and brittle welds! In excess of 6% nitrogen in the shielding

gas surrounding the arc and weld porosity will

occur (See Reference).

Even with modern MIG welding systems, excess shielding gas velocity caused by

too small a shielding gas nozzle or too high a flow rate produces air

aspiration and weld quality problems.

(See Reference.)

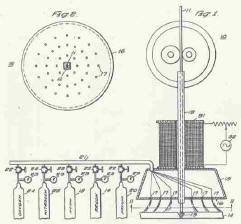

A patent filed by Brace in September 1936, assigned to

General Electric (Patent Number 2,053,417) shows what could be said to be the MIG welding

process. He defines the use of a number of shielding gases (see his figure 1

right.) However his shielding device is shaped like a shower head.

Of interest, Gorman in the original TIG Gas

Lens Patents discusses how his research using porous diffuses worked like a

shower head and pulled air into the area between the steams!

[Note: air flow is

not intuitive which is why NASCAR, Indy Car and Formula 1 race teams spend

tens of millions of dollars each year on wind tunnel testing. It's like folks who

drive with their Pick-up Truck Tail Gates Down

thinking they are improving gas mileage when it actually makes it worse!] Also

the gas mixtures defined by Brace, although broad, may not have been appropriate for good

arc stability. One can tell the metal transfer was not very good

by the electric coil shown surrounding the wire (numbered 31) in the figure.

Brace states on Page 2 of the

Specification, Lines 47 to 53; “I have found that the magnetic flux produced by

the winding 31 when energized with an alternating-current source sufficiently

disrupts the surface tension which would otherwise be present to cause the

formation of relatively large globules of the molten metal from the welding

electrode 11.” Obviously a complex way to achieve what would be simply

controlled with the proper power supply characteristics and shielding gas

mixtures! A patent filed by Brace in September 1936, assigned to

General Electric (Patent Number 2,053,417) shows what could be said to be the MIG welding

process. He defines the use of a number of shielding gases (see his figure 1

right.) However his shielding device is shaped like a shower head.

Of interest, Gorman in the original TIG Gas

Lens Patents discusses how his research using porous diffuses worked like a

shower head and pulled air into the area between the steams!

[Note: air flow is

not intuitive which is why NASCAR, Indy Car and Formula 1 race teams spend

tens of millions of dollars each year on wind tunnel testing. It's like folks who

drive with their Pick-up Truck Tail Gates Down

thinking they are improving gas mileage when it actually makes it worse!] Also

the gas mixtures defined by Brace, although broad, may not have been appropriate for good

arc stability. One can tell the metal transfer was not very good

by the electric coil shown surrounding the wire (numbered 31) in the figure.

Brace states on Page 2 of the

Specification, Lines 47 to 53; “I have found that the magnetic flux produced by

the winding 31 when energized with an alternating-current source sufficiently

disrupts the surface tension which would otherwise be present to cause the

formation of relatively large globules of the molten metal from the welding

electrode 11.” Obviously a complex way to achieve what would be simply

controlled with the proper power supply characteristics and shielding gas

mixtures!

|

|

FIRST

PRACTICAL MIG SYSTEM

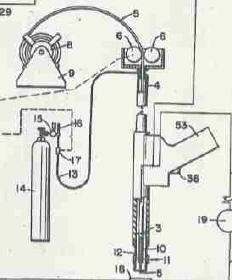

Many

acknowledge the first practical MIG system was defined in Patent Number

2,504,868 filed by Al Muller, Glen Gibson and Nelson Anderson in January of 1949, assigned to Airco. Their 16 page Specification is excellent and describes

fully how the process works. Some of their claims are very interesting: Many

acknowledge the first practical MIG system was defined in Patent Number

2,504,868 filed by Al Muller, Glen Gibson and Nelson Anderson in January of 1949, assigned to Airco. Their 16 page Specification is excellent and describes

fully how the process works. Some of their claims are very interesting:

-

In Claims 8, 9, 11 and 12 they refer the shielding gas

being, “non-turbulent to exclude air from the arc.”

(Perhaps we have forgotten

this early knowledge when excess shielding gas flow rates are set or high gas

surge at the weld start is accepted! See Reference). In Claim 10 they define the shielding gas as being

helium or argon and mixtures of carbon monoxide and carbon dioxide. (Although

carbon monoxide may work, for safety reasons it should NOT be used!)

-

In Claim 8 they define the

metal transfer means as being, “a spray of fine discrete droplets within the

gas shield.” This was the transfer mode employed until the next major

breakthrough, short circuiting MIG, or “Short Arc” as it’s often called.

(Note, although there are some others occasionally credited with

"inventing" MIG welding, a check of the prior patents sited in the "Gibson et

al" patent

assigned to Airco, # 2,504,868, such as the Harry Kennedy patent assigned to the Linde Air

Products Company, show it and the others referred to equipment items for

submerged arc welding or an oxy-electric cutting torch -NOT gas shielded MIG

welding. The US Government grants patents for an inventor to

teach others the science. That is why they are given a 20 year

monopoly! Read the teaching, since this is mostly provided in simple

English. The claims are written differently (in patent lawyer

legalese!) and may be more difficult

to understand but the Specification should be clear.)

|

Page

1

2 3

(4 last) 1

2 3

(4 last) |

Stop

Wasting Shielding Gas!! Stop

Wasting Shielding Gas!!

See YouTube Videos

Including Our Patented MIG Shielding

"Gas

Saver System" (GSS)

Science of MIG

Shielding Gas Flow Control

Why MIG Gas Waste

Detailed Review of GSS

Short Overview of GSS-90 Seconds

What User Say About

GSS

Welding Race Cars

Rat Rods-Then and Now

Welding: Go Green

Lincoln Busiensss Philosophy NEW REVISED 2019 with 2014 Book by Lincoln President Don Hastings

|

▲HOME

►Purchase Gas

Saver System

|