|

|

|

HISTORY OF MIG (GMAW) WELDING

continued-- Page 4

RECENT PROCESS ADVANCES

|

Several companies

have used modern microprocessors to analyze arc characteristics and develop

systems that make better starts, weld over gaps, allow CO2 to have reduced

spatter (particularly an issue in Japan and other countries where Argon prices

are much higher than in North America) and to make other MIG process advances.

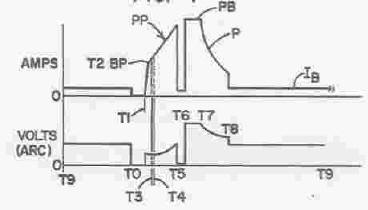

One of the more recent and well documented in the patent record is the Lincoln STTTM . Patent Number 5,001,326 by Stava

assigned to Lincoln was filed in February 1990. Other prior patents

are also sited. It describes a control system that allows control of weld

heat and the ability to achieve low spatter levels with CO2 shielding gas.

See above waveform from a figure in this patent. |

|

The

use of microprocessors allowed ESAB to recently introduce a MIG welder

called QSET.TM

A difficult

training task is instructing someone to set up Short Circuiting GMAW

(MIG "Short Arc.") ESAB introduced this product that

automatically sets the correct welding parameters for a given wire/gas

combination. The

use of microprocessors allowed ESAB to recently introduce a MIG welder

called QSET.TM

A difficult

training task is instructing someone to set up Short Circuiting GMAW

(MIG "Short Arc.") ESAB introduced this product that

automatically sets the correct welding parameters for a given wire/gas

combination.

The welding operator selects the wire feed

speed and welding machine sets the proper "short arc conditions. There

are no synergic lines, just a single knob to set the wire feed speed and

obtain the optimum welding parameters. The welder can still elect to modify

arc length by means of a voltage trim control. A further benefit of

system is that the control algorithms maintain a constant power in the arc

and depth of penetration, even if the contact tip distance changes. Because

the arc stability is closely controlled, there is also less weld spatter

and, therefore, less post-weld cleaning.

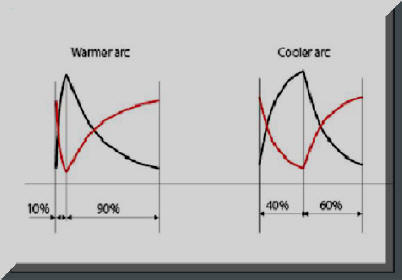

ESAB

explains that in a stable "Short Arc" process the ratio of short circuit and

arc time lies in a narrow range. The QSET welder continually measures

and controls the short circuit pattern. A test weld is made and in a

few seconds the welding machine optimizes and maintains the optimum

conditions. Maintaining the proper "Short Arc" conditions is important

to avoid cold welds or "cold lap" as it is often referred. ESAB

explains that in a stable "Short Arc" process the ratio of short circuit and

arc time lies in a narrow range. The QSET welder continually measures

and controls the short circuit pattern. A test weld is made and in a

few seconds the welding machine optimizes and maintains the optimum

conditions. Maintaining the proper "Short Arc" conditions is important

to avoid cold welds or "cold lap" as it is often referred. |

|

Another

recent advance if the use of Tandem MIG. Although versions of this process

were patented as early as 1957, little was done with the process until recently.

Modern controls and power allow process variations that make these processes

viable. Another

recent advance if the use of Tandem MIG. Although versions of this process

were patented as early as 1957, little was done with the process until recently.

Modern controls and power allow process variations that make these processes

viable.

The use of multiple Tandem MIG systems for making circumferential welds in

line pipe is very productive.

|

| Shielding

Gas Delivery Optimized

The early developers of MIG welding understood what was needed to properly

deliver shielding gas such as the need for pressures on the inlet side of

the gas solenoid

being above

25 psi. This was needed to have the gas flow remain at the

preset level when spatter built-up in the torch nozzle and the torch cable

bent and twisted in operation. However this created excess shielding

gas stored in the delivery hose when welding stopped that was mostly wasted

at the weld start. being above

25 psi. This was needed to have the gas flow remain at the

preset level when spatter built-up in the torch nozzle and the torch cable

bent and twisted in operation. However this created excess shielding

gas stored in the delivery hose when welding stopped that was mostly wasted

at the weld start.

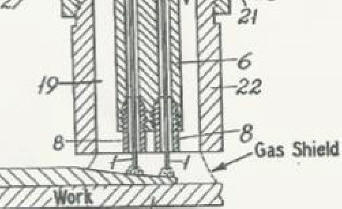

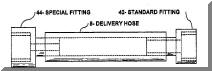

Stauffer in 1982 patented a

device ( patent figure left, Patent Number 4,341,237) to reduce this start

surge. He also understood that some extra gas was needed at the

start to quickly purge the torch nozzle weld start area or air. He

built an accumulator into his system that delivered the proper amount of

extra start gas. However his device used low pressure eliminating the

automatic flow compensating feature and since the pressure was low the

accumulator and therefore the device was quite large and comp lex. lex.

A much similar and effective

system (patent figure right) was developed that optimized the gas flow at

the weld start. It also eliminates the excess stored gas

significantly reducing gas waste. It still delivers a sufficient

amount of gas at the weld start, at a flow rate that avoids excess

turbulence, to purge air from the MIG gun nozzle and weld start area. It was patented by Uttrachi in 2003,

Patent Number 6,610,957 (Hey that's me!) Uttrachi

had additional patents for other devices to reduce gas waste and improve

weld start quality issued in 2006, Patent Numbers 7,015,412 and 7,019,248.

|

|

There are many innovations we have no doubt missed.

However by referencing the patents mentioned one can find substantially more

patents and references that may be of interest. Patents have the objective

of teaching the reasons why something works. A patent as a bargain between

the Government and the inventor. The Government offers a short-term monopoly in

return for a full description of the invention, which is published

by the Patent Office. This exchange of a monopoly for a full description

underpins the patent system and leads to published patent documents

being the most comprehensive source of technical information in the world, for

practically every area of technology. That is why one obtains a limited

time monopoly so

the information is fully disclosed for posterity. Some inventors do a

better job than others of fully disclosing their insight into the product or

process details. |

|

REFERENCES

The references below give the student of MIG some base to search

further so as not to have to reinvent the wheel, or worse conduct future

research without knowing it was already invented!

-

"Controlling the Melting Rate and Metal Transfer in

Gas-Shielded Metal-Arc Welding. Part II," by Al Lesnewich, Welding

Journal 1958, 37(9), pp 418-s

-

"GMAW-A Versatile Process on the Move," by Kevin

Lytte, Welding Journal, March 1983, pp15.

Some Other References Not Sited But

Significant

-

"Controlling the Melting Rate and Metal Transfer in

Gas-Shielded Metal-Arc Welding. Part I," by Al Lesnewich, Welding

Journal 1958, 37(8), pp 343-s

-

"Characteristics of Inert Gas Shielded Metal Arcs,"

by Muller, Greene, and Rothschild, Welding Journal August 1952, pp 717-s

- “Energy Distribution in

Electric Welding,” by C. E. Jackson and A. E. Shrubsall, Welding Journal, 29 (10) Research Supplement 520-a

to 521a (1959).

- “Control of Penetration

and Melting Ratio with Welding Technique,” by C. E. Jackson and A. E. Shrubsall, The Welding Journal, 32

(4) Research Supplement 172-s to 178-s (1953).

-

"The Effect of I2RHeating on Electrode

Melting Rate," by Wilson, Claussen and Jackson, Welding Journal, 1956,

35(1), pp 1-s

-

"The Inert Gas Shielded Metal Arc Welding Process"

by Wooding, Welding Journal, 1953, 32(4,5); pp299-s, 407-s

-

"The Aicromatic Welding Process'"

by Muller.

Gibson, and Roper, Welding journal, 1950 29(6), pp 459-s

-

"Inert Gas Shielded Welding Arc Behavior and Metal

Transfer Characteristics" by George Skinner and Yenni, Electric Arc

and Resistance Welding, IV July 1954, American Institute of Electrical

Engineers, Publication S-64, pp 16-27

-

"Arc and Bead Characteristics of the Aluminum Self

Adjusting Arc," by Needham and Smith, 1958 British Welding Journal, 5,

pp 66-76

-

"Carbon-Dioxide Shielded Consumable Electrode Arc

Welding" by Rothschild, Welding Journal 1956, 35(1) pp 19-29

-

"GMAW Shielding Gas Flow

Control Systems" by G. D. Uttrachi,

Welding Journal 2007, 86 (4) pp 22-23

|

| Page 1

2

3

(4 last)

Have a Welder?

Improve Weld Starts and Have Shielding Gas Cylinder Last at Least Twice as

Long!

Note: Our Patented

GSS

is Not Available in "Stores"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System ( GSSTM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half. With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air to be sucked into the

gas stream causing poor weld starts. With the

GSS replacing their existing hose, the peak flow surge at the

weld start was about 50 CFH. Total gas use was cut in half.

Kyle Bond, President, quickly saw the improvement achieved in weld start

quality as a significant advantage! Kyle, an excellent automotive painter,

was well aware of the effects of gas surge caused by pressure buildup in the

delivery hose when stopped. He has to deal with the visible effects in the

air hose lines on the spray gun in his paint booth! The paint surge is

visible and creates defects unless the gun is triggered off the part being

painted! We can’t do that with our MIG gun!

GAS SAVER SYSTEM (GSS TM)

PURCHASE INFORMATION

Check Out Welding

Math Site

|

|

"WARNING:

"Weld

Safely" |

|

►CONSULTING

SERVICES

|