| Production

Results:

Download

PDF of Several

GSS Testimonials

Click Following Links To Go To Applications of

GSS:

-

Case 1 - -

Truck Body Builder Gets 50% Gas Savings

-

Case 2 - - Improvement in Start Quality with 33%+ Gas Savings

-

Case 3 - - Small and Home Shops Can Also Benefit from GSS

- Case 4 - - 112

GSS's Installed - Saved Over 30%

-

Case 5 - - Aluminum Fabricator Saves 40%; Installs 93

System

- Case

6 - - Bar Joist Mfg. Improves Starts/Saves Gas

- Case 7 - - Truck Storage Box Mfg. Achieves 63% Gas Savings

- Case 8 - - Pipe Fabricator Saves 41% in Shielding Gas

- Case 9 - - Major Trailer

Manufacturer Saves 25% in Production

- Case 10

- 6 Foot Delivery Hose Yields 40+ % Gas Savings

- Case 11 - 350 Gas Saver

Systems Purchased by Military Sub Supplier

- Case 12 - Texas

Hydraulics Saves 35% with Flow Rate Limiters

- Case 13 - Fabricator in

Mexico Saves 30 to 42% Shielding Gas

- Case 14 - Irrigation

Pipe Mfg. Saves 40%, Installs 120 Systems

- Case 15 - Bucyrus China Orders Gas Saver Systems

- Case 16 - Waste Disposal

Mfg Saves 44%, Installs 270 GSS Systems

|

|

Production Example Case 1

Truck Body Builder Gets 50% Savings

With

GSS

Double

A Body Builders in Pamplico, SC started producing custom truck bodies 40 years

ago. They now consume about 40,000 lbs of steel per week. Most of

the steel arrives flat and is cut, bent and welded into about 120 truck bodies

each month. Double

A Body Builders in Pamplico, SC started producing custom truck bodies 40 years

ago. They now consume about 40,000 lbs of steel per week. Most of

the steel arrives flat and is cut, bent and welded into about 120 truck bodies

each month.

MIG welding

is employed almost exclusively for fabrication. They use 0.035 inch

diameter solid wire which allows welding in all positions. All 23 MIG

welding machines use an Argon/CO2

shielding gas mixture to keep spatter to a minimum and produce high

quality, visually attractive welds. The shielding gas is piped throughout

much of the shop. Most of the wire feeders are located 30 to 40 feet from

the gas supply pipeline.

One off the owners, Ken Ard knew they

were using more shielding gas then needed. Ken heard about the

benefits of a recently invented product developed to solve the waste

problem. He set up a test on two welding machines that had their shielding gas supplied with cylinders. The test started with

full gas cylinders on both welders. One welder incorporated the

GSS and the other used the standard ¼

inch diameter shielding gas delivery hose.

Ken had read about the benefits of the

GSS system and was pleased but not surprised

that

he achieved about twice the amount of welds with the

cylinder of gas on the system with the

GSS

installed.

Shielding gas is a significant cost in the operation and the savings

achieved will assist in keeping Double A Body Builders competitive.

After a year in production Ken Ard is very pleased with the cost savings

results. He has expanded with 20 more welders, each with

GSS.

had their shielding gas supplied with cylinders. The test started with

full gas cylinders on both welders. One welder incorporated the

GSS and the other used the standard ¼

inch diameter shielding gas delivery hose.

Ken had read about the benefits of the

GSS system and was pleased but not surprised

that

he achieved about twice the amount of welds with the

cylinder of gas on the system with the

GSS

installed.

Shielding gas is a significant cost in the operation and the savings

achieved will assist in keeping Double A Body Builders competitive.

After a year in production Ken Ard is very pleased with the cost savings

results. He has expanded with 20 more welders, each with

GSS.

Go

To published Article Entitled: " A Solution for Welding Shielding Gas Waste." Go

To published Article Entitled: " A Solution for Welding Shielding Gas Waste."

It includes more details of Double A Body

Builders test.

|

| PS:

We have had a number of

trailer/truck body manufacturers purchase systems. After testing 3 systems

one called to purchase 15 more indicating 85% more welds made with the Gas Saver

System. They essentially duplicated the Double A Body Builders test

results and reported getting better starts. Interesting, this company located in Utah purchased an additional

8 to 10 systems at a time and the gas savings achieved paid for the next order!

They purchased a total of 38 x 25 foot

GSS's

(WAT FB25.) |

|

Production Example Case 2

Weld Start Quality Improved Significantly with Gas Saver System While

Gas Consumption Decreased by 33 to 50%

A shop making large diameter pipe evaluated our Gas Saver System (GSSTM)

in their MIG repair rack. In several tests using cylinder gas supply they

found gas savings ranging from a minimum of 33% to over 50%. This was far

more than enough to justify the purchase. However the biggest cost savings

came from improved weld start quality!

Details of Quality Improvement:

While testing the GSS the quality benefits were clearly

observed by the welder. This shop is often required to ultrasonically test all welds.

Weld repair is made with MIG. These repairs must pass ultrasonic tests. For a repair weld,

starts are a significant part of the deposit. With the standard gas delivery

system, flow peak surge at the start exceeded 220 CFH. With the

GSS

the peak was lowered to under 90 CFH and that for a very short time. The welder who was testing the

system knew this excessive surge flow with his standard system caused starting problems

with internal porosity and stated that

he; “cuts the wire back to the tip and starts with the gun above the work to allow the

initial surge flow in attempt to reduce flow rate before the arc strikes!” The pipe

does not leave his work area until all welds are checked and pass UT. He often was holding up production.

Note: After about a year in production the welder

using the GSS

system reported, with no special starting technique, he found almost no weld start porosity compared to numerous problems previously encountered!

Details of Test:

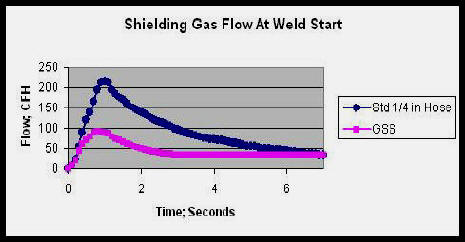

The following shows graphically the peak surge flow measured with their standard

1/4 inch ID gas delivery hose versus our patented

GSS.

Note the

GSS limits the peak surge and quickly returns

flow to an acceptable level preventing air from being pulled into the shielding gas

stream. With their standard 1/4 inch ID hose the flow exceeds 100 CFH for

about 3 seconds. That flow rate is over the acceptable level needed to

maintain quality Laminar flow and will pull air into the gas stream. You

could use preflow to help, but a 3 second preflow not only wastes gas but would

create a very unhappy welder! Would you like waiting 3 seconds

every time you pulled the trigger? We find welders will zero out preflow

even when it is set at 1/2 second! Weld starts with the

GSS

were smooth with less spatter.

Also important, with the

GSS there is still sufficient extra gas delivered quickly at the weld start to

purge the weld start area and the torch nozzle of moisture laden air.

That extra gas is

essential to avoid a similar problems created by having excess flow rate; Click

to See Why.

MAJOR

QUALITY IMPROVEMENT: As important as the shielding gas savings, with

the 5/8 inch diameter welding torch nozzle employed, excess turbulent flow

exists at about 55 to 60 CFH. Turbulence causes air to be pulled into the arc. Air is 73% Nitrogen

and even 2% Nitrogen in the gas shield can cause porosity in the deposit.

With their standard system when welding started, air was being pulled into the

shielding gas stream for several seconds reducing weld start quality. Devices that

eliminate all extra start gas (those installed directly at the feeder) cause

similar problems as the excess gas flow surge. Moisture laden air is

present in the gas shield at the weld start. See

Results of Start Improvement With

GSS

At Fabricator Where Extra Gas Was Not Present.

|

|

Production Example

Case 3a

Results of

the

GSS

Installed in a Small Shop

Even a 250 amp welder can benefit from the use

of the

GSS.

This example is a 250 amp Miller welder with built in feeder. This Street

Rod Builder welds car

frames and accessories. Although the welder and gas cylinder are on a portable cart,

the system was connected with a

conventional 12 ½ foot shielding

gas delivery hose.

This was installed to allow a remote cylinder to be connected when needed such

as when switching to pure Argon for welding aluminum. A regulator/flowgauge is used to set gas flow rates. A pressure

check at the regulator end of the of the gas delivery hose when not

welding showed 30 psi.

The gas flow at weld start

was measured with a specially constructed high capacity rotameter flow meter

mounted over the torch nozzle.

With the original ¼ inch gas delivery hose a gas flow surge of 150 CFH was

measured at the weld start. With the small torch gas cup employed a flow

rate greater than about 40 CFH creates turbulence. Air is then entrained into

the gas stream causing poor weld starts and possibly porosity. This

turbulent flow will take a short time to stabilize to a smooth laminar flow even after

it reaches the

desired preset level.

The

GSS

was easily installed by simply replacing the existing hose and threading on the

GSS

hose fittings (see photo above

right).

Flow surge at the weld start was about 50 CFH with the

GSS

installed and lasted less than a second. With the many short welds made and

frequent inching of the wire at this facility, gas waste and

use will be easily reduced by 50 to 75%. Kyle Bond, President,

indicated a big benefit is the reduced time and effort in changing cylinders less frequently. Since short welds and tacks are the primary use of this welder, the

improvement achieved in weld start quality is also a significant advantage.

Kyle, an excellent automotive painter, was well aware of the effects of

gas surge caused by pressure buildup in the delivery hose when stopped. He

has to deal with the visible effects when he uses the long air hose lines on the

spray gun in his paint booth! It's too bad we can't see the shielding gas

waste as Kyle can the effects of excess pressure when he starts his spray gun!

In fact the amount of excess stored pressure in the paint gun situation is

actually far less than in our welding system! However the paint surge is

visible!

PS:

A customer who purchased a 6 foot

GSS (part number WAT FB6) reports better quality starts and improvement in

"Tank Life," as they phrased their positive comments.

|

Case 3b: Results of the GSS in Home Shop

Beau Straley Improves Weld Quality and Saves Over 60% of shielding gas. He purchased a 4 foot long Gas Saver System (GSS) and reported these gas results:

"I received the GSS in the early part of a large project, building a 12’ x 24’ steel building. Before installing it on my Miller 211C, I had completed about 30% of the total welds, and had consumed approximately 400 psi of my Argon/25% CO2 gas mixture. As my project progressed I could tell I was consuming much less gas, so I increased the flow rate and my weld quality improved. In the following three months I finished all the remaining welds. The remaining 70% of the welds required only an additional 300 psi consumption of gas. Improvement in my welding technique accounts for part of the gas savings, however, considering I more then doubled the number of welds, while reducing my gas consumption by 25%, I’d say the GSS is a real winner! "I received the GSS in the early part of a large project, building a 12’ x 24’ steel building. Before installing it on my Miller 211C, I had completed about 30% of the total welds, and had consumed approximately 400 psi of my Argon/25% CO2 gas mixture. As my project progressed I could tell I was consuming much less gas, so I increased the flow rate and my weld quality improved. In the following three months I finished all the remaining welds. The remaining 70% of the welds required only an additional 300 psi consumption of gas. Improvement in my welding technique accounts for part of the gas savings, however, considering I more then doubled the number of welds, while reducing my gas consumption by 25%, I’d say the GSS is a real winner!

Before I installed the GSS I was being stingy with the shielding gas flow, and the poor quality of my welds proved that. With the GSS installed I was confident that I was not wasting gas, and increased the gas flow rate. The result withas that the appearance and quality of my welds improved dramatically. It not only saved shielding gas, but it increased my confidence. That’s a winning combination in my book!

Thank you for a wonderful product that actually does what you say it will."

Crunching the math for Beau Straley's gas usage: Over Twice The Welds Made/Used 75% of the Gas or 50%/75% = 67% Less Gas Used with GSS! |

Case 3c: Minnesota Welding School Installs 45 Gas Saver

Systems

and cuts shielding gas use over half

The welding

department at a technical college initially installed 30 Gas S aver

Systemsfrom their liquid gas feed

piped supply to their TIG welders and to gas mixers then MIG welders.

After three months of use this is what the instructor reports: aver

Systemsfrom their liquid gas feed

piped supply to their TIG welders and to gas mixers then MIG welders.

After three months of use this is what the instructor reports:

" We went from using 1 Dewar of Argon (liquid

gas cylinder) a week to the same

size Dewar lasting almost 3 weeks. The companies that sit on

my advisory committee are becoming very interested in this upgrade. I will

keep you posted"

They purchased 15 more Gas Saver

Systems for the 2014 -'15 school year.

Note: An advisory committee member, a Caterpillar Tractor plant, has purchased 100 Gas Saver

Systems! |

|

Production Example Case 4

Automotive

Company Installs

GSS's

on

126 MIG Welders

An automotive company tested two

MIG welders equipped with cylinders, one with their standard shielding gas

delivery hose the other with a

GSS

. Initial results looked very promising so they installed Gas

Saver Systems on 68 manual MIG welders. They operate with 0.035 inch diameter

solid wire at about 180 amps for most weld joints. The Argon/CO2

gas mixture is delivered to each welder in a very efficient manifold system

using a large diameter pipe header to ensure uniform gas pressure to each of the

flowmeters. The shielding gas

GSS

delivery hose varies in length from 70 to over 100 feet. An automotive company tested two

MIG welders equipped with cylinders, one with their standard shielding gas

delivery hose the other with a

GSS

. Initial results looked very promising so they installed Gas

Saver Systems on 68 manual MIG welders. They operate with 0.035 inch diameter

solid wire at about 180 amps for most weld joints. The Argon/CO2

gas mixture is delivered to each welder in a very efficient manifold system

using a large diameter pipe header to ensure uniform gas pressure to each of the

flowmeters. The shielding gas

GSS

delivery hose varies in length from 70 to over 100 feet.

Initial results in this three shift operation show over a 30% reduction in total

shielding gas used. This will result in a financial savings of over

$50,000/year. Payback will be measured in months. A significant reduction

in excess gas surge at the weld start is also achieved. Weld start quality

improvements are being evaluated. After a year in production 44 more

systems were purchased for installation during a maintenance shutdown making a

total of 112

GSS's

at this location. They then added they then added 14 more for new MIG welding robots.

Note: If you

want to test our

GSS

on a bulk gas supply you can use several cylinders of shielding gas

but must use a regulator for the test that approximates your pipeline pressure.

Email for Details.

|

|

Production Example Case 5

93

GSS

's Installed

at Structural Aluminum Fabricator

Over 40% Gas saving Found

in Their Tests

After measuring

shielding gas surge flow rates in excess of 250 CFH, a primarily structural

aluminum fabricator conducted a test to define the amount of argon/helium

shielding gas they could save using a

GSS.

Tests were conducted in an area where cylinder gas supply is used.

This allowed a direct comparison to be made with their standard gas delivery

hose on one welding system and a

GSS

installed on another. Both were making similar welds. They found over a 40%

shielding gas savings with the

GSS.

Weld start porosity

was also a problem. Air being pulled into the weld zone by the high surge flow rates was no doubt a significant

contributor to that situation. They installed

GSS

on 93 MIG welders both those welding aluminum as well as on those welding

steel. With the high cost of the argon/helium shielding gas mixture the

payback for the

GSS

investment will be obtained in about one month!

Note: If you

want to test our

GSS

for a bulk gas supply you can perform the test with several cylinders of shielding gas

but must use a regulator for the test that approximates your pipeline pressure

when welding stops.

Email for Details.

|

|

Production Example Case 6

Bar Joist Manufacturer Improves Starts and Saves

Gas

An interesting application of the

GSS validates the need for some extra gas at the weld start. A

bar joist manufacturer was using flow control orifices mounted at the wire

feeders. Argon/CO2 shielding gas is supplied in a pipeline

through about 15 feet of gas delivery hose. The flow control orifice

established the flow at 45 CFH. However the welders wanted higher flow

rates with some even drilling out the orifice! The welding engineer wanted to avoid wasting

shielding gas. With this flow setting arrangement where control is mounted at

the feeder next to the gas solenoid there is insufficient extra gas provided at the weld start.

This lack of extra gas prevents to purging the weld start area of

moisture laden air. An interesting application of the

GSS validates the need for some extra gas at the weld start. A

bar joist manufacturer was using flow control orifices mounted at the wire

feeders. Argon/CO2 shielding gas is supplied in a pipeline

through about 15 feet of gas delivery hose. The flow control orifice

established the flow at 45 CFH. However the welders wanted higher flow

rates with some even drilling out the orifice! The welding engineer wanted to avoid wasting

shielding gas. With this flow setting arrangement where control is mounted at

the feeder next to the gas solenoid there is insufficient extra gas provided at the weld start.

This lack of extra gas prevents to purging the weld start area of

moisture laden air.

A test was made to check weld performance and potential shielding gas

savings using two cylinders of shielding gas on two adjacent welders instead

of their pipeline gas supply. One was set with their

standard flow control orifice system and a regulator providing a pressure

that matched their pipeline, 50 psi. The other with a

regulator/flowmeter (also of a 50 psi design) using a 15 foot

GSS without their flow control

orifice. Both steady state flows were set at 45 CFH. Since welders stand side

by side, it was easy to observe the weld start quality! Instantly the

welder using the

GSS noticed improved

starting. After about an hour with observably better results the

welding engineer suggested we lower the shielding

gas flow on the welder with the

GSS to 35 CFH! The same improved weld start quality

was observed and the welder was "happy." In

fact even though we lowered the steady-state flow to 35 CFH there was still

about the same controlled amount of extra gas available at the start (that

stored in the GSS

hose when welding stopped.) The higher start gas flow rate established by the

surge flow orifice in the

GSS

maintained

the higher flow at the start.

This higher start flow rate quickly flooded and purged the weld start area of

moisture laden air.

It was this air that was casing

excess spatter and lack of shielding on all their other welders! After about 4 hours of observation it was obvious the spatter

at the weld start was less with the GSS.

We also measured a reduced use of shielding gas of 25+%.

After several months of testing to check this one system during windy days etc,

this shop now has

GSS's installed on all 50 welders!

Pipeline pressure was set to provide the steady state flow rate desired. Bottom Line - - "Some extra

gas flow at the start is very beneficial." In addition, after about a year

of use their bulk gas supplier called to see if their business had turned down since

they were using 30+% less gas- it had not!

(Note, the best way to look at weld start quality and spatter

generation is NOT to look though a welding lens! BE CAREFUL, but block

the arc with a piece of cardboard or a gloved hand and lower it until just

the arc is blocked. You can then see the amount of spatter clearly!

Remember the excess spatter is an indication of the problem being caused by

moisture laden air in the gas stream.)

Also note that any flow control device installed right at the feeder, be

it an orifice flow control or a flowmeter will have the same lack of

sufficient initial shielding gas to purge the weld start area.

An interesting side note from this bar joist manufacturer: When evaluating

the fittings they would need for their 45 MIG welders, it was observed that one installation had

a low pressure "Gas Guard" regulator / flow control device mounted at the

feeder. It had an output pressure gauge calibrated in CFH (Photo Right). The maintenance manager indicated these had been installed on all welders

several years before at a

cost much higher than the

GSS and had to be removed due to inconsistent results. The one

remaining was

adjusted at a very high flow rate according to the flow gauge reading. The maintenance

manager indicated it would not be

reinstalled and was surprised it was still there!

See information that defines why they probably experienced these problem! installation had

a low pressure "Gas Guard" regulator / flow control device mounted at the

feeder. It had an output pressure gauge calibrated in CFH (Photo Right). The maintenance manager indicated these had been installed on all welders

several years before at a

cost much higher than the

GSS and had to be removed due to inconsistent results. The one

remaining was

adjusted at a very high flow rate according to the flow gauge reading. The maintenance

manager indicated it would not be

reinstalled and was surprised it was still there!

See information that defines why they probably experienced these problem!

See

another report from a welding engineer who had to remove 32 low pressure devices

from his production lines.

Unfortunately we have had other potential

users of our GSS not want to try the

system because of poor experience with other "gas saving products" causing weld

or welder acceptance problems. Although the patented

GSS is very simple it

does not create the problems caused by a number of other devices. It does

not alter the delivery pressure so automatic flow compensation is maintained.

Unlike simple orifices that restrict flow it does provide a controlled amount of

extra shielding gas at the weld start. The welder still has control of the

flow, it does not limit their ability to set the flow needed. They don't

have to "drill out" a flow limiting orifice!

(If

your welders are setting excessive flow rates, see our Flow Rate Limiter

Product.)

BE CAREFUL SOME OF THESE

DEVICES DO NOT MENTION THAT THEY LOWER PRESSURE!! ALSO ANY DEVICE THAT

MOUNTS DIRECTLY AT THE FEEDER WILL NOT PROVIDE SUFFICIENT EXTRA START GAS.

EMAIL IF YOU HAVE A QUESTION ABOUT A SPECIFIC MODEL

See

Another Bar Joist

Company Survey where they mounted flowmeters at the wire feeders to reduce

surge. They had insufficient extra gas at the start and used increased

flow rates to try to compensate - wasting gas!

|

|

Production Example Case 7

Texas Truck Storage Box Manufacturer Welds 2.7

Times More Parts with Gas Saver System; a 63% Gas Savings

A Texas based

manufacturer of various types of truck storage boxes purchased a 25 foot Gas

Saver System (WAT FB25) to check for shielding gas savings. They picked a

repetitive job, welding doors, and started with a full cylinder of gas.

Welding with 0.035 solid wire MIG, using their standard gas delivery hose, 236

doors were completed with that cylinder. Putting on a new cylinder and the

GSS,

632 doors were welded before the cylinder was empty! That is 2.7 times

more parts. A Texas based

manufacturer of various types of truck storage boxes purchased a 25 foot Gas

Saver System (WAT FB25) to check for shielding gas savings. They picked a

repetitive job, welding doors, and started with a full cylinder of gas.

Welding with 0.035 solid wire MIG, using their standard gas delivery hose, 236

doors were completed with that cylinder. Putting on a new cylinder and the

GSS,

632 doors were welded before the cylinder was empty! That is 2.7 times

more parts.

The

gas savings can be stated several ways. In the base test, with the normal gas delivery hose 300 CF of gas

was consumed welding 236 parts. With the

GSS

they consumed only 300 CF x 236/632 = 112 CF for that same number of parts.

Therefore 300 CF-112 CF = 188 CF is wasted with their normal system! And the

GSS

still provides the proper amount of extra gas at the weld start and maintains

the pressure in the hose to automatically compensate for restrictions.

Calculating the gas savings

as a percentage of prior use; (300 -112)/300 = 63% gas savings.

Or said another way it takes 300/112 = 268% more gas to weld the same

number of parts. After these impressive results, 25

GSS's were purchased for the whole shop.

Stated

another way; to weld 632 doors with their standard system theywould have needed 2.7 cylinders versus one with the

GSS !! Stated

another way; to weld 632 doors with their standard system theywould have needed 2.7 cylinders versus one with the

GSS !!

After several years of use they needed

another 10

GSS's

for new MIG welders.

They asked for more "Magic

Hose!"

|

|

Case 8

Pipe Fabricator Saves 41%

in Shielding Gas; Installs 215 Systems

A Mid West Pipe

Fabricating Shop tested a number of systems to determine how much shielding gas

could be saved while maintaining their high quality standards. The

Gas Saver System came out on top with 41% gas savings. A Mid West Pipe

Fabricating Shop tested a number of systems to determine how much shielding gas

could be saved while maintaining their high quality standards. The

Gas Saver System came out on top with 41% gas savings.

They selected a

repetitive job for the test. With their standard gas delivery hose they used 32

pounds of flux cored wire with a full cylinder . With the

GSS

installed and a new cylinder, with all

the same welding conditions and part, 53 pounds of weld metal were

deposited! That calculates to a 41% gas savings. The

GSS

also supplied a controlled amount of extra gas on weld initiation for quality

starts and retained the ability to automatically compensate for flow

restrictions (which

low pressure systems do not!) Since their test was made with a

shorter gas delivery hose than will be required on most weld stations, their gas

savings will be even greater!

This shop uses a

number of dual MIG feeders to handle, for example, solid steel wire on one side

and stainless on the other. Both may require different gas mixtures.

A TIG system is included on many stations for root welds etc requiring a

different shield gas. For many of the weld stations that means

three separate gas lines running about 25 feet back to their respective gas

supply .

They purchased 115

GSS's

to equip their whole shop.

Two years later they expanded their operation and

ordered 80 more systems and another 20 in December 2012 after 4 more

years. When placing the last order it was mentioned they were very pleased

with the gas savings results and the durability of the

GSS.

|

|

Production Example Case 9

Major Trailer

Manufacturer Saves 25% in Production

Installs 71 Systems

A major US producer

of Trailers purchased two 25 foot Gas Saver Systems to evaluate in one of their

production plants. They found significant savings in their test

and purchased a total of 71 systems. Six months later they report a

shielding gas savings of 25% in production. They are now

broadcasting the word to their other plants.

With Argon price

increases of 25 to 40% publicly announced over the past 2 year this allowed cost containment to

maintain their competitive edge.

|

|

Production Example Case 10

6 Foot Delivery Hose Can Still Save 25 to

40+% Shielding Gas

A

manufacturer of automotive exhausts uses over one hundred Robot Welders.

They have only a 6 foot shielding gas hose from the flow control at the gas

source to solenoid! After a number of tests of the Gas Saver System (GSSTM)

conducted during a Black Belt Lean Manufacturing Study

they measured from 25 to 40+% shielding gas savings depending on the

specific weldment. They have installed

GSS's on all 128 of their

Robotic Welders! They recently installed our patented

Flow

Rate Limiter and Lock to control the flow set on

their pipeline flowmeters. This device fits most US made

flowmeters and regulator/flowmeters. A

manufacturer of automotive exhausts uses over one hundred Robot Welders.

They have only a 6 foot shielding gas hose from the flow control at the gas

source to solenoid! After a number of tests of the Gas Saver System (GSSTM)

conducted during a Black Belt Lean Manufacturing Study

they measured from 25 to 40+% shielding gas savings depending on the

specific weldment. They have installed

GSS's on all 128 of their

Robotic Welders! They recently installed our patented

Flow

Rate Limiter and Lock to control the flow set on

their pipeline flowmeters. This device fits most US made

flowmeters and regulator/flowmeters.

In addition, the controlled

amount of shielding gas delivered at the weld start, at a flow rate that does not

pull air into the gas stream, can eliminate the need for preflow.

Preflow is sometimes used in an attempt to circumvent initial high gas surge causing

air aspiration and resulting inferior weld starts. This is

particularly a problem with Pulsed MIG welding. With the

GSS optimum starts are achieved

without wasting valuable cycle time and shielding gas.

Since the

GSS retains gas delivery pressure, automatic flow

compensation is maintained. This is critical in Robotic Welding operations where

high duty cycles can clog welding torch gas passages with spatter and debris from the

welding wire. A reduction in flow occurs if

this feature is not maintained (as occurs with low pressure

systems See

Details of This Feature.)

Another

Robotic Welder User Purchases 60

GSS's

A manufacturer of automotive

seats installs 60

GSS systems. They also have short gas

delivery hoses on their Robotic Welders and find the gas savings very

significant.

Robotic users show that

even with a short gas delivery hose, the standard size provides excess

shielding gas and excess gas flow at the weld start. |

|

Production Example

Case 11

350 Gas Saver Systems Purchased by Military Sub Supplier

A

manufacturer

supplying fabricated steel and aluminum parts for use in military components

purchased 350

GSS's as they switched from cylinder to pipeline

shielding gas supply. They evaluated the

GSS and in addition to shielding gas savings they found the hose was very rugged and well suited to

their tough environment. They needed new hose to connect to their

pipeline. Since our

GSS did not cost much more then conventional hose they

followed our "Just Do It" statement in our PayBack

calculation page (CLICK TO SEE).

They understood its ability to reduce gas waste since they were aware of the

gas surge that occurred with their cylinder gas supply. With the

higher pipeline pressures the gas waste caused by the start surge could be 50%

higher. The

GSS saves 80+% of the gas waste and improves weld

starts. It provides a controlled amount of extra gas at the start to

quickly purge air from the weld zone and torch nozzle. The starting

gas flow rate is controlled to prevent air from being pulled into the

shielding gas stream. Pipeline pressures would be above the 25 psi

minimum required to maintain automatic flow compensation.

|

|

Production Example Case 12

Texas

Hydraulics Saves 35% with Flow Rate Limiters

See Texas Hydraulics shielding gas savings and weld quality improvement

article published in the December 2006 issue of Trailer Body Builders

Magazine.

CLICK HERE or on Photo of Magazine Cover

Texas Hydraulics

utilizes MIG Welding to fabricate hydraulic cylinders with bores ranging

from 1 inch to 15 inches; with some 20 feet long. Doug Watkins,

Welding Engineer for their Texas plants, found their welders were able

to adjust flowmeters at any time at a shielding gas flow beyond the range of

their Welding Procedure Specification (WPS). Some were found with the

flow measurement ball pinned to the top of the flow tube. Mr. Watkins

indicates, “We have found with our flowmeters that can mean a flow rate of

100 CFH or higher is being used. In addition to the gas waste, any flow

setting beyond about 50 CFH with our electrode extension pulls air into a

turbulent gas shield. That air creates weld spatter and possibly internal

(or even external) weld porosity.” Texas Hydraulics

utilizes MIG Welding to fabricate hydraulic cylinders with bores ranging

from 1 inch to 15 inches; with some 20 feet long. Doug Watkins,

Welding Engineer for their Texas plants, found their welders were able

to adjust flowmeters at any time at a shielding gas flow beyond the range of

their Welding Procedure Specification (WPS). Some were found with the

flow measurement ball pinned to the top of the flow tube. Mr. Watkins

indicates, “We have found with our flowmeters that can mean a flow rate of

100 CFH or higher is being used. In addition to the gas waste, any flow

setting beyond about 50 CFH with our electrode extension pulls air into a

turbulent gas shield. That air creates weld spatter and possibly internal

(or even external) weld porosity.”

By installing 30 WA Technology Flow Rate

Limiters (WAT FRLL) and limiting

the maximum flow that can be set, they assured a quality shielding gas

stream and eliminated gas waste. The maximum flow rate is now set at 40 CFH

and this setting locked-in. After an initial gas use audit, the calculated

shielding gas savings was measured at 25%. With follow up audits the actual

savings exceeds 35%.

Texas Hydraulics also has begun changing

its shielding gas delivery hoses to the Gas Saver

Systems. During their initial testing they showed an 18% reduction

in shielding gas use with less initial gas surge.

According to Mr. Watkins, “By using the

Flow Rate Limiters we are building a quality product and controlling our

consumable cost which continues to be more valuable every day. By switching

to the new Gas Saver Systems we expect to show greater than 20% additional

savings due to the frequent starts and stops. I really appreciate your

companies’ assistance; it helps me do better at my job. WA Technologies has

contributed directly to helping us control our cost in welding consumables

and help us remain competitive in our effort to provide the best product for

the right price.”

|

|

Production Example Case 13

Fabricator in Mexico Saves

30% and 42% Shielding Gas with GSS and Purchased 115 Systems

A

fabricator making chillers in Mexico (who is part of a large US based

company) saw the need to reduce shielding gas waste and improve weld

quality. The welding engineer tested a12 foot

GSS on

several jobs to see what savings they might achieve. The savings

ranged from a low of 30% and a high of 42% easily justifying the investment.

They now have 115 systems and will enjoy the benefits. They also make

excellent use of our Portable Flowmeter (

WAT PFM ) to check flow at the inlet

to their wire feeders and then at the torch. They recently found a

significant flow reduction caused by a clogged torch. Even after

changing the liner the flow loss was still excessive. Replacing the

torch with a new one solved the problem! A

fabricator making chillers in Mexico (who is part of a large US based

company) saw the need to reduce shielding gas waste and improve weld

quality. The welding engineer tested a12 foot

GSS on

several jobs to see what savings they might achieve. The savings

ranged from a low of 30% and a high of 42% easily justifying the investment.

They now have 115 systems and will enjoy the benefits. They also make

excellent use of our Portable Flowmeter (

WAT PFM ) to check flow at the inlet

to their wire feeders and then at the torch. They recently found a

significant flow reduction caused by a clogged torch. Even after

changing the liner the flow loss was still excessive. Replacing the

torch with a new one solved the problem!

They are also evaluating our new

Flow Rate Limiter.

|

|

Production Example

Case 14

Manufacturer of

Irrigation Pipe Saves Over 40% and Installs 120

GSS's

A

company welding pipe flanges on various diameter irrigation pipe evaluated

the

GSS to determine what shielding gas savings they could

achieve. A

company welding pipe flanges on various diameter irrigation pipe evaluated

the

GSS to determine what shielding gas savings they could

achieve.

Although the 120 MIG welders in the

shop are on pipeline gas supply they employed several cylinders of the same

shielding gas to get accurate usage measurements. Utilizing a

regulator/flowmeter having a pressure equal to their pipeline pressure

provided convincing results. On one size pipe they were able to weld 139

more joints with the

GSS installed with a full cylinder compared to their

standard gas delivery hose. On a larger diameter pipe 79 more flanges were

welded. Overall they achieved over a 40% reduction in gas use. The payback

was easily justified and they purchased systems for all their MIG welders.

Want to evaluate a GSS

for your application?

-

Just measure the

length of your existing gas delivery hose from feeder to gas supply and

order a similar length GSS.

-

If on cylinder gas

supply just be sure to use the same brand/model regulator/flowmeter of

flowgauge/ regulator if you’re going to use more than one weld station for

comparison. Compare the number of similar weldments made with existing

and

GSS or measure the weight of wire used with a full

cylinder with each system and obtain pounds wire used per cylinder of gas.

-

If you’re on bulk

gas supply simply purchase two cylinders of the same gas your currently

using. Use regulator/flowmeters that have the same outlet pressure when

welding stops as your pipeline pressure. Email if you want to know which

to purchase.

|

|

Production Example Case 15

Bucyrus

Machinery China Orders Fitted

GSS's

After several months

of use a Second Order was placed. They now have 50 systems.

Bucyrus Langfang

Machinery Co. Ltd in China

(now part of Caterpillar Tractor) sent pictures of the hose fittings on their wire feeders and flowmeters. As expected

they were not CGA 032 "B" inert gas fittings. They asked how they

should order fitted GSS's. The

answer- just order the lengths needed and send an email

or

note with the order-"Splice Fittings Required Both Ends." We sent fitted FB or

note with the order-"Splice Fittings Required Both Ends." We sent fitted FB

hoses

with splice fittings (as shown in the photo above right.) The fitting on the

feeder end included a peak flow limiting orifice. They simply spliced

into their feeder and flowmeter hoses by cutting them about 2 inches from

the existing fittings and inserting the hose barbs supplied with the

GSS. Gas savings performance is the

same as with standard CGA 032 fittings. hoses

with splice fittings (as shown in the photo above right.) The fitting on the

feeder end included a peak flow limiting orifice. They simply spliced

into their feeder and flowmeter hoses by cutting them about 2 inches from

the existing fittings and inserting the hose barbs supplied with the

GSS. Gas savings performance is the

same as with standard CGA 032 fittings. |

|

Production Example Case 16

A

manufacturer of fabricated steel products related to compacting, storing and

transporting waste has production facilities in many locations. After

testing for savings, six of the plants have installed 288 GSS's. Gas savings tests showed from

41 to 47% savings with some performed with shorter gas delivery hoses

than used in production. Longer gas delivery hose lines create greater

shielding gas losses and therefore

yield more savings when GSS's are

installed. The initiative to purchase for all the plants is of

interest and came from: A

manufacturer of fabricated steel products related to compacting, storing and

transporting waste has production facilities in many locations. After

testing for savings, six of the plants have installed 288 GSS's. Gas savings tests showed from

41 to 47% savings with some performed with shorter gas delivery hoses

than used in production. Longer gas delivery hose lines create greater

shielding gas losses and therefore

yield more savings when GSS's are

installed. The initiative to purchase for all the plants is of

interest and came from:

|

In 2010, one plant manger, after seeing our web

site, purchased a GSS and

conducted gas savings tests. He purchased 44 for all his MIG welders

(Note they purchased another 12 for new MIG welders in 2012.) |

|

The regional president told each plant in his

area to

purchase a GSS and conduct their

own tests! We worked mostly with the plant managers who knew they

would be asked by the corporate president about their results. There

were careful to set their tests to get accurate results. That is

how we were able to obtain the excellent savings results data. |

|

The manager of Operational Excellence for the

company was also helpful. |

Note: In 2012, two plants ordered

another 1000 feet of GSS hose with

fittings. |

|

|