|

Friction Stir

Welding (FSW)

History

In 1991 a novel welding method was conceived.

The process was named Friction Stir Welding (FSW) by the inventors at The

Welding Institute (TWI.) TWI is one of the worlds leading independent

research and technology organization and is based in Cambridge, England.

A US patent for FSW, # 5,460,317, was filed in November

1992 with W. H. Thomas et al as inventors, assigned to TWI. A

number of companies around the world are using the process in production,

primarily for joining aluminum. |

|

The Process

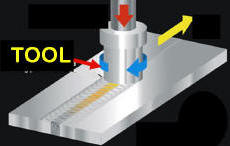

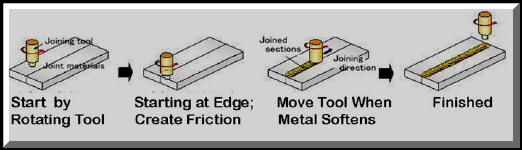

FSW

employs a rotating cylindrical "tool" rubbing against a butted

joint between to pieces to be joined. Friction between the "tool" and

the material heats the joint to a temperature where it becomes soft and

plastic but well below the melting point. The "tool" is then

pushed along the joint line. The parts have to be securely clamped in a manner that prevents the

abutting

joint faces from being forced apart. The softened material in front of the

"tool" is pulled or dragged to the trailing edge. It

leaves a solid phase bond between the two pieces. For many

aluminum alloys the fact that the material is not melted may allow very high

weld strength compared to low joint efficiency with arc welding. The above

picture is a schematic of the process sequence. abutting

joint faces from being forced apart. The softened material in front of the

"tool" is pulled or dragged to the trailing edge. It

leaves a solid phase bond between the two pieces. For many

aluminum alloys the fact that the material is not melted may allow very high

weld strength compared to low joint efficiency with arc welding. The above

picture is a schematic of the process sequence. |

There is not much heat

involved outside the actual joining area . An interesting

anecdote involves my first observation of the process in operation. It

was at an ESSEN Welding Fair in Germany. Five or six foot long pieces

of ~3/8 inch thick aluminum were being butt welded. Typical of my

observation of allowed unsafe practices in Europe (compared to the US,) there were no guards or ropes

around the FSW machine! Show visitors were standing very close, shoulder

to shoulder

along the length of the weldment. As the rotating welding "tool"

passed in front of them, one person touched the welded plates about 18 inches

after the "tool" had passed. Then one by one, others next to him touched

the plate, getting closer and closer to the rotating "tool." Finally one

touched about 6 inches behind the slow moving "tool" and quickly pulled back

like a child contacting a hot stove! involves my first observation of the process in operation. It

was at an ESSEN Welding Fair in Germany. Five or six foot long pieces

of ~3/8 inch thick aluminum were being butt welded. Typical of my

observation of allowed unsafe practices in Europe (compared to the US,) there were no guards or ropes

around the FSW machine! Show visitors were standing very close, shoulder

to shoulder

along the length of the weldment. As the rotating welding "tool"

passed in front of them, one person touched the welded plates about 18 inches

after the "tool" had passed. Then one by one, others next to him touched

the plate, getting closer and closer to the rotating "tool." Finally one

touched about 6 inches behind the slow moving "tool" and quickly pulled back

like a child contacting a hot stove! |

|

TWI holds a number of patents related to

FSW. Anyone using the process

needs permission (a license) from TWI. It is TWI's policy to grant

non-exclusive licenses to any potential users on reasonable commercial

terms. (Note: A former colleague and good friend Dr. Robert John retired

as the CEO of TWI in July 2010. Bob was CEO for 6 years and was

previously the Institutes business

manger. He developed the license arrangements which allowed TWI to generate

and expend the monies needed to advance the science of the process-which

they did and continue to do.) |

| Friction Stir

Welding Applications Although FSW is being developed and

has been used to some extent for a variety of base materials; it's success

to-date has been joining aluminum.

Marine Construction The shipbuilding industry was one of the first to adopt the process. FSW is useful for decks, sides bulkheads and floor panels; for aluminum

extrusions; helicopter landing platforms; masts and booms. |

ESAB

FSW

in Sweden

ESAB’s trade name for

FSW is

SuperStir.™ This machine is installed at Sapa in Sweden. It is used to make

large panels in welded lengths of up to 45 feet for ships etc. The machine

has three welding heads, which allows welding from two sides of the panel at

the same time. The heads can be positioned on the same side of the panel and

starting at the center of the workpiece weld in opposite directions from

each other. |

|

ESAB FSW in

Norway

This ESAB SuperStir™ is installed

at Marine Aluminum Aanen seen

& Co. It is used mainly for manufacturing panels for ships and

railcars. Maximum panel size 50 x 20 feet. Aluminum alloys ranging in

thickness from 1/16 to 5/8 inches are weldable in one pass. The plant

incorporates automatic material handling systems to keep high operating

rates. The welding operation is fully automatic and all parameters are

computerized with an easy to use Man Machine Interface. Production started

in the autumn of 1996 and has produced over 500,000 feet of weld. seen

& Co. It is used mainly for manufacturing panels for ships and

railcars. Maximum panel size 50 x 20 feet. Aluminum alloys ranging in

thickness from 1/16 to 5/8 inches are weldable in one pass. The plant

incorporates automatic material handling systems to keep high operating

rates. The welding operation is fully automatic and all parameters are

computerized with an easy to use Man Machine Interface. Production started

in the autumn of 1996 and has produced over 500,000 feet of weld. |

|

Aerospace Industry

NASA

partnered with Lockheed Martin and MT Aerospace to manufacture the first

full- scale FSW spun-formed tank dome for liquid propellant tanks. The 18 foot

diameter tank dome is made from high strength 2195 aluminum-lithium alloy. FSW allows the use of thinner, high strength alloy reducing weight by 25%

compared to current designs. To achieve the size needed a blank was

constructed by FSW two commercial off-the-shelf plates reducing cost of raw

material. scale FSW spun-formed tank dome for liquid propellant tanks. The 18 foot

diameter tank dome is made from high strength 2195 aluminum-lithium alloy. FSW allows the use of thinner, high strength alloy reducing weight by 25%

compared to current designs. To achieve the size needed a blank was

constructed by FSW two commercial off-the-shelf plates reducing cost of raw

material. |

|

Longitudinal

and circumferential

FSW

are used for rocket booster tanks.

FSW is used

to make the Space Shuttle external tank that contains the liquid hydrogen

fuel and liquid oxygen oxidizer. Prior to using FSW the

7000 series aluminum alloy achieved only 50% joint efficiency with arc

welding. The material had to be made twice as thick and the bulk machined

away leaving a tapered section twice the thickness in the weld joint area.

This created a lot of material waste, excessive time and cost. Longitudinal

and circumferential

FSW

are used for rocket booster tanks.

FSW is used

to make the Space Shuttle external tank that contains the liquid hydrogen

fuel and liquid oxygen oxidizer. Prior to using FSW the

7000 series aluminum alloy achieved only 50% joint efficiency with arc

welding. The material had to be made twice as thick and the bulk machined

away leaving a tapered section twice the thickness in the weld joint area.

This created a lot of material waste, excessive time and cost.

|

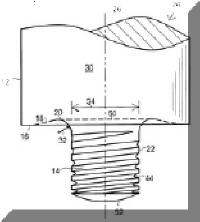

Note: FSW can appear deceptively simple - it is NOT! My group was

involved in the support of the system sold to make the Space Shuttle tanks;

one of the first large systems installed in the USA. The actual welding

process

and simple “tools” (at the time) were not that complicated; the massive and

powerful holding fixture was! The parts must be prevented from moving as

welding progresses. This requires very high forces and that large system

cost over 5 million dollars! In addition, since the mid 1990’s when

that particular system was installed, the “tools” have become more complex. The newest designs can make

quality appearance top and bottom deposits. Some have a

shape which assists moving the softened material from in front of the "tool" to

the rear. (The sketch right is of a

"tool" from a recent patent. The working part called the nib is screw

shaped enhancing movement of the softened material around tool and the upper area

helps form the top surface of the deposit.) process

and simple “tools” (at the time) were not that complicated; the massive and

powerful holding fixture was! The parts must be prevented from moving as

welding progresses. This requires very high forces and that large system

cost over 5 million dollars! In addition, since the mid 1990’s when

that particular system was installed, the “tools” have become more complex. The newest designs can make

quality appearance top and bottom deposits. Some have a

shape which assists moving the softened material from in front of the "tool" to

the rear. (The sketch right is of a

"tool" from a recent patent. The working part called the nib is screw

shaped enhancing movement of the softened material around tool and the upper area

helps form the top surface of the deposit.) |

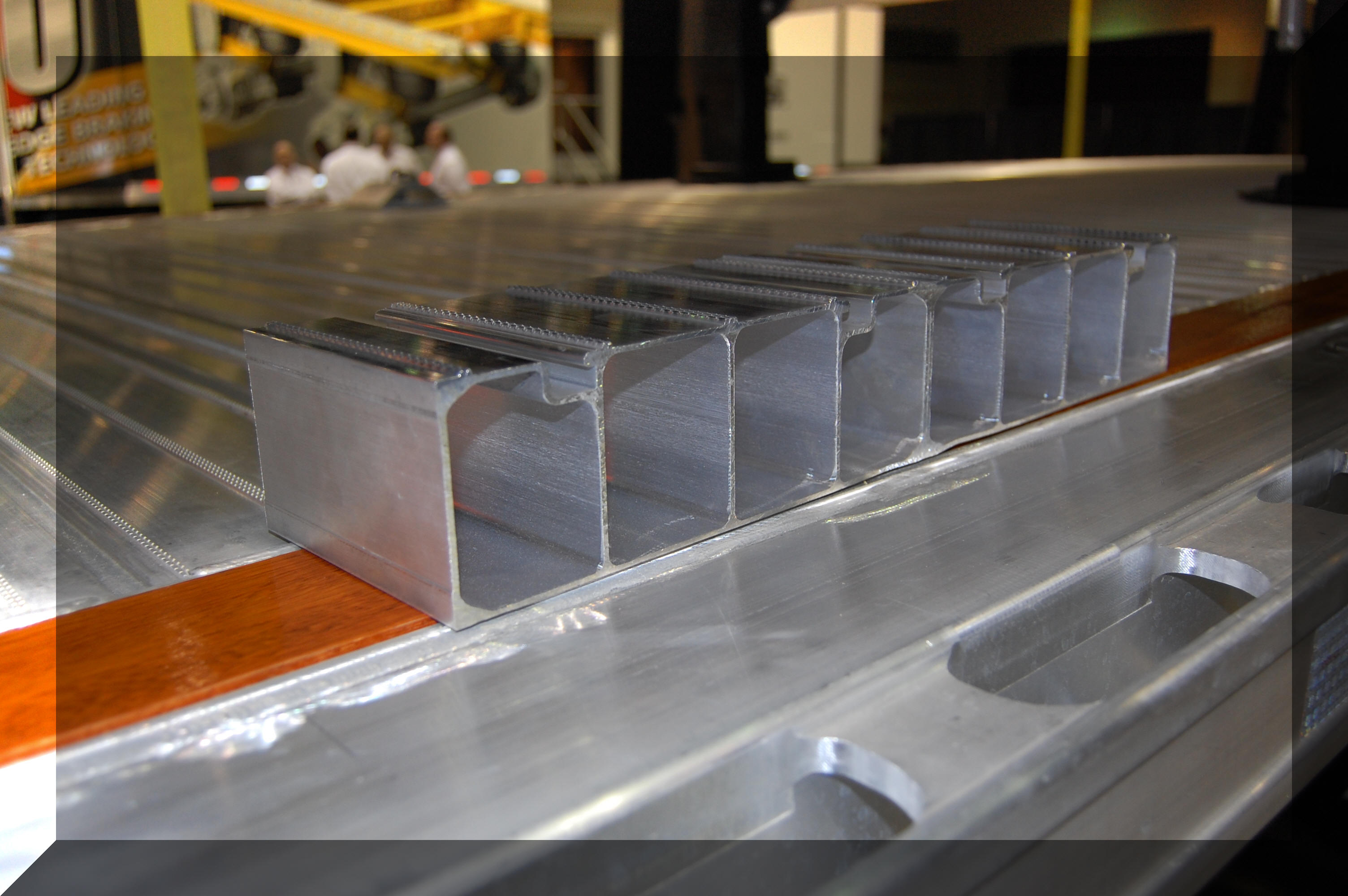

Transportation

Industry Transportation

Industry

Fontain

Trailer introduced

FSW for flatbed trailer manufacture. Market demand for

lighter, stronger trailers to haul more payload was a key reason for a new

design. In addition, lighter weight was needed to compensate for

tractors that are getting heavier due to the additional emission control

technology. Fontain reports the typical 48-foot flatbed weighs about 10,000

pounds and requires 1,400 screws, 44 steel I-beams, eight wing braces, plus

wood and aluminum strips for the flooring – a total of 3,700 parts.

By employing

FSW techniques they reduced the weight of this all aluminum

trailer to 8,000 pounds.

FSW

is also used for welding light weight high speed trains, tank cars etc |

More information on the History of:

-

Submerged Arc

Welding (SAW)

-

MIG Welding (GMAW)

-

Electroslag Welding (ESW)

-

TIG Welding (GTAW)

can be found

at these links on our site (just click on the process).

|

|

Stop

Wasting Shielding Gas!! Stop

Wasting Shielding Gas!!

See YouTube Videos

Including Our Patented MIG Shielding

"Gas

Saver System" (GSS)

Science of MIG

Shielding Gas Flow Control

Why MIG Gas Waste

Detailed Review of GSS

Short Overview of GSS-90 Seconds

What User Say About

GSS

Welding Race Cars

Rat Rods-Then and Now

Welding: Go Green

|

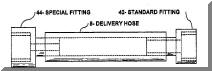

New innovations are still occurring in the welding industry. Our

recent inventions optimize MIG shielding gas flow at the weld start (2003

Patent Number 6,610,957; figure left and 2006 Patent Numbers 7,015,412 and 7,019,248) These devices reduce excess stored gas by over 80%

when welding stops. This significantly reduces gas waste that published

data shows typically exceeds over

60% of what is used! Reducing shielding gas waste can save a

MIG user over 50% of gas use while improving weld start quality. Our

Patent 7,462,709 issued in 2008 and defines a device that allows most

flowmeters to be locked at the desired settings avoiding excess wasted gas.

Reducing waste

is very important in a competitive world environment.

|

|

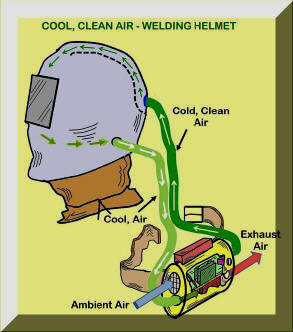

In

2012 we were granted two patents related to helping a welders environment.

These welding helmet designs not only filter the air entering the helmet

they also cool the air using a Thermoelectric Cooling Module. Cooling

the head helps cool the whole body. Excessive heat is a common complaint of

welders. This helmet helps solve the excess heat problem by

providing cooled filtered, breathable air. In

2012 we were granted two patents related to helping a welders environment.

These welding helmet designs not only filter the air entering the helmet

they also cool the air using a Thermoelectric Cooling Module. Cooling

the head helps cool the whole body. Excessive heat is a common complaint of

welders. This helmet helps solve the excess heat problem by

providing cooled filtered, breathable air.

We are searching

for a company to license these designs, including fabricators that

employ a number of welders who would benefit from the reduced heat and

better environment. Contact

Jerry_Uttrachi@NetWelding.com if interested. |

Have a MIG Welder?

Improve Weld Start Quality and

Have Shielding Gas Cylinder Last at Twice as Long!

Note: Our Patented

GSS is Not Available in "Stores"

We Focus on Saving NOT

Selling Shielding Gas"

A home shop fabricator

in Georgia with a Miller TM 175 amp welder

purchased a 50 foot Gas Saver System (

GSS

TM

) so he could use a larger cylinder

and mount it on the wall of his shop. He wrote:

"The system works great.

Thanks for the professional service and

a great product."

Click To See His Home Shop

A Professional

Street Rod Builder Had This to Say:

With their standard MIG welder gas delivery hose the peak shielding flow at

weld start was measured at 150 CFH. That caused air

to be sucked into the gas stream causing poor weld starts. With the replacing their existing

hose, the peak flow surge at the weld start was about 50 CFH. Total gas use

was cut in half.

Kyle Bond, President, quickly saw the improvement

achieved in weld start quality as a significant advantage! Kyle, an

excellent automotive painter, was well aware of the effects of gas surge

caused by pressure buildup in the delivery hose when stopped. He has to

deal with the visible effects in the air hose lines on the spray gun in his

paint booth! The paint surge is visible and creates defects unless the gun

is triggered off the part being painted! We can’t do that with our MIG gun!

GAS SAVER SYSTEM (GSS TM)

PURCHASE INFORMATION

|