Background Details/History:

Some references

site Robert Hopkins for having invented the Electroslag welding process in the

1930's. Most of his patents relate to Electroslag melting for ingot

manufacture, not welding. However one US patent, number 2,191481 filed in

June, 1939 does describe the surfacing of one material on another. The

illustration, however looks more like a melting

furnace than welding. In fact the fellow who invented Submerged Arc

Welding, Harry Kennedy, was

granted a US patent in October of 1950, number 2,631,344, assigned to Linde

Division of UCC that more closely related to Electroslag welding. However it too

falls short of defining what we know today as this simple welding process.

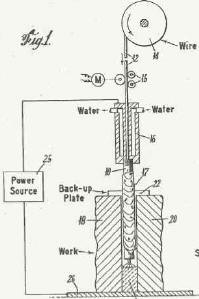

A unique version

of the Consumable Guide

Electroslag Welding Process was developed and patented (US Patent Number

2,868,951 filed in March 1957, assigned to the Linde Division of UCC) by a colleague, Harry Shrubsall.

The figure on the left is from that patent. It clearly shows the

process as it is known today. Harry's patent includes the use of a flux

coated tube to replace part of the flux that plates out on the copper molds.

It also insulates the metal guide tube from the work.

A unique version

of the Consumable Guide

Electroslag Welding Process was developed and patented (US Patent Number

2,868,951 filed in March 1957, assigned to the Linde Division of UCC) by a colleague, Harry Shrubsall.

The figure on the left is from that patent. It clearly shows the

process as it is known today. Harry's patent includes the use of a flux

coated tube to replace part of the flux that plates out on the copper molds.

It also insulates the metal guide tube from the work.

The Paton Institute

in Russia introduced the process and did a great deal of development work. They published a book, "Electroslag Welding" in 1959 with an English

translation published by The American Welding Society in 1962. Of the 92

references sited in that text, most range in dates from 1955 to 1959. The

first mention of Electroslag is in a paper entitled "Electroslag Welding,"

published in Avtomaticicheskaya Svarka in 1953 by Voloshkevich.

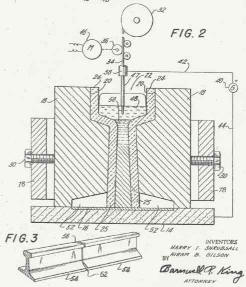

Harry Shrubsall and I worked as engineers in the Linde

Development Labs (although I started after his invention!). Harry had

several subsequent patents on the use of the process to butt weld Railroad Rails.

Patent numbers 3,192,356 and 3,291,955 filed on September 1962 and February 1963

respectively describe Railroad Rail welding with Consumable Guide

Electroslag.

I worked on a Plate Electrode

Electroslag Welding development with Harry, It used a triangular shaped

electrode with two holes that

spread two electrodes at the bottom to weld the Rail Base

then narrowed them to weld through the Rail Web and the Rail Head on top. Welds were excellent and passed all

required Railroad tests. The resulting welds were far better quality than the Thermite deposits often employed but did

take longer to make. This extra time ultimately caused resistance to its

use. If a train happens to be coming down the track, all workers want to

be able to move fast! Can't blame them.

I worked on a Plate Electrode

Electroslag Welding development with Harry, It used a triangular shaped

electrode with two holes that

spread two electrodes at the bottom to weld the Rail Base

then narrowed them to weld through the Rail Web and the Rail Head on top. Welds were excellent and passed all

required Railroad tests. The resulting welds were far better quality than the Thermite deposits often employed but did

take longer to make. This extra time ultimately caused resistance to its

use. If a train happens to be coming down the track, all workers want to

be able to move fast! Can't blame them.

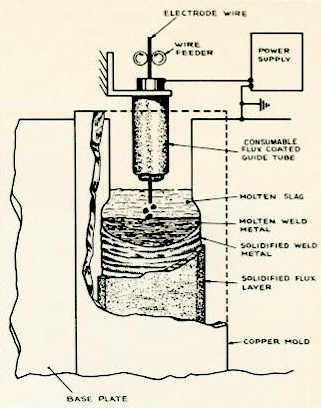

Refer to the schematic below copied from the original Linde

Publication 51-220 "Procedures for Consumable Guide Electroslag Welding." In the

Electroslag Welding process current transfers from the guide tube to the welding

wire and in turn though a molten flux bath. The resistance of the flux

bath creates the heat and temperature that melts the wire and surrounding base

material. The guide tube itself will also contact the molten flux bath

periodically which will cause an increase in welding current as the end is

consumed. The molten flux will solidify on the copper retaining molds

which are placed on the sides on the weld joint. This flux layer protects

the copper molds from having direct contact with the weld.

The Linde Flux Coated Guide Tube defined in Harry's

original patent looked like a big stick electrode! They were made with

a hole down the center and a thin flux coating that protected the tube from

shorting to the plate side walls and also automatically compensated for a

portion of the flux that plated out on the copper retaining shoes. The

tubes were purposely coated with a quantity of flux that was less than the

amount that plated out on the copper molds (see schematic on left showing flux

layer that plates out on the copper molds ) This avoided excess flux build-up in the joint as

welding progressed. Therefore additional flux was always needed and was

added by the operator but far less frequently than when uncoated tubes were

used. ( The concept of adding

flux by listening to the sound, works great in a Laboratory environment.

However in a noisy shop it is not effective. There are

some simple tricks at measuring flux depth.) For multiple tube welding of heavy sections (up to 4 tubes for

8 inch thick plates) a special very thinly flux coated tube (referred to as Type

M) was used so as not

to produce excess flux burden as welding progressed up the joint. Special

slip-on metal guide tube clips centered the tubes and prevented vibration and

shorting. This was possible since the tubes flux coating was an insulator.

Little preparation was needed to center the tubes. Those fabricators that

employed bare tubes could have shorting problems that caused equipment failures

and the worse thing that can happen during an Electroslag weld - - having to

restart!

Linde's patented Flux Coated Guide Tube Process was very successful for the user since a great

deal of welding time and plate preparation were saved. It was also very

successful for Linde who obtained a substantial patent royalty (>

$1/foot of tube) built into the sale of the Flux Coated Guide Tubes. They

were used extensively with some

the notable applications being:

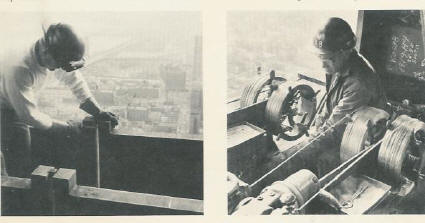

1. Over 1 00,000 feet of Flux Coated Consumable Guide Tubes

were used by Kaiser Steel to

weld massive columns for the Bank of America Headquarters in San Francisco.

This process was very successful and made some difficult to do any other way,

transitions joints. Thin coated tubes were used in locations where there

were only captive steel weld dams. The operator at left is placing a copper dam

on a box beam reinforcing plate. Four Electroslag welds will

secure the plate to the heavy wall box beam. An article entitled

"Electroslag Welding with Consumable Guide on

00,000 feet of Flux Coated Consumable Guide Tubes

were used by Kaiser Steel to

weld massive columns for the Bank of America Headquarters in San Francisco.

This process was very successful and made some difficult to do any other way,

transitions joints. Thin coated tubes were used in locations where there

were only captive steel weld dams. The operator at left is placing a copper dam

on a box beam reinforcing plate. Four Electroslag welds will

secure the plate to the heavy wall box beam. An article entitled

"Electroslag Welding with Consumable Guide on

the Bank of America World

Headquarters Building," published in The Welding Journal in 1968 by

Tommy Agic of Kaiser Steel and Jim Hampton of Linde, mention that a total of

23,000 welds were made for the job. Plate thickness ranged from 1/2 to 5

inches. The massive columns ranged from 26 to 42 feet long. The

operator on the right is making a beam splice joint with the consumable guide

Electroslag process.

the Bank of America World

Headquarters Building," published in The Welding Journal in 1968 by

Tommy Agic of Kaiser Steel and Jim Hampton of Linde, mention that a total of

23,000 welds were made for the job. Plate thickness ranged from 1/2 to 5

inches. The massive columns ranged from 26 to 42 feet long. The

operator on the right is making a beam splice joint with the consumable guide

Electroslag process.

2.

Thousands of feet of Electroslag welds made on the John Hancock

building in Chicago:

(Above

photos

from a Linde publication F-51-220. On right are two simultaneous welds being made on

beam flanges splices on the edge of the John Hancock building under construction. Each

weld is being made with two Linde Flux Coated Guide Tubes. The photo on

the left shows the weld joint being prepared)

3.

12 foot long seams made in 1 ½ to 2 inch steel for the 72 cubic

yard bucket for Texas Gulf Sulfur dragline. A standard sub arc tractor was

used to make these welds with the simple addition of a guide tube holder, see below:

When welded with manual stick electrodes these 12

foot seams required 150 pounds of electrodes and 40 man hours to complete.

With Consumable Guide Electroslag the electrode requirements reduced to 40

pounds and the weld was completed in 1 3/4 hours.

4.

Detailed application information was described in a Welding

Journal Article entitled “Vertical Submerged Arc Welding,” by Paul Masters from

American Bridge Division of US Steel and Bob Zuchowski from Linde (Linde

Publication 52-539).

5. In addition to the high speed conventional Electroslag used at

National Shipbuilding in San Diego (mentioned above), they also made many

hundreds of welds splicing deck stiffeners on Roll-On-Roll-Off ships with Flux

Coated Consumable Guide Tubes. The process was also used for other

applications and other shipyards.

The royalty income derived from the sale of the Patented

Guide Tubes allowed my Welding Process R & D Group to develop numerous applications and

procedures for the Consumable Guide Electroslag Welding Process. At one time we

had 7 engineers/technicians working on the process in our Laboratory. After successfully welding

steel anode bars in an aluminum pot line (with the line in operation) and a market evaluation, we

decided to do extensive research on the welding of massive aluminum busbars used

in aluminum production.

Other companies also introduced Electroslag systems in the

US. Arcos marketed both conventional Electroslag and Consumable Guide

Electroslag products. They produced a plate electrode, some of which were dip coated with

flux as I recall. Arcos also marketed products for an Electrogas process. The Electrogas process utilized a cored wire with flux added to replace that which coated the weld retaining copper shoes.

Hobart developed a simple oscillator which allowed the

welding of heavier plate without the need for additional guide tubes and related

equipment.

Airco marketed an Electrogas process which used a

solid wire and argon based gas mixture. In was used by the Litton Shipyard

in Erie Pennsylvania to make the vertical hull welds in ship tankers.

Lincoln introduced a vertical welding process which used a self shielded flux cored

wire and operated with moving shoes.