|

|

|

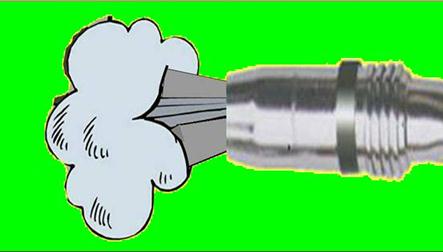

The Blast of Shielding Gas Occurring When a MIG Gun Trigger is Pulled Causes

Problems:

-

Significant Shielding

Gas Waste

-

Inferior Starts Since

Air is "Pulled" Into The Resulting Turbulent Shielding Gas Stream

Our patented

"Go Green"--Gas Saver System

eliminates these problems and saves from 40 to 60% of gas use!

That Saves 8 Tons

of CO2 or Argon Shielding Gas per Year per MIG Welder - SEE

BELOW.

|

Purchase Shielding Gas Saving

Products

|

Payback for Patented

Gas Saver System

and

Patented Flow Rate Limiter

= Less

Than 3 Weeks

See

Payback Calculations |

|

See

"Welding; Go Green" Video

CLICK Here

|

|

If

Excess Gas Flow Is Such A Problem, Why Has My Gas Supplier Not

Told Me? CLICK To See. |

|

The

Gas Saver System (GSS):

|

Is

simple to install; just replace the existing gas delivery

hose

from gas supply to welder or wire feeder with our prefitted

GSS

hose

system. It reduces the gas surge volume by 80% and limits peak surge

flow rate. Works with existing regulator or flow control. You still

control the steady state flow. Is

simple to install; just replace the existing gas delivery

hose

from gas supply to welder or wire feeder with our prefitted

GSS

hose

system. It reduces the gas surge volume by 80% and limits peak surge

flow rate. Works with existing regulator or flow control. You still

control the steady state flow.

|

|

Is

inexpensive. A commonly used 6 foot

GSS

system (Part Number

FB6

)

cost less than $75 and will typical cut shielding gas use by 50% so you'll

have a very quick payback!

|

|

Reduces the gas surge at

the start producing better shielding for sounder welds with less starting

spatter so wasteful repair or grinding may not be needed.

|

|

It

reduces the CO2

waste going into the

atmosphere (even 25% if using 75 Argon/ 25 CO2 ) and also the number of times your gas supplier

will have to expend energy to fill and delivery the ~200 pound cylinders or

to delivery to your bulk tank

|

(Note:

Using MIG gas waste information published in an industrial magazine

quoting a Praxair representative regarding their plant survey finds and

validated with our own observations- one

industrial MIG welder typically wastes over 150,000 ft3 (CF) of

shielding gas

per year. If using straight CO2

that's over 16,000 pounds (8 tons!) of wasted

per welder per year!

If your using Argon gas mixtures your

wasting a similar weight of gas per year per welder and have similar

distribution and much higher production electric energy costs (with

accompanying CO2 pollution)

SEE Why. )

|

|

How

Much Shielding Gas is

Wasted on Each Weld Start or Torch Pull?

What

Causes Shielding Gas Waste?

CLICK TO SEE |

|

CALCULATION OF CO2 WASTE:

Assumptions and

Calculation:

| Industrial MIG welder operating at 50% duty

cycle with flow setting of 35 ft3/hr (CFH) on flowmeter |

| 4 times this amount of

shielding gas needed is wasted. See References below which states

up to 5 times needed is wasted. |

| Then 40 hrs/wk * 50% duty

cycle * 50 weeks = 1000hrs/year arc-on time. |

| Waste consumption = 35 ft3/hr

*4* 1000 hrs/yr = 140,000 ft3 CO2/year |

| 140,000 ft3 CO2

* 0.115 lb CO2/ft3 @ STP (Standard Temperature and

Pressure) = |

| 16,100 lbs = 8 tons of CO2

wasted per year |

| 8 tons/yr wasted. |

References:

-

Standifer, L. R., Shielding Gas Consumption Efficiency.

The Fabricator, Volume 30, Number 6, June 2000.

(States 18 to 30 cubic feet of shielding gas is typically used per pound

of wire consumed. Which is 2.5 to 5 times

the amount that is needed)

-

Weber, R., How to Save 20% on Welding Costs.

Trailer/Body Builders, Volume 44, Number 3, January 2003

(Praxair Representative states, their market survey findings show the average fabricator

consumes 30 cubic feet of gas per pound of wire which 5 times

what is needed.)

|

Welders

Setting Flow Rates Too High? Welders

Setting Flow Rates Too High?

We have measured flow

rates above 125.CFH when the flow ball is

pinned to the top of the tube! Anything over about 50.CFH

is pulling moisture laden air into the shielding gas stream and

causing internal if not visible porosity! The flow rate may be outside

the variable range specified in Procedure Qualifications.

Our Recently Patented

Flow Rate Limiter Locks Flow Setting!

Click on

Picture For More Information |

|

Free Technical Paper, "MIG

SHIELDING GAS

CONTROL"

CLICK ICON for PDF DOWNLOAD |

Purchase Shielding

Gas Saving

Products

Questions? Email

|

|

Some of Our

Other "Green" Web Pages You Might Like to Visit:

|