|

Selecting Filler Metal

Selecting the proper welding filler metal and techniques

requires an understanding of the metallurgy of the base material and the weld metal that develops from an

admixture of the 4130 and the filler metal.

the metallurgy of the base material and the weld metal that develops from an

admixture of the 4130 and the filler metal.

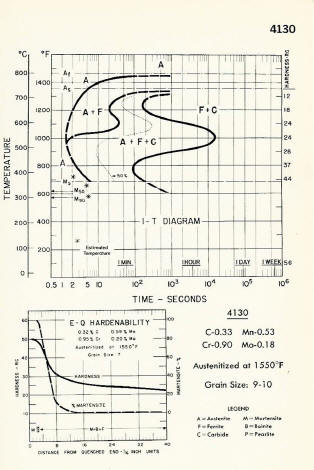

The graph on the left was

taken from a US Steel "Atlas of Isothermal Transformation Diagrams."

These graphs define the metallurgical structure that occurs in various

steels when they are cooled. This one defines that we can expect to

have high hardness, brittle Martensite form when 4130 is cooled at a

particular rate.

The graph at the bottom of the page shows the structure that formed when

a bar of 4130 was heated to 1550 deg F then one end spayed with water.

Note that from about 3/16 inch from the quenched end the microstructure is

almost all Martensite. The hardness in this area is 50 RC. The

equivalent tensile strength for that hardness is about 250,000 psi.

Very strong but also brittle meaning a small crack will easily propagate.

If one made a chisel from that material it would break on the first blow!

If we wanted a chisel we would heat it after quenching to "Temper" the

Martensite to a lower strength and make it far less brittle.

The reason for understanding the 4130 IT diagram, particularly the End

Quench Hardenability Test (Called a Jominy Bar, after the inventor,

Walter E. Jominy) will become apparent as we present additional information

below.

|

|

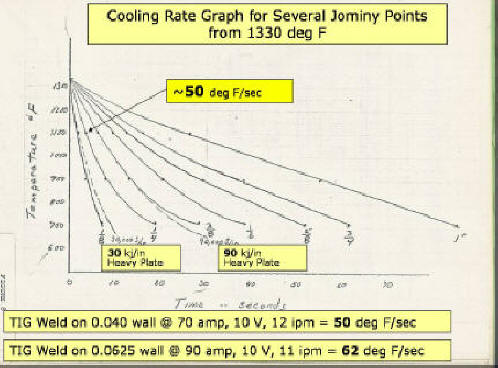

Many years

ago, for a Masters Thesis, I made a Jominy bar from a weld

deposited in a steel that had about 105,000 psi yield and about 120,000 psi

ultimate strength. I also plotted the cooling curves at numerous

points along the Jominy Bar. (No Excel at that time, had to use

graph paper! Note that Walter Jominy only sited cooling rates

at 1100 deg F, not sufficient for my Professor! Had to use a fast

response Light Beam Visicorder, thermal coupes at 1/8 inch intervals along

the bar etc!) Calculations were also made defining the

cooling rate in welds made in 1 inch thick plate with the submerged arc

welding process. The accompanying graph was developed from that data.

The cooling rates for TIG welds made in thin material are also noted on the

graph. Many years

ago, for a Masters Thesis, I made a Jominy bar from a weld

deposited in a steel that had about 105,000 psi yield and about 120,000 psi

ultimate strength. I also plotted the cooling curves at numerous

points along the Jominy Bar. (No Excel at that time, had to use

graph paper! Note that Walter Jominy only sited cooling rates

at 1100 deg F, not sufficient for my Professor! Had to use a fast

response Light Beam Visicorder, thermal coupes at 1/8 inch intervals along

the bar etc!) Calculations were also made defining the

cooling rate in welds made in 1 inch thick plate with the submerged arc

welding process. The accompanying graph was developed from that data.

The cooling rates for TIG welds made in thin material are also noted on the

graph.

|

|

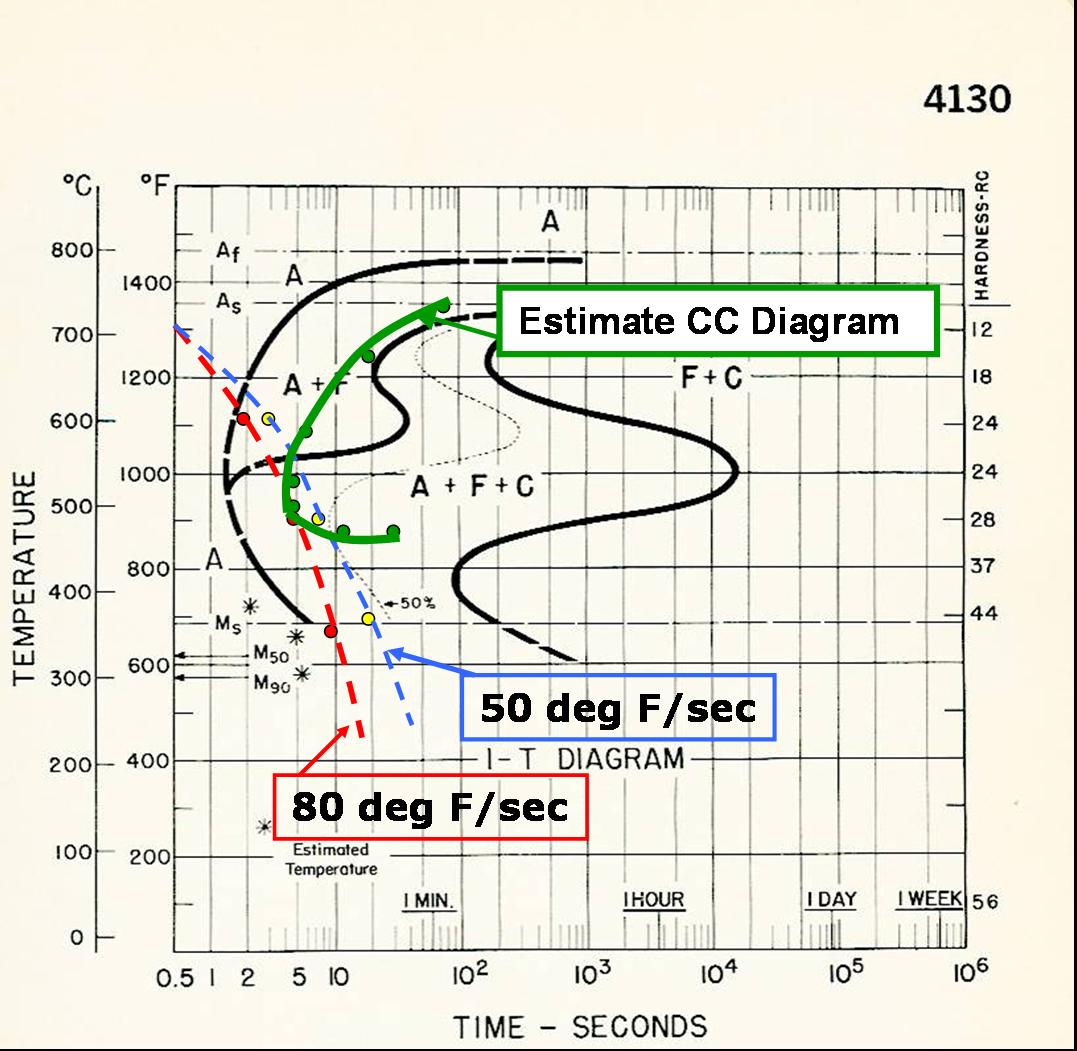

Estimated cooling

rates for several TIG welds in tubing are shown in the accompanying graph in

red and blue lines. The cooling rates are fast since welding volts and amps are relatively

low and the energy efficiency of TIG is low,

about 50%. Calculations for cooling rate are presented on this page:

CLICK.

From the IT

diagram we can estimate a continuous cooling diagram using a technique

suggested by Grange and Kiefer. It is shown with the green line superimposed on the

IT diagram. Also shown is the cooling rate for a TIG weld made on

0.040 inch thick material which is about 50 deg F/sec at about 1100 deg F. For 1/16 inch thick material the TIG cooling rate

would be about 62 deg F/sec, between the two curves. The fast 80

deg/sec cooling rate would occur if small fillets are made on 0.093 inch

thick material. This information is directly related to the weld heat

affected zone (HAZ). These cooling rates can produce some amount of

Martensite in the HAZ. The structure in the weld metal will depend on the weld rod or wire selected as well as

the amount of admixture of 4130. For example, very small fillet welds

may have mostly melted 4130 in the deposit which can create potential

cracking problems.

|

|

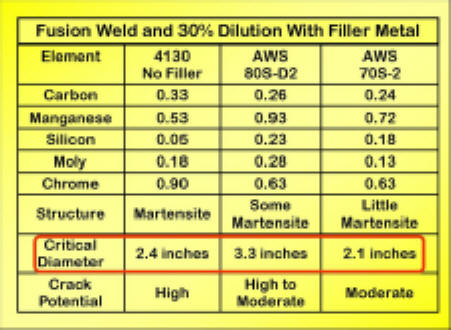

The table

on the left shows the estimated weld metal structure of: 1) a weld made in

4130 without filler metal (called an autogenous deposit), 2) with 30%

ER80S-2 diluted into the 4130 and 3) ER70S-2 rod diluted the same 30% into the 4130. The resulting chemistry

is a simple ratio of the materials assuming TIG welding with Argon shielding gas and

minimum carbon or other

element loss. The table

on the left shows the estimated weld metal structure of: 1) a weld made in

4130 without filler metal (called an autogenous deposit), 2) with 30%

ER80S-2 diluted into the 4130 and 3) ER70S-2 rod diluted the same 30% into the 4130. The resulting chemistry

is a simple ratio of the materials assuming TIG welding with Argon shielding gas and

minimum carbon or other

element loss.

The data showing "Critical Diameter" was developed from a

book on Steel Hardenability by Crafts and Lamont. It defines the

diameter of a bar, that when heated to 1500 deg F and quenched in water

will have 50% Martensite in the center. Notice the deposit with 30%

ER80S-D2 filler rod is much more hardenable than even the 4130.

An austenitized and quenched bar 3.3 inches in diameter of this material would have 50% Martensite

in the center

versus only a 2.4 inch bar for 4130 . The deposit has significantly

higher Manganese and Moly than the 4130 or the deposit made with ER70S-2.

|

|

A deposit made with ER70S-2 in 4139

tubing will most likely have a

slightly lower tensile strength than Normalized 4130. When mixed with

the melted 4130, it will probably be 85,000 to 90,000 psi versus the ~95,000 psi in 4130

depending on how the material was processed. This joint strength can

be increased for intersecting tube joints by making

the fillet size slightly larger.

I have seen

comments on forums about ER70S-2 and ER70S-6 only having a tensile strength

of 70,000 psi. These statement may have been made based on the AWS

designation which indicates a MINIMUM of 70,000 psi is needed

to label the product. That is NOT what is typically found. The following

data is from a TIG weld deposit made with and ER70S-2 rod with essentially

no dilution into the base plate. The information is from published ESAB

data: Tensile Strength was 82,000 psi with a very ductile 31% elongation and

170 ft-lbs Charpy "V" notch impacts at -20 degrees F test temperature. That

is very ductile and tough! When diluted into the high carbon 4130 the strength will

increase.

Conversely, using ER80S-D2 because it contains moly (more than twice that

contained in

4130) may provide a higher strength than needed or desired. For example, an

undiluted weld made with this alloy produced a tensile strength of 110,000

psi and only 22% elongation. ER80S-D2 is often used to weld a Q&T alloy

developed many years ago by US Steel called T-1. It is a structural steel

which has a minimum tensile strength of 110,000 psi, more than normalized

4130 which is typically 95,000 psi. It also has only about 0.15 carbon

making it easier to weld. The 80 in the ER80S-D2 designation does not

define what the actual strength of a deposited weld made with that alloy

will produce-only the minimum to be able to label the product with that

designation.

WELD QUALITY

It is very important to check

weld quality and understand the types of defects that could be encountered when

welding 4130.

Check your weld procedures and keep them consistent. You should make some

sample welds and bend them to destruction to assure failure occurs only after

considerable bending has taken place. Look for porosity or cracks that may

have been present in the weld. It would be a wise investment to hire the

services of an American Welding Society

(AWS)

Certified Welding Inspector (CWI). There are over 20,000 registered.

In fact many of them are members of the 60,000 member AWS. They can

advise on procedures and what to check for such as small undercuts at the weld

toe of fillet welds that can lead to premature failure.

Consistently following the

proper weld procedures and knowing how to check for possible weld problems is of

major importance. Be sure to employ the skills of a qualified

welder who has experience welding this material. Also inspection of the

final welds by an Certified Welding Inspector (Certified by The American Welding

Society) is highly recommended.

|

|

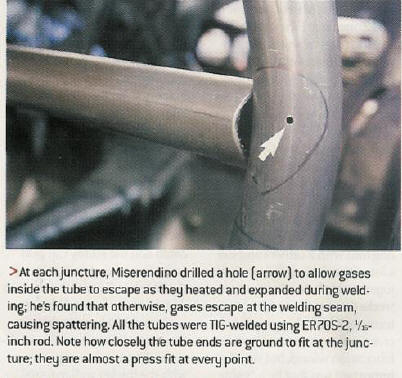

This

is a photo from an interesting article in the March 2007 issue of "Hot Rod

Magazine." The whole ridged elaborate cage was made from 4130 tubing. This

is a photo from an interesting article in the March 2007 issue of "Hot Rod

Magazine." The whole ridged elaborate cage was made from 4130 tubing.

Note they used ER70S-2 welding rod

and made all joints with TIG welding. Have to believe this was a

mocked up photo since the description says the tube ends were ground to

almost a "press fit." This is far from that and unacceptable for

making any type of weld!

Cleaver idea to use the drilled

hole to relieve hot gases in closed tubing joints. |

|

An

article in the April 2010 issue of the AWS Welding Journal entitled "Best

Practices for GTAW (TIG Welding) 4130 Chrome-Moly Tubing"

defines welding parameters and practices need to make quality welds

in race car tubing joints. It defines practices used by a race car

shop. They also recommend ER70S-2 welding rod for most welding

and when high strength is needed, with a sacrifice in ductility, ER80S-D2.

The article states that excellent fit up is essential. They provide a rule of

thumb for setting welding amperage of using 1 amp per 0.001 inch of wall

thickness. This suggests 35 amps for 0.035 inch and 80 amps for 0.080

inch wall thicknesses. Gas flow of 15 to 20 CFH is suggested.

They mention the use of a "Gas Lens" and a small cup size so the tungsten

electrode can protrude out further for visibility and access to the joint.

Welding in 4 quadrants; two

90 deg segments opposite each other than completing the remaining two

segments is recommended. They suggest using smaller rod diameters, generally no

larger than the wall thickness. The article presents a number of other

suggestions regarding welding conditions from a company with successful

experience. Slow pulsing is suggested either with a foot control or

pulse settings built into the welder. An

article in the April 2010 issue of the AWS Welding Journal entitled "Best

Practices for GTAW (TIG Welding) 4130 Chrome-Moly Tubing"

defines welding parameters and practices need to make quality welds

in race car tubing joints. It defines practices used by a race car

shop. They also recommend ER70S-2 welding rod for most welding

and when high strength is needed, with a sacrifice in ductility, ER80S-D2.

The article states that excellent fit up is essential. They provide a rule of

thumb for setting welding amperage of using 1 amp per 0.001 inch of wall

thickness. This suggests 35 amps for 0.035 inch and 80 amps for 0.080

inch wall thicknesses. Gas flow of 15 to 20 CFH is suggested.

They mention the use of a "Gas Lens" and a small cup size so the tungsten

electrode can protrude out further for visibility and access to the joint.

Welding in 4 quadrants; two

90 deg segments opposite each other than completing the remaining two

segments is recommended. They suggest using smaller rod diameters, generally no

larger than the wall thickness. The article presents a number of other

suggestions regarding welding conditions from a company with successful

experience. Slow pulsing is suggested either with a foot control or

pulse settings built into the welder.

TIG welding (also called Heliarc welding an ESAB trade name) or the official AWS designation, Gas Tungsten Arc

Welding (GTAW) requires more skill than MIG welding. However it allows

separate control of welding heat and metal addition. Currents can be

set at very low levels for thin material allowing the operator to watch the

puddle and assure complete weld penetration. |

|

If a Searc Engine Found This Page 1st- - - We'd Suggest

a Visit to The Basic Welding 4130 Page; Then Return. Click

Here

This page presents the technical information that supports

the reasons for the suggestions found on the "Basic, Welding 4130" page.

Like Math?

Want to

see the calculations for weld cooling rates and references?

CLICK

HERE.

Check Out Welding

Math Site |

|

|

Book:

"Advanced Automotive Welding"

Author: Jerry Uttrachi

(President of WA Technology)

This 176 page book includes detailed metallurgical

information about welding Chrome-Moly

CLICK for Book Details |

|

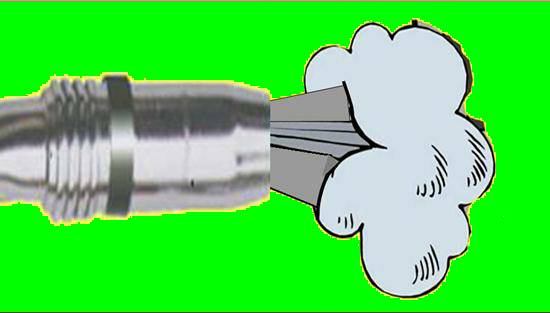

The

"Gas Blast" at MIG Weld Starts Causes Problems: The

"Gas Blast" at MIG Weld Starts Causes Problems:

1)

Shielding Gas Waste

- typically 50% of gas used

2) Inferior Weld Quality

- due to air pulled in gas stream

See Patented

Gas Saver System (GSS)

Solution

GSS

Works for TIG Welders with Foot Pedal or Thumb Control

|

|

This Page Presents Technical Details of Welding 4130

for Other Information:

Click for BASIC 4130 WELDING

DETAILS

Click for

EQUATIONS

defining weld cooling rate in tubing

Click for

WELDING HEAT TREATED 4130 CHROME MOLY

Click for

METALLURGICAL DEFINITIONS

Click for WELDING A BETTER

STEEL; HY 130 |

Stop

Wasting Shielding Gas!! Stop

Wasting Shielding Gas!!

See YouTube Videos

Including Our Patented MIG Shielding

"Gas

Saver System" (GSS)

Why MIG Gas Waste

Detailed Review of GSS

Short Overview of GSS-90 Seconds

What User Say About

GSS

Welding Race Cars

Rat Rods-Then and Now

Welding: Go Green

Engineering A

Pro Street / Street Rod

|

|

MIG Gas Delivery and the Small Block Chevy

Evolved in a Similar Way and Time!

Both had Advances and

Setbacks Before

They Were Optimized!

Click

for a PDF Report on the Similarities |

|

Thanks to those "Car Crazy" folks who have purchased

the Gas Saver System and commented on the improved starts and reduced gas usage

they have achieved. Many purchased our 6 foot prefitted

GSS,

Part Number WAT FB6,

a 3 and 4 foot system, FB3 & FB4, are also available.

ONE PAGE SUMMARY

PURCHASE

GSS PRODUCT

FREE Corvette Accessory Installation Info

|

"WARNING: "Weld

Safely"

|