Welding Carbon Steel Chassis for NASCAR

etc.

By

JERRY UTTRACHI

Race cars require hundreds of

welds. Most welds join intersecting tubes that make up the frame and the all-

important roll cage. NASCAR chassis are unique in racing circles. The cars have

a minimum weight of 1542 kg (3400 lb), quite heavy by race car standards. NASCAR

requires the frame and roll cage components be fabricated from mild steel. This

allows the car to absorb the forces of a crash in a bend-before-break mode.

Although the driver cannot be protected from every incident, considering the

number of high-speed crashes encountered in NASCAR races, the drivers most often

walk away unhurt. This is a tribute to the chassis design and the weld quality.

Race cars require hundreds of

welds. Most welds join intersecting tubes that make up the frame and the all-

important roll cage. NASCAR chassis are unique in racing circles. The cars have

a minimum weight of 1542 kg (3400 lb), quite heavy by race car standards. NASCAR

requires the frame and roll cage components be fabricated from mild steel. This

allows the car to absorb the forces of a crash in a bend-before-break mode.

Although the driver cannot be protected from every incident, considering the

number of high-speed crashes encountered in NASCAR races, the drivers most often

walk away unhurt. This is a tribute to the chassis design and the weld quality.

In addition to the main chassis members,

some welds are made in 4130 chrome moly (molybdenum) tubing used for such things

as radiator supports. Suspension and steering components must also be welded.

Using the proper welding process and filler metals is very important to ensure

superior quality.

ESAB Welding and Cutting

Products, Florence, S.C., recently provided welding training to Petty

Enterprises at its Level Cross, S.C., facility. Below are some key points Bob

Bitzky (shown in photo), an ESAB welding engineer with 25 years of experience in

the welding industry, outlined for the team fabricators.

ESAB Welding and Cutting

Products, Florence, S.C., recently provided welding training to Petty

Enterprises at its Level Cross, S.C., facility. Below are some key points Bob

Bitzky (shown in photo), an ESAB welding engineer with 25 years of experience in

the welding industry, outlined for the team fabricators.

Pick the Process

The first consideration for mild steel welding, which is the predominant

material joined, is deciding what welding process to use. Shielded metal arc (SMAW,

also know as "Stick Welding"), gas tungsten arc (GTAW; also known as TIG or

HeliarcR, or gas metal arc (GMAW; also known as

MIG) welding are the three processes usually considered. Shielded metal arc

welding offers few benefits for in-shop use. The process presents slag removal

and possible slag entrapment issues. Gas tungsten arc welding can produce

excellent quality welds but so can gas metal arc welding. For the majority of

the fillet welds required, GMAW welding is faster and may produce less heat input

for lower distortion. This process also makes it easier to produce

consistent-quality welds. There is a misconception in the race car and street

rod circles that GMAW welding is not usable for critical welds. In fact, the GMAW

process is used extensively in industry to make very high-quality, critical

welds in items such as submarine hulls. Submarine hulls are made from

high-strength steel and are predominantly welded with the GMAW process. Pulsed

gas metal arc welding (GMAW-P) can provide welds without any spatter, similar to

GTA welding, as well as a controllable, hot arc to ensure the weld is fused to

the base metal. Short circuit GMAW welding (GMAW-S) is most often used on thinner

materials such as tubing and provides excellent quality in the hands of a

skilled welder.

Select the Proper

Filler Metals

Selecting the proper filler metal requires an understanding of the mechanical

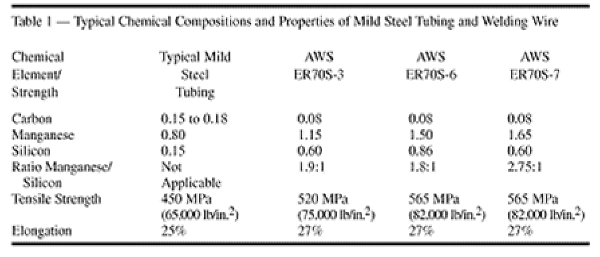

properties desired and weld appearance considerations. Table 1 presents the

chemical composition of typical mild steel tubing and several welding wires that

can be used to join it.

As seen in the table, to achieve the

required strength, welding wires contain less carbon than the base material and

more of the alloying elements, manganese and silicon. These differences, and low

levels of impurities in the welding wire, help provide crack-free and

porosity-free welds. Note that the manganese-to-silicon ratio in ER70S-7 is

significantly higher than ER70S-3 or ER70S-6. This higher ratio gives weld bead

wetting and makes it easier to produce undercut-free welds. ER 70S-7 is the

preferred alloy for welding mild steel. As noted, in general, the welds will be

at least as strong as the mild steel tubing.

Maintaining Welding Parameters

After selecting the welding process and filler metal, the proper welding

parameters must be maintained. Wire feed speed, voltage, and travel speed are

the key parameters to set and maintain. Welding current is a dependent variable

and is controlled by wire feed speed and electrode extension. This extension is

a critical variable. This is the distance from the end of the welding gun

contact tip to the workpiece. In tight confines, it may be desirable to use a

longer contact tip to ensure this value does not exceed about 1/2 in. If the

electrode extension becomes excessive, welding current will automatically

reduce, resulting in a colder weld with reduced penetration into the base metal.

It is important to keep the arc on

the leading edge

of the weld pool to assure proper tie-in to the base material.

the leading edge

of the weld pool to assure proper tie-in to the base material.

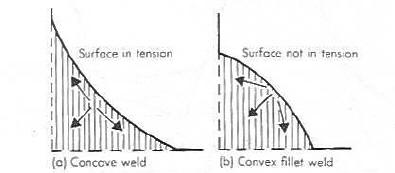

[Although not as common when welding mild steel race car

chassis, making too small and too concave

fillet welds can create problems. This is especially true when using the

TIG (or GTA) welding process. CLICK HERE to see the information and

explanation of this picture in "Welding 4130" .]

Special Cases

Problems encountered can often be fixed. For example, a small weld made on a

heavy steel part cracked immediately after welding. The cause was attributed to

the very high restraint being placed on the small weld bead. Also, a

high-strength stainless steel alloy was used as the filler metal, which further

stressed the weld joint. The solution was to use a lower strength carbon steel

filler metal and a larger, more convex weld bead.

In another case, a crack occurred when

welding on a small threaded part. A chemical analysis performed on the part

indicated it was made from free-machining steel. This particular alloy used a

high sulfur content to aid the machinability. Some free-machine alloys also use

additions of lead or phosphorous. High sulfur, phosphorous, or lead additions

can only lead to poor quality welds. The solution for this application is simply

to not weld free-machining steels. The machine shop should pick another alloy.

Summary

Selecting the proper process is the first task of ensuring quality welds. Gas

metal arc welding can be used very effectively to achieve the desired results.

Picking the proper filler metal is also critical. An AWS ER70S-7 welding wire is

a good choice for welding mild steel.

For GMAW, selecting and

maintaining the proper welding voltage, wire feed speed, and electrode extension

are very important to achieving quality welds. The resulting welds should be

checked and verified to be sure they meet the requirements. As a minimum, all

should be checked and verified to be sure they meet the requirements. As a

minimum, all welds should be visually inspected for

undercut and smooth transition to base metal. When satisfactory welds are

produced, record the machine settings for future reference.

Closing Advice

Be sure to employ the skills of a qualified

welder. Quality Short Circuiting MIG welding requires keeping the arc in

front of the weld puddle to avoid lack of fusion or what is often referred to as

"Cold Laps." The weld may look OK on top but not be adequately fused to

the base material.

Small 110 volt input MIG welders may not have

sufficient power or the proper arc characteristics to assure quality welds when

making critical joints on material as heavy as structural tubing.

See a Video of Richard Petty and myself discussing

the importance of welding in keeping a driver safe!! Click here or on the move

camera ICON

See a Video of Richard Petty and myself discussing

the importance of welding in keeping a driver safe!! Click here or on the move

camera ICON

What about Welding 4130? (see summary

elsewhere on this web site)