| Holley Double Pumper in Car

See Video

" Tuning Holley Carb"

|

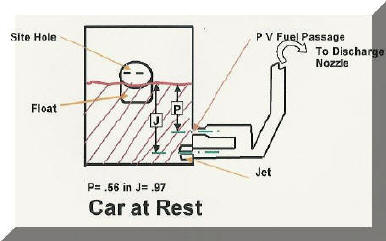

Once it was realized, by using an

Air/fuel meter, the problems with the Vacuum

Secondary Carb could be quantified, the solutions became obvious. One

confusion was the method given in several references on how to adjust

the Jet Size and Power Valve fuel passage size. It was indicated if

the Jet size is reduced significantly the Power Valve fuel passages could be

drilled out to compensate. |

| It was advised to increase the diameter to

equal the area lost with the Jet size reduction. However this did not

work and provided an excessively rich mixture. Looking at the geometry

of the system it is obvious the Power Valve fuel passages are

significantly higher in the fuel bowl (See distance P in the schematic of

rear fuel bowl "Car at Rest" below) and therefore would not flow as much

fuel for a given size as the Jets (J in schematic). Rather it would

be more proportional to the fuel head ratio (distance from fuel level to

gas passage) as well as the area. This comes much closer to what

should be done and what resulted in the optimum settings. |

| Calculate Jet Size to Compensate for Blocked Power

Valve The deviation caused by the physically higher Power Valve fuel passage is

most dramatic when calculating the needed Jet size increase when the Power Valve

is blocked on the Secondary. If one used the methods proposed in the most

references, for the 850 Double Pumper the calculations would be:

-

The original Power Valve fuel passages were .067 inches. Since there

are two power valve passages and two jets we will calculate on the basis of

one pair. The area for a .067 inch passage is .0035 square inches.

-

The number 80 Jets which came on the Carb are .093 inch diameter or .0068

square inches

-

The total area would be .0068 + .0035 or .0103 square inches

-

This equates to a diameter of .114 inches which is a # 94 or 95 Jet

(tables available in references provided).

On the other hand, to compensate for the differences in fuel head in the

secondary float chamber you modify the Power Valve area by the ratio of

the fuel head heights. Namely 0.97 inches (J in above schematic) from the fuel level to the center line

of the Jet passage versus .56 inches (P in above schematic) from the fuel level to the centerline of

the Power Valve fuel passage. Or .56/.97 = .58 or :

-

The Power Valve effective area would be .0035, as above, times .58 or .002

square inches

-

Adding this to the .0068 inches as noted above gives a total effective

area of .0088 square inches which calculates to a diameter for the new Jet of

.108 inches. This is a Jet size of # 88 versus the previous calculation

of # 94 to 95. It fact this is the one which worked!

|

|

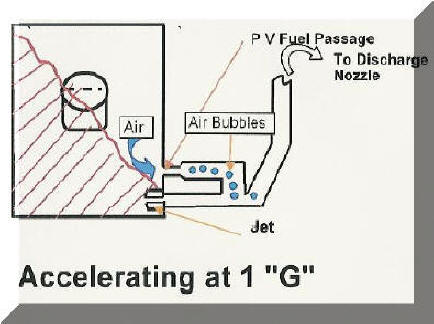

Fuel Level When Accelerating

The schematic above depicts the fuel level when the car

accelerates at 1"G". Effectively it is like the car being tilted up at a

45 degree angle with a 1"G" force acting downward on the fuel due to gravity and

another 1 "G" rearward due to acceleration. Note the higher Power Valve

fuel passages would be exposed to air not fuel.

|

| In fact the jets themselves are at risk of

being exposed to the air. (That's one reason Pro Stock Drag cars mount

the carbs sideways!) To correct this problem two steps are taken.

First the Power Valve Fuel Passages are blocked with a plug (see photo far

left below) .

Want to measure the variations in fuel

level? Check out this new device. |

|

|

|

|

| Second the jets (larger ones to compensate for the blocked power valve

passages) are moved with an extension (see above center left photo) that places them

in the rear of the bowl where they can not be uncovered even with 2 "G's" or

greater acceleration. Jet extensions require a special "notched float"

(photo center right) to provide the proper clearance. You can purchase

these two items as a set. Since we're on the subject of rear bowl modifications,

the photo to the far right above is an internal Bowl Vent Extension (also called

a 'Whistle") that

prevents fuel pushing forward into the vent which exits at the top on the bowl

into the carburetor when abruptly stopping. This can cause flooding.

It should be added as well. |

|

Accelerator Pump

Even with the proper jets, a lean bog would occur when the Secondary butterflies

were instantly opened when

accelerating. The normal fuel delivery system could not provide enough

fuel in time. The accelerator pump circuit

supplies added fuel to match the increased air flow that occurs instantly.

It was found that a 50 cc front pump improved the response over the 30 cc pump

which came with the carburetor (see the larger 50 cc versus 30 cc pump diaphragm

on left photo below). Optimizing the Squirter size and Cam took trial and error (right in

photo below). When installing the larger "Squirters" use a higher capacity

"Squirter Screw" (photo far right below). A Yellow Cam is used on the Primary and a Brown Cam (quick

fuel shot but does not completely empty the accelerator pump reservoir) on the

Secondary. A Holley Representative I talked with at the Rockingham Drag

Racing track was a help with suggestions as well.

|

|

|

|

| These modifications solve the problems of acceleration and deceleration. In a

light Street Rod, blocking the Power Valve and using larger Secondary Jets has little effect on fuel mileage since the

Secondary

with their progressive linkage are

seldom brought into play when cursing or in any normal driving. However

when needed there is all the power desired, immediately! |

|

A

subtle but important tuning item are the accelerator pump cams. With

the 50CC pumps I found the brown cam was best for the rear bowl. It

gives a quick shot of fuel but does not empty all the fuel in the reservoir. A

subtle but important tuning item are the accelerator pump cams. With

the 50CC pumps I found the brown cam was best for the rear bowl. It

gives a quick shot of fuel but does not empty all the fuel in the reservoir.

Used a yellow cam

pump for the front bowl. They come as a set for under $25.

You'll need some trial and tests to get the proper ones for the car weight,

axle ratio, tire grip and acceleration achieved.

This is what

Holley says about them: "Holley accelerator pump cams will allow you to

"tailor" accelerator pump performance to the engine's actual requirements.

They include cams that have a different shape or profile to give different

results. Cam "lift" directly affects the accelerator pump stroke, and,

therefore, pump capacity. Ramp profile or shape controls the "timing" of the

shot. A steeply-rising ramp shape will give a fast, heavy fuel shot right

off idle. Conversely, a gently sloping ramp will spread the pump action over

a longer period of time." |

|

Other Modifications

A few other modifications are worth mentioning. An

electric choke kit was added to the Double Pumper which comes with a manual

choke. A choke is needed to assist starting and the electric one works

fine with no need for a cable. One caution. With the two 50 cc pumps

DO NOT put your foot to the floor when starting or you'll be changing wet plugs!

A 1/4 depression of the accelerator peddle is all that is needed!

(Leaving a car show late last year when it was cool at night, I mistakenly gave

it almost 1 full pump!! It missed all 10 miles home! Next morning I pulled

the plugs and sure enough one had obviously not fired. Simply cleaned them

and all was fine. Even after starting for this years "season" and

carefully depressing only 1/4 throttle, it started fine!)

The Double Pumper does not come with bronze fuel filters.

I thought since I use a K&N stainless filter (left photo below) before the blue

Holley high capacity electric fuel pump and another in line after the pressure

reducing regulator that would be OK. I found that I occasionally got some

flooding when decelerating after a quick hard run. Again the Holley folks

thought it might be a high fuel level ( which after checking it was not) or

dumping fuel into the Carb from the bowl vent so I added higher vent tubes but

the problem remained. They then thought it was a sticky fuel pressure

regulator. Since I had another I swapped it with no improvement (pressure

set at 7 psi).

This problem had not existed with the Vacuum

Secondary Carb,

|

|

|

I deduced one difference was the lack of bronze fuel filters (right photo above) in

the Double Pumper Carb. These do create a small pressure drop and help avoid an

instant rush of fuel past the large fuel inlet needle valves after the bowls are low on a rapid acceleration "Banzai Run". I

installed them and that has solved the problem! The car has been running

fine for over three years without one instance of flooding (accept as mentioned

above when I used "I Know Better" procedure! |

An

interesting article in the July 2005 issue of "Hot Rod" Magazine describes a

new product that provides an explanation for the filter working!

Check it out! |