The Following is a Summary of the Article in the

AWS Journal

"GMAW

SHIELDING GAS FLOW CONTROL SYSTEMS"

An article was published in the American

Welding Society's (AWS) April Welding Journal (page 22) with the above

title.

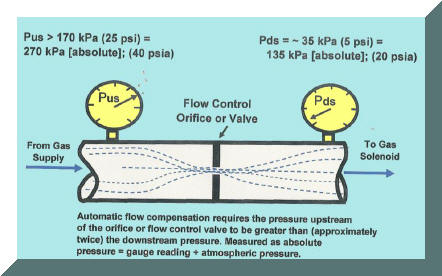

It defined what

"Automatic

Gas Flow Control was all about. As stated, the pressure upstream of

the flow control must be a minimum of 25 psi to have this feature.

That is why MIG welding gas supply systems have been set at this pressure or

higher from the inception of MIG welding. Recently some "low pressure"

devices have been introduced in attempt to solve shielding gas waste due to

starting surge. These systems do not maintain flow. As stated in

the article variations in flow of up to 65% were measured with such systems.

It also suggests ways are available to retain "Automatic Flow Control" while

reducing shielding gas waste.

"Automatic

Gas Flow Control was all about. As stated, the pressure upstream of

the flow control must be a minimum of 25 psi to have this feature.

That is why MIG welding gas supply systems have been set at this pressure or

higher from the inception of MIG welding. Recently some "low pressure"

devices have been introduced in attempt to solve shielding gas waste due to

starting surge. These systems do not maintain flow. As stated in

the article variations in flow of up to 65% were measured with such systems.

It also suggests ways are available to retain "Automatic Flow Control" while

reducing shielding gas waste.

Click on the photo above for a Link to

the AWS article.

CLICK HERE

to see the actual flow test results of standard systems compared to a

commercially sold "low pressure system that mounts at the feeder.