|

Guess I Built

What You Could Call A

Rat Rod!

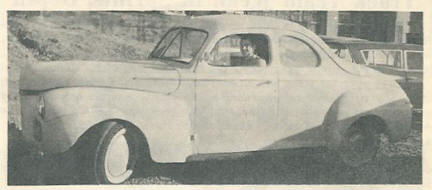

There

are a number of what are called "Rat Rods" showing up at car shows. My ’34

Street Rod is not one, however when looking at these cars, some remind me

of what I built as a teenager! We didn't call them "Rat Rods" but when

I recall the gray primer, unfinished engine compartment and many home made

parts, guess you could call it that! That's me in my 50's "Rat Rod."

The following are details of the car: There

are a number of what are called "Rat Rods" showing up at car shows. My ’34

Street Rod is not one, however when looking at these cars, some remind me

of what I built as a teenager! We didn't call them "Rat Rods" but when

I recall the gray primer, unfinished engine compartment and many home made

parts, guess you could call it that! That's me in my 50's "Rat Rod."

The following are details of the car:

|

|

Those Were The Days

In my early teens I was influenced by

two neighbors cars (well actually three.) The fellow directly across the

street was probably 5 years older than I and bought a 1950 Merc with a

chopped top. It was reportedly chopped by George

Barris

on the West Coast. I thought it was super cool and would look thorough the

garage window to see what he was doing to it. (Pic on left is not his but is

very similar. I remember those two teardrop spot lights and "frenched headlights")

I recall him telling me it was a real "lead sled" with lead cracking

in a number of spots! When he and his car club friends started to repair the “cracks”

one told me all the contours had so much lead that it was going to be

difficult to repair! They were going to remove the

lead and try to use mostly hammered sheet metal. Not sure how much they

accomplished. Barris

on the West Coast. I thought it was super cool and would look thorough the

garage window to see what he was doing to it. (Pic on left is not his but is

very similar. I remember those two teardrop spot lights and "frenched headlights")

I recall him telling me it was a real "lead sled" with lead cracking

in a number of spots! When he and his car club friends started to repair the “cracks”

one told me all the contours had so much lead that it was going to be

difficult to repair! They were going to remove the

lead and try to use mostly hammered sheet metal. Not sure how much they

accomplished.

I also recall that NJ Auto Inspection was very critical of his small windshield

height and would not allow the electric doors with a hidden button used to activate the solenoid that operated the latch!

They claimed “in case of emergency" the

police could not get in!! (Wonder how they feel about my new Vette which has

electric doors!!) He must have gotten past the windshield height but

had to make what were very creative door handles!  They installed a

round button in a curved recess they formed in the door for a handhold. It provided

the leverage to push the button with your thumb and pull the door open (schematic right).

I've always looked for something similar at car shows but have never seen

anything so neat. Guess we're all using electric doors and not

worrying about the emergency responders! They installed a

round button in a curved recess they formed in the door for a handhold. It provided

the leverage to push the button with your thumb and pull the door open (schematic right).

I've always looked for something similar at car shows but have never seen

anything so neat. Guess we're all using electric doors and not

worrying about the emergency responders!

Living next door to my ’50 Merc neighbor were

twins. They were pr obably

10 years older than I so only knew them to say hello and look at their

cars. It was the mid 50’s and they just returned home from the Korean War. When

they came home they purchased two matching green 100-4 Austin Healeys! Even I

knew than the 90 HP 4 cylinder was not a lot of power, but they were so light,

they were pretty fast and they looked

so cool! Guess between the two (or three) cars it set the tone for the cars I

wanted, at least my long term desires. obably

10 years older than I so only knew them to say hello and look at their

cars. It was the mid 50’s and they just returned home from the Korean War. When

they came home they purchased two matching green 100-4 Austin Healeys! Even I

knew than the 90 HP 4 cylinder was not a lot of power, but they were so light,

they were pretty fast and they looked

so cool! Guess between the two (or three) cars it set the tone for the cars I

wanted, at least my long term desires.

|

|

The ‘41

In NJ you could get your license at 17. I was

working in a supermarket since I was 15 ½ so I had saved some money to buy a car

when I was 16 ½, which I did! Wanted one before I got my license. Pop wasn’t very happy

with the idea but it was my money. Looked around for a '40 Ford Coupe.

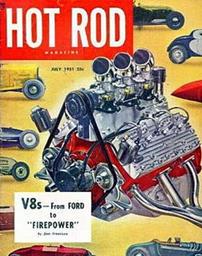

Being an avid reader of Hot Rod, Car Craft and some of the other smaller size magazines made

me think the’40 was just what I wanted. However there were very few to be had. There was

a '40 Merc convertible for sale but I didn’t like its looks. Never did like

convertibles and never owned one (accept for my CJ5, but that’s different.)

A

classmate had a '41 Ford opera coupe he talked to me about and was willing to

sell. I went to look at it and although I d A

classmate had a '41 Ford opera coupe he talked to me about and was willing to

sell. I went to look at it and although I d didn't

like it as much as a ’40 it was an Opera Coupe and looked cool. It had a '50

Merc flathead with dual exhausts and the interior had been redone in Naugahyde (that was the

trade name for Vinyl!) It wasn’t the rolled and pleated trendy

treatment of the day

but it was well done. The car also ran and had no rust. There were some

things I needed to do and I had about 6 months before my license so there was

time. I was a Junior in High School and I attribute building the car

as being a big help

getting into College to obtain Engineering degrees. Between working on the car and working

in the supermarket to pay for all

the extra’s I wanted there was not a lot of time to get

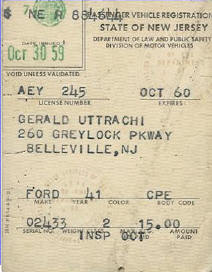

in trouble. Well mostly! That's me on the right and the '41

coupe registration left. didn't

like it as much as a ’40 it was an Opera Coupe and looked cool. It had a '50

Merc flathead with dual exhausts and the interior had been redone in Naugahyde (that was the

trade name for Vinyl!) It wasn’t the rolled and pleated trendy

treatment of the day

but it was well done. The car also ran and had no rust. There were some

things I needed to do and I had about 6 months before my license so there was

time. I was a Junior in High School and I attribute building the car

as being a big help

getting into College to obtain Engineering degrees. Between working on the car and working

in the supermarket to pay for all

the extra’s I wanted there was not a lot of time to get

in trouble. Well mostly! That's me on the right and the '41

coupe registration left.

One of the first projects was to define

what to do with the rear seat, or lack there of. As mentioned, the front

seat was reupholstered in vinyl, green and white. The dash was painted white

and looked good. But there were no seats, or upholstery in the rear! It was an Opera

Coupe which meant it should have had two seats that attach to the rear

sides and hinged down. But there was nothing back there! Nothing on the sides or back, you

could see through to the trunk! Just a rear metal brace. What to do?

Decided no one was going to sit back there so why not just put a Tonneau

Cover in the rear! Made a wooden frame from some 1 X 4

scrap wood. The

4 inch side faced up. It was flat on top and joined in the corners

with "corrugated nails" (photo left - not sure why I remember such trivia!) Shaped the rear of the

frame to fit

the curved interior headliner which extended below the rear window. Attached it with bolts hidden under the

vinyl covering to three “L” brackets that were

screwed into the metal side posts and the rear metal "X" brace. Attached it from

underneath to the bolts with wing nuts. To cover the wood it needed some padding scrap wood. The

4 inch side faced up. It was flat on top and joined in the corners

with "corrugated nails" (photo left - not sure why I remember such trivia!) Shaped the rear of the

frame to fit

the curved interior headliner which extended below the rear window. Attached it with bolts hidden under the

vinyl covering to three “L” brackets that were

screwed into the metal side posts and the rear metal "X" brace. Attached it from

underneath to the bolts with wing nuts. To cover the wood it needed some padding before stretching white Naugahyde over the frame. Foam was

readily available at the time and money was always an issue. Found some

great material that acted like foam. A scrap Chenille bedspread (that's

Chenille fabric right!) The little “knobs” in the material made a good

cushion! Put a couple of layers together and stapled it to the wood frame.

Stretched the white vinyl over the padded frame and stapled it to the

underside. The Tonneau covered the whole rear section of the car flush with the top of the front seat. Looked great! The only other thing to do on the interior was to

make the dash look custom. The A and B interior pillars, window frames and

dash were painted white which looked OK but needed some “Green” to match the

two tone seats. Decided to put some green highlights on the edges so masked

off all the parts not to be painted and use a quick spray for a

mist of green but not a solid color. I thought it

before stretching white Naugahyde over the frame. Foam was

readily available at the time and money was always an issue. Found some

great material that acted like foam. A scrap Chenille bedspread (that's

Chenille fabric right!) The little “knobs” in the material made a good

cushion! Put a couple of layers together and stapled it to the wood frame.

Stretched the white vinyl over the padded frame and stapled it to the

underside. The Tonneau covered the whole rear section of the car flush with the top of the front seat. Looked great! The only other thing to do on the interior was to

make the dash look custom. The A and B interior pillars, window frames and

dash were painted white which looked OK but needed some “Green” to match the

two tone seats. Decided to put some green highlights on the edges so masked

off all the parts not to be painted and use a quick spray for a

mist of green but not a solid color. I thought it

looked

good! Now for some green knobs. The "In Thing" at the time were

laminated plastic teardrop knobs. Found the pics on the left on the Internet

showing how

they are made! The ones I purchased were probably also hand made. They

were pretty expensive considering my small budget. Mine of course were green and white. Photos shows

how the pieces were laminated than ground and polished. looked

good! Now for some green knobs. The "In Thing" at the time were

laminated plastic teardrop knobs. Found the pics on the left on the Internet

showing how

they are made! The ones I purchased were probably also hand made. They

were pretty expensive considering my small budget. Mine of course were green and white. Photos shows

how the pieces were laminated than ground and polished.

Now for the exterior. Couldn’t

absorb all the material in “Car Books" and not want the "clean look" popular at the time. It was

off with the parking lights that were on top of the fenders (NJ Inspection

would have to live with the truck amber clearance lights purchased at Pep

Boys and installed in the side grill openings (the side grills were missing.)

Had to remove the hood and trunk chrome and handle. The holes left in the

trunk and fenders were no problem using fiberglass, or so it said in the “How To Do” articles

in the car books. Considered one of the electric solenoid kits from JC

Whitney to open the truck but a modified junk yard choke cable operated from

under the rear Tonneau fit the budget and worked! Spent a lot of time

in junk yards for the project!

Pop was a very good mechanic, not what he

did for a living but for an amateur he would tackle anything. I would help

with brake jobs, oil changes, wheel bearings etc. Uncle Fred

managed a Chevy Service Department, so we could get special tools and advice

when needed - more about Uncle Fred later. However Pop nor Uncle were

body men, so had no experience with the “fiberglass” the articles said was

easy to use! Well I did learn to use it! I learned excess

hardener meant it set too fast and not enough meant in didn’t harden and had

to be removed. Messy and difficult to do! Also learned a heat lamp

was needed when it was cold and to get ready for lots of

sanding." The detached garage where I

worked had no heat. If they had Bondo in the

mid 50’s I didn’t know about it or it was too expensive! I used a technique

found in one of those “You Can Do It" articles. I cut the glass cloth into

very small strands with scissors and mixed it with the two part polyester resin and the glass flour you could buy to make a paste.

Applied quickly it was good for the next major project, the front grill.

The car had a center grill but it had a big dent.

Looked to purchase one from the “junk yard” but there were no ’41 Fords

in the meadow lands junk yards that I mostly visited. These are no

longer in NJ, they have built up the area with things like Giant Stadium! They were

also next to the garbage dump for most of Northern New Jersey. They

would get cars in and put one on top of the other. Great for some

parts but not ’41 Fords. In any case must have seen a '40 or ’41 with a

filled center grill in one of the magazines so thought that would be a

"cool" solution (actually tuned out not to be so "cool," more like a "warm"

idea!) Got some heavy sheet metal and cut it with tin snips so it would fit over the

grill. Used the bolts fastening the grill to the fenders and inserted

tabs made in the sheet metal to secure the “grill cover.” I recall

having to use quite a bit of force to bend it in shape but it looked good

accept the edges needed to be faired into the fenders. Did that with

fiberglass tape and my mixture of cut glass, glass flour and resin. Worked fine and didn’t

crack!

"Nosing" the hood was another task. Pop had a

friend with a body shop not to far from the house. (He was very helpful for a

number of projects such as attaching the exhaust on the Olds engine to the

dual exhausts.) As I recall, one of those magazine articles said the

two piece hood would crack with just fiberglass holding it together and recommended

welding first. Took the hood to dad’s body shop f riend. He brazed

some 1 inch long tacks along the seam using a wet rag to reduce distortion. Took the hood home and

layered on strips of fiberglass cloth to create a smooth “nosed” hood. Lots

more sanding. Only one thing left, the taillights. Don’t know why, but

didn’t like the ‘41 taillights (photo left.) Guess had to have something "custom." An ‘in” approach was to use '51 riend. He brazed

some 1 inch long tacks along the seam using a wet rag to reduce distortion. Took the hood home and

layered on strips of fiberglass cloth to create a smooth “nosed” hood. Lots

more sanding. Only one thing left, the taillights. Don’t know why, but

didn’t like the ‘41 taillights (photo left.) Guess had to have something "custom." An ‘in” approach was to use '51  Buick taillights. Looked easy, just get a pair from the junk yard. Junk yards at the time, or at least the ones I visited in the

Kearny Meadows, didn’t strip anything like taillights. In fact most of the

cars were sold for scrape after folks stripped major items. You might

have to climb up on a car to get at them but for a few bucks

I got the Buick taillights. Photo right is what they looked like on a 51

Buick. Looked easy, all I had to do was grind down the back of

the bezels to match the contour of the Ford fender. I recall it was a

study in geometry, easer said than done. But after a lot of trial

fitting and grinding they looked fine.

Buick taillights. Looked easy, just get a pair from the junk yard. Junk yards at the time, or at least the ones I visited in the

Kearny Meadows, didn’t strip anything like taillights. In fact most of the

cars were sold for scrape after folks stripped major items. You might

have to climb up on a car to get at them but for a few bucks

I got the Buick taillights. Photo right is what they looked like on a 51

Buick. Looked easy, all I had to do was grind down the back of

the bezels to match the contour of the Ford fender. I recall it was a

study in geometry, easer said than done. But after a lot of trial

fitting and grinding they looked fine.

Since the trunk trim was removed, needed a

place for the license plate. Attached a home made holder below the rear bumper.

Made a license plate light from some ¾ inch copper tubing which I slit and

installed a light bulb socket. The light was hidden by the rear

bumper. I remember the design since I was stopped

by the police for not having a license plate light and when I went back to

the rear and touched it went back on! Got out of a ticket with, “You’d

better fix that!”

The last thing needed was paint.

Talked about getting the car painted but primer was

fine for now and all I could afford! Pep Boys had a thick primer,

guess we’d call it primer surfacer today. One coat was all that was

needed. How to apply? Pop let me use one of his very special

"natural hair" 4 inch brushes!! Looked fine!

Guess I used a smaller brush around the windows since I recall the overall

job was very neat. Couldn't

see the brush strokes! We did have some neat paint jobs available at the time and shops that

could apply candy apple colors etc. Flames and pin striping were “in”

and at car shows you could see the latest craft. But for my daily

driver, primer was fine and fit the budget. Never did paint it!

|

|

The Engine

(First One)

The car came with a 50 Merc engine. No

that's not a picture of my flathead on

the left but sure wanted those three

two's. The car came with a 4:11 rear end ratio so it felt pretty

fast, at least in the driveway which, without a license, was where I drove! . That was

one of the stock ratios with

Ford. Had a friend who had “hopped up” his 1950 Merc. It was nosed

and decked, neat paint and the engine had two - two barrel carbs and

aluminum heads. However it wasn’t very fast. Couldn’t beat my other friend with a 54

Pontiac! I didn’t want my "hot rod" to be slow so found someone selling a three

two barrel aluminum manifold with three Stromberg 97’s. The magazines said

that was the “ticket!” It was summer; I was out of school and was still

working in the supermarket at the end of the week at nights and on

Saturdays. Left a lot of time so why not "port and relieve" this engine!

Porting was not a big deal in a flathead as the passages are short. But

needed to get the gas in and out of the valves to the piston area. That meant

"relieving" the block, as it was called. This was especially needed with the thin copper gaskets I was

going to use to increase compression. Using thin head gaskets was as far as I

was going since by friend with the 50 Merc had just blown 3 spark plugs out

of his aluminum heads after putting too much ether in his tank! That was a

trick we used when we had a "money race." Not sure how much it helped but you

could buy cans at the drug sto the left but sure wanted those three

two's. The car came with a 4:11 rear end ratio so it felt pretty

fast, at least in the driveway which, without a license, was where I drove! . That was

one of the stock ratios with

Ford. Had a friend who had “hopped up” his 1950 Merc. It was nosed

and decked, neat paint and the engine had two - two barrel carbs and

aluminum heads. However it wasn’t very fast. Couldn’t beat my other friend with a 54

Pontiac! I didn’t want my "hot rod" to be slow so found someone selling a three

two barrel aluminum manifold with three Stromberg 97’s. The magazines said

that was the “ticket!” It was summer; I was out of school and was still

working in the supermarket at the end of the week at nights and on

Saturdays. Left a lot of time so why not "port and relieve" this engine!

Porting was not a big deal in a flathead as the passages are short. But

needed to get the gas in and out of the valves to the piston area. That meant

"relieving" the block, as it was called. This was especially needed with the thin copper gaskets I was

going to use to increase compression. Using thin head gaskets was as far as I

was going since by friend with the 50 Merc had just blown 3 spark plugs out

of his aluminum heads after putting too much ether in his tank! That was a

trick we used when we had a "money race." Not sure how much it helped but you

could buy cans at the drug sto re

and it was a common thing to do. Guess it did something since it caused his

plugs to strip out of the aluminum heads and dent his hood!! re

and it was a common thing to do. Guess it did something since it caused his

plugs to strip out of the aluminum heads and dent his hood!!

Relieving looked easy,

just get some grinding wheels and grind down the passage from each valve to

the cylinder. Photo left shows a stock flathead block with stock vale

pockets. The photo below right shows the grinding that was done to

"relieve" the passage from the intake and to the exhaust valve so gases had

an easier time making the trip! Went to the local hardware store which was

within walking distance and purchased some grinding wheels that fit my

drill. I remember vividly they had a small bucket on the counter of various shapes

all with shafts attached. I remember it vividly because after about two

weeks of waking there about every day I had purchased most of them!! They were not the thing to use on cast

iron. But the job was done. Now I would drive up and down the driveway.

Had the hood off since I had been standing inside the engine compartment

with my drill and grinding wheels! Lucky it had no hood since that three carb set-up liked to

backfire! With no air cleaners, flames would shoot out of all three carbs! I blamed the carbs!! I went to the auto parts store where I always

got a mechanic’s discount because of Uncle Fred! I recall asking if I could

trade in the 97’s and get rebuilt 94 carbs. The fellow at the counter, who I

knew said, "no way - those are ancient!" I informed him these were the best carbs you could buy (said that in all the magazines!) He laughed. I was

mad! Fortunately a local drag racer who I had seen at the drag strip

with his blown '34 Ford Gasser (but

didn’t know personally,) said to the fellow behind the counter that he’d give the $5

trade allowance each for these

remember vividly they had a small bucket on the counter of various shapes

all with shafts attached. I remember it vividly because after about two

weeks of waking there about every day I had purchased most of them!! They were not the thing to use on cast

iron. But the job was done. Now I would drive up and down the driveway.

Had the hood off since I had been standing inside the engine compartment

with my drill and grinding wheels! Lucky it had no hood since that three carb set-up liked to

backfire! With no air cleaners, flames would shoot out of all three carbs! I blamed the carbs!! I went to the auto parts store where I always

got a mechanic’s discount because of Uncle Fred! I recall asking if I could

trade in the 97’s and get rebuilt 94 carbs. The fellow at the counter, who I

knew said, "no way - those are ancient!" I informed him these were the best carbs you could buy (said that in all the magazines!) He laughed. I was

mad! Fortunately a local drag racer who I had seen at the drag strip

with his blown '34 Ford Gasser (but

didn’t know personally,) said to the fellow behind the counter that he’d give the $5

trade allowance each for these

carbs (picture left is a Stromberg 97.)

I thanked him and walked away with 3 rebuilt 94’s!

They were better but I was still way over carbureted. Needed progressive

linkage which I bought but when those last two carbs opened I still had much

more air than I could use and the car would go lean. Needless to say I

wasn’t pleased that even if I got this corrected I was going to be very

fast. carbs (picture left is a Stromberg 97.)

I thanked him and walked away with 3 rebuilt 94’s!

They were better but I was still way over carbureted. Needed progressive

linkage which I bought but when those last two carbs opened I still had much

more air than I could use and the car would go lean. Needless to say I

wasn’t pleased that even if I got this corrected I was going to be very

fast.

I got my license the first month of

school. Driving the car I realized it burned quite a bit of oil! I wasn’t

worried about the cost but the smoke coming from the tail pipes was embarrassing!!

Knew an engine rebuild was in order and the car just wasn’t very fast. Why put

more good money and not accomplish the "go fast" objective.

|

|

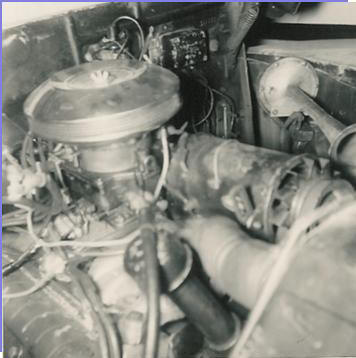

The Olds Engine

By luck, a friend said he had a

50 Olds engine in pieces in his garage! I knew it would have much more

power than the flathead. For a few bucks I bought the parts

hoping they were all there! A true basket case! It

came with a transmission adapter from the Olds engine to the '41 3 speed trans, a 3/8 inch thick plate with the

appropriate holes matching both pieces. My friends helped get the block in my basement.

The

pistons, rods, crank main caps, timing chain and all other parts (I hoped,)

were in a big wood peach basket! Before I spent time and money on the

Olds engine I wanted to be sure it wasn’t going to burn oil! I wasn’t going

to have a "smoker" again! (Picture at left is the only one I

have from that time. It is the Olds in the '41. Performance, not

appearance was my first goal! The

pistons, rods, crank main caps, timing chain and all other parts (I hoped,)

were in a big wood peach basket! Before I spent time and money on the

Olds engine I wanted to be sure it wasn’t going to burn oil! I wasn’t going

to have a "smoker" again! (Picture at left is the only one I

have from that time. It is the Olds in the '41. Performance, not

appearance was my first goal!

The auto parts store I dealt

with also had a machine

shop. They sent someone over to measure the size, taper and roundness

of the cylinder walls. As I watched him make the measurements he said;

"it’s borderline, it may be OK! "Maybe and OK" were not what I wanted

to hear! However, I paid very little for the engine so why not have it

bored out! An article in Hot Rod said you could bore a ’50 Olds block

1/8 inches and use ’55 Olds pistons. Sounded good to me, it would then

have 324 cubic inches versus the 303 in the '50. That was more than

the 265 and the new 283 Chevy V8 that had just been introduced. In

addition, the Chevy engine was very new and couldn't find those in the junk

yard at a price I could afford. There were no "crate engine" programs at the time and I didn't have the money

if their were!

Went over to

the auto parts house and said "bore it out 1/8 inches I don’t want an oil

burner." They refused, swore they would be in the water jacket. I said,

being a determined young man, "Hot Rod says you can do it!!" I didn’t know

about potential core shift etc at that time. They said; "Take all

responsibility for creating a hole and buy the pistons from

us and we’ll do it." The machine shop had never bored out anything more than a 1/16 inch

before so they charged extra. To bore them out it would be $5.00 a hole

is what I remember.

That was about the same price they charged for each new piston as I recall. A lot of money for me at the time but I said go!

After boiling the block they installed new cam bearings. I bought a

'55 Olds cam from the Olds dealer. The magazines said that was the low cost approach rather than buy an expensive Isky cam.

It had higher lift and duration and retained the hydraulic lifters and non

adjustable rockers. The machine shop also ground

the crank and sold me a rebuild kit, new bearings, gaskets, rings etc.

My friend with the 50 Merc was going to

auto mechanic school and said he would do a valve job on my heads as part of

his classes. Took him a while to finish but when I got them back found

he had polished the chambers and ports. You could see yourself in the

chambers!! Don’t know how much good it did but it sure looked great!

I recall rebuilding the 4 barrel carb

that came in that fruit basket of parts! I did the wok on a

portable coffee table in the

sun parlor. Cleaned all the parts in the basement with gasoline and boy did it smell

up the house! Took a few days but got it all back together following the

instruction sheet that came with the rebuild kit!

I received a phone call from the machine shop

saying two of the rods were stretched and there was a problem with the

thrust

surface on the crankshaft! Fortunately my buddy with the Merc

had a set of 50 Olds rods and a crack. He donated them to the project! I gave

the extra eight rods to the machine shop and asked

them to pick the ones that matched best! They found a good eight

from the 16! His crack was also find for regrinding .

Must

admit it didn’t seam like a problem putting the engine together without a

manual. Today I won’t touch a part without first consulting the service

manual. Everything went together correctly and when I put the bottom end

together I used Plastigage and checked all clearances. I remember the

machine shop had to wait for the pistons so they could mic each and finish

hone the bores to match. They even understood the importance of close

tolerances in the '50's! I recall phoning Uncle Fred and asking him to

drop off a torque wrench on his way home from work. Hot Rod said it was a must. He said.

"that’s not

what you need; you just need a pry bar." Hot Rod couldn’t be wrong and I

wanted this engine to be right. He came over the house with both. He said,

“I’ll pull the bottom end down with the pry bar and you check it with the

torque wrench." Wonder if he was "feeling" the bolt stretch or just from his

past experience was able to tighten up the main bearing caps and rod bolts

without me ever doing more than verify they were all in excess of the torque

since I didn’t get them to budge! I did put the heads on using the wrench

and the proper torque sequence per the articles I read.

Everything but the carburetor was now

together in the basement. Had not considered how much more it would weight

then when the parts were brought down separately!

Put it on a two wheeled hand cart. Took several friends with a rope

pulling and a few pushing and lifting to get the engine up the basement

stairs and out the door!

The flathead was easy to take out of the

Ford with a chain block and tackle. However this Olds was much heavier.

Could tell when we tired to lift it. Even the garage roof beam was

bending and we had to nail some 2X6 boards together to make a temporary

column to brace it! I had purchased some Olds-to-Ford motor

mounts. As mentioned, with the engine parts I purchased was a flat plate adapter to

connect the stock Ford trans to the Olds. There was a pilot bearing adapter that pressed into the flywheel and

extended the hole for the transmission shaft to make up for the 3/8 inch

thick adapter. Another friend lent me a Ford transmission input shaft so I could bolt up the clutch.

Used the clutch that was in the Merc engine. His brother had built a ’28 Ford and offered to move my steering box into the

frame to clear the starter. He had an oxyacetylene cutting and gas

welding outfit. But I elected to buy what was called a "starter

switchover  kit" that moved the starter from the left to right side so it would not

interfere with the steering. It was an

expensive purchase and when I received it I realized I had to cut off a part

of the starter nose to clear the housing. I recall pondering how I would

get this done. Probably kept me up one night! I put a new blade on the hacksaw and started. Boy that

graphite in cast iron sure makes it easy to cut. Made the cut in no time!!

Photo right shows in red about where I had to cut the cast iron starter

nose.

kit" that moved the starter from the left to right side so it would not

interfere with the steering. It was an

expensive purchase and when I received it I realized I had to cut off a part

of the starter nose to clear the housing. I recall pondering how I would

get this done. Probably kept me up one night! I put a new blade on the hacksaw and started. Boy that

graphite in cast iron sure makes it easy to cut. Made the cut in no time!!

Photo right shows in red about where I had to cut the cast iron starter

nose.

We raised the engine and pushed the car

under it. We lowered the engine, and lowered it and kept on lowering it!

Boy was it heavy. Thought I had raked the car. It was several inches lower

in the front than with the flathead! I also recall those motor mounts didn’t fit

the Ford rubber donuts holes very well.

I recall having to file the motor mount holes quite a bit to get the bolts onto the rubber donuts.

Finally it all fit.

The left side exhaust manifold was

hitting the steering column! The solution was to use another

right had manifold which I picked up at the junk yard. I remember

struggling getting the nuts off and the fellow who worked in the yard

to cut up parts put his cutting torch on the bolt and as I cringed he said, "Don’t worry it

won’t cut the cast iron." He proceeded to cut off the offending

bolt heads

and the manifold was unscathed.

Pop's body shop friend welded the exhaust pipe pieces I had fabricated by

slitting exhaust pipes and hammering them together to fit.

Time to start the engine! When I

assembled the hydraulic lifters

I had put a small amount of oil in each but as I cranked it over

none of the rockers moved. It took some time to get the pressure up and the

valves start to actuate. Put the valve covers on and hoped I had set the

distributor properly and the timing was good enough to at least start it

up. Even then it was known that you should run a new engine in for a ½ hour

or so. That I did and it ran fine! Set the timing with one of the

cheap dim

lights we had at the time. I recall another friend having built an engine

and he burned it out on his first run with no oil pressure. I loosened

the oil sender and saw oil squirt out! All seamed fine.

Had a local auto electrical wizard help get

the generator to work. He had to "polarized" it by shorting a terminal

to ground. Worked fine after that. However when the engine was

hot it cranked very slow. Fortunately a local company making

batteries, mostly for trucks, had what they called a 6-12 and 12-24 system.

The 6-12 was a two 6 volt batteries built into one case that had a solenoid

switch on top. It put the two batteries in series for starting and

then switched them with a big solenoid to a parallel connection. All accessories, lights

etc were connected to an "always 6 volt" location but it put 12 volts on the

starter making it made the engine spin the great. Just couldn’t run the starter too

long but with the increased starter speed the car started very quickly.

Had a local radiator shop block

off one of the inlet and outlets since the flathead had two of each. The car

would overheat and when I asked the radiator shop what they could do he had me

install a thermostat which I had elected not to use. As he explained;

"Your cavitating at the center of the water pump. Your boiling before

the radiator gets to 212 degrees!" He was right, it was a big help. No overheating except

at highway speeds. Went back and he made it a 15 psi pressure system. I

recall, he pressurized the radiator and found any leaky places and soldered

them. It worked. Used a 15 psi cap and let the temperature increase. For

all but sustained highway driving in the summer, which I did very little, it

was fine.

The car was really fast. However the skinny 16

inch diameter rear tires had little traction. When 1st gear

striped soon after the Olds was installed there was no problem. Taking off

in second could spin the tires until you backed off the gas! Also, to have

the gas peddle clear the higher Olds engine I had a piece brazed onto the

throttle shaft coming up at the firewall. It made the peddle have a

very short movement. Easy to get the wheels spinning. Drove the

car with two gears. The 4:11 rear and the torque of the Olds were more

than enough. One friend would bet, and mostly win, that he could beat a car on foot from telephone pole

to telephone pole from a standing start. I won that one easily. My buddy

with the '54 Pontiac sedan was very upset that I jumped several car lengths

on him in the quarter mile we had marked off on a newly built but little

used road and left him in the dust! We had installed 3 X

2's on his car, it was light and quick but not a match for the '41! Even beat a few

motorcycles! |

|

Clutch Bushing

One other anecdote is worth mentioning

since it was a learning experience I never forgot in my working career.

The clutch peddle linkage was sloppy and I found a very warn bushing at the

base shaft. The auto parts store did not carry the part. I asked

Pop what he thought and he suggested we go to a person he knew that worked

in the Ford Dealers parts department. He said this fellow had worked

in a junk yard and will know if something currently available would work. I recall

he and Pop were chatting and I asked the question; "Do you have a bushing

for the clutch shaft in the '41 Ford?" He said sarcastically; "What

does that sign say?" pointing to the sign above the counter. I said

"Ford Parts." He said "it doesn't say antique parts does it?"

I was mad! He went in the back and came back with a bushing and said "this will fit." I looked

at the spherical internal shape and said my bushing isn't spherical it won't work.

He took it back (or so I thought.) I drove home with Pop and was

talking about asking another uncle who was a machinist to make a bushing for

me. When we got home Pop pulled out of his pocket the part his friend

had showed me when I went in the car!! He said see if it fits! I

cleaned out all the extra grease I had put on the shaft, and wouldn't you

know - it was perfect! I had not seen the spherical shape on that part

of the shaft with all the extra grease I had pumped in with a grease gun!

What I learned from that experience was folks who work in an area are very

knowledgeable! Over the years I have learned far more from welders

that I have taught them! It may have been different information but

since I worked mostly with automatic submerged arc machine welders I always respected

what the operator knew about his machine and what settings worked! I

also learned the important of work grounds and their location. These

welders had learned that the "hard way!" |

|

Bottom Line

The car served me well and helped me get

into college studying engineering. I learned a lot and look back fondly at

my aggressive "can do attitude." We didn’t call them Rat Rods then but

compared to the guys buying ’57 fuelie Chevy’s, 406 Fords and Tri-power

Pontiacs right from the dealers, guess they were.

Download PDF of pictures of Rat

Rods at "The Run For

The

Sun" Car Show in Myrtle Beach SC. The

Sun" Car Show in Myrtle Beach SC.

Click

PDF ICON right or the Rat Rod Pic

on left.

CLICK TO See Video of "Rat

Rods Then and Now"

Includes Pictures of Rat Rods shown at

Myrtle Beach SC "Rub to the Sun" Car Show |

|

Purchase

Gas Saving Products Purchase

Gas Saving Products |

Purchase

Training Purchase

Training

Products |

Purchase

Flow Rate Limiter |

Purchase Wire Feeding Aids Purchase Wire Feeding Aids |

| |

Purchase Orifice Flow Control System |

|