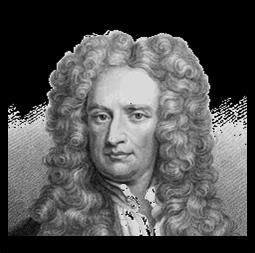

Daniel Bernoulli was born in 1700. He developed the understanding and

mathematical equations for defining the relationships between gas pressure,

temperature and volume. His equations form the basis of our understanding

of how airplanes fly and many other gases behavior phenomenon. For understanding and

quantifying the shielding gas waste problem, first review the material presented

in

Why Am I Using So Much

Shielding Gas?

Daniel Bernoulli was born in 1700. He developed the understanding and

mathematical equations for defining the relationships between gas pressure,

temperature and volume. His equations form the basis of our understanding

of how airplanes fly and many other gases behavior phenomenon. For understanding and

quantifying the shielding gas waste problem, first review the material presented

in

Why Am I Using So Much

Shielding Gas?

The higher pressure in the gas delivery hose when welding is

stopped versus when welding, creates an excess volume of shielding gas stored in

the hose. This excess gas is expelled when the torch switch is activated, even

if just inching the wire to cut off the end. It may occur in less than a

second although we have found it may take over 5 seconds to reduce to the preset

level in some installations. You can hear the gas surge, it is obvious.

Using the Bernoulli gas equations we can define the excess volume measured at

standard temperature and pressure as being proportional to the differences in

absolute hose pressure when stopped versus when welding.

Depending on the

regulator/flowmeter or gas pipeline pressure, the waste can exceed 5 times the

delivery hose volume every time the torch trigger is pulled.

WHY ARE GAS DELIVERY PRESSURES HIGH?

To provide automatic flow compensation for the inevitable

flow restrictions that occur in production, i.e. spatter build-up, twisted

cables etc is one key reason. They have been designed that way since

the introduction of TIG and MIG Welding!

See - - What is

Automatic Flow Compensation and Why it is Needed?