|

|

|

Submerged Arc Weld “Hard

Spots” Cause Cracking in "Sour Gas" Service |

|

OVERVIEW:

“Hard

Spots” in submerged arc welds have caused major weld failures. This

problem was identified in the early 1970’s when some weldments failed within

days of being exposed to H2S

(hydrogen sulfide.) This can occur in petrochemical processing and in

pipelines transporting "Sour Gas." “Hard

Spots” in submerged arc welds have caused major weld failures. This

problem was identified in the early 1970’s when some weldments failed within

days of being exposed to H2S

(hydrogen sulfide.) This can occur in petrochemical processing and in

pipelines transporting "Sour Gas."

Compared to the much smaller “Hard Spots”

recently reported as problems in welds made in HSLA steel, (Reference 1) the

“Hard Spots” encountered in the submerged arc

welds in question are much harder and much larger!

The above mentioned

article expressed concern that the hard areas in MIG

welds in HSLA steel that caused cracking problems in a H2S

test were about as big as the hardness tester indenter. As can be seen

in micrographs below, “Hard Spots” in a failed sub arc weld

made in large diameter transmission pipe were about 40 times the indenter size!

Those located at the surface are readily seen by eye! |

|

EARLY 1970’s

Harry Ebert, an Exxon Welding Engineer at

the time, published a paper in 1971 discussing hard welds caused by the use

of “active” bonded fluxes and subsequent rapid weld failures (Reference 2.)

We worked closely with Exxon, the API Vessel Committee and fabricators

defining which combination of fluxes and wires were to be used in the as

welded and stress relived condition for this service.

In 1973 a definitive 22 page technical paper

was published by Kotecki and Howden, working for Battelle Memorial

Institute, regarding submerged arc weld “Hard Spots”

(Reference 3.) It clearly showed failures similar to those discussed by

Ebert and defines the cause as “Hard Spots” in submerged arc welds made with

"active"

bonded fluxes, i.e. those containing Ferro Alloys. A majority of

bonded (also called agglomerated) fluxes contain Ferro Alloys for a

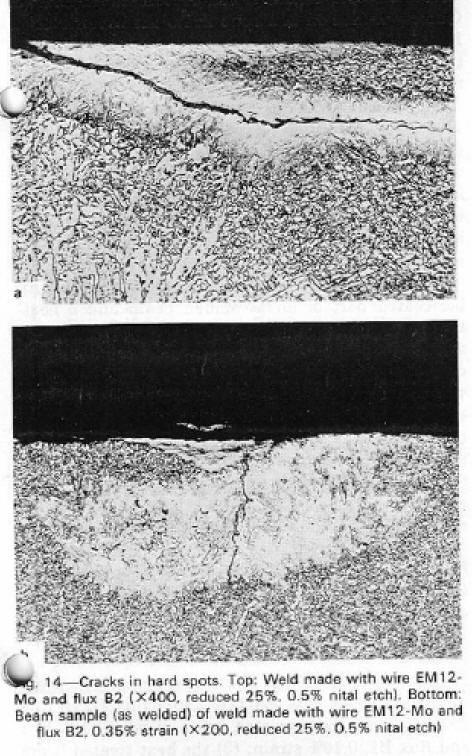

number of flux manufacture and weld performance reasons. The photo

macrograph directly below shows one

figure from the Kotecki/Howden report with cracked “Hard Spots.” They found relatively large, very high Mn and Si “Hard

Spots” in submerged arc welds made with bonded fluxes. These “Hard

Spots.” cracked rapidly when exposed to H2S testing.

|

|

1980’s

My early career was in research and

development of the submerged arc welding processes, fluxes and wires. I

presented

technical papers in a number of pipeline conferences on the subject of submerged arc welding

natural gas and oil transmission

pipe with a welding process we developed that welded long seams in UOE pipe at 3000 amps

(Summarized in Reference 4) that doubled

existing welding speeds. At these conferences, several papers addressed steels for use in sour

natural gas

service and the problems with hydrogen sulfide induced cracking. However none discussed possible weld metal problems when subjected

to sour gas.

With my experience with submerged arc weld

“Hard Spots” in pressure vessel failures, I discussed the issue

in visits with all North American pipemills. There were nine UOE

pipe mills in the US and Canada all of whom were using specially designed

high performance fused submerged arc fluxes made especially for this service.

Fused fluxes, as found by Kotecki/Howden did not produce

welds containing “Hard

Spots.”

[ Note: fused fluxes can be fully reacted during manufacture eliminating

the production of metal particles while welding. This compares to

bonded (also called agglomerated) fluxes whose ingredients are first reacted during welding.] At

that time, these UOE pipemills cleaned the steel surface prior to welding. Many used

automatic shot blasting of the complete pipe steel surface which helped with

subsequent corrosion coating as well as weld performance. A

Canadian spiral pipe mill was also manufacturing some natural gas and oil line pipe.

This spiral pipe mill also used fused flux specially designed for gas and

oil pipe production.

Visiting most of the US and Canada UOE natural gas and oil pipemills

several times per year, they were verbally told about the concerns of using

active bonded fluxes for the manufacture of gas and oil pipe that could be used for

transporting sour gas. A spiral pipemill

making some gas and oil transmission pipe decided to use an active bonded

flux apparently to handle the extra mill scale on their plate. They produced pipe for a natural gas

transmission line that was placed

in the Grizzly Valley in Canada. It operated satisfactorily for a period of

time until a gathering line from a gas field containing sour gas was added.

Sections of the

line failed catastrophically within a very short time of being put in sour

gas service. The failure occurred in very long lengths at several

locations!

Little is

written about this major failure for some legal reasons.

However in a

Corrosion Conference held in San Francisco on March 9-13, 1987, a technical

paper was presented and proceedings published (Reference 5.) One of their conclusions

states; "Analysis of failures revealed they (cracks) originated in the inside weld

bead of a spiral weld which contained hard areas of Martensite and/or Banite

with hardness values between 300 and 500 HV." They go on to say pipe

used in this gas line made at another pipe mill (My

Note: no doubt a UOE mill using fused flux, since only this one spiral pipemill was making large diameter gas pipe at that time and all UOE pipemills in North America were utilizing fused flux,)

had no such

“Hard

Spots”

and that pipe, transporting the same sour gas, did not fail.

|

| LATE 1999 thru 2000’s

In 1999, with most of the natural gas and oil pipeline

infrastructure in place in the United States, there was only one UOE US pipemill approved for

API gas and oil pipe production (now that pipemill is also closed and dismantled.)

That mill stopped

using their plate surface shot blaster because of high maintenance cost.

Therefore the fused submerged arc flux they had been using was replaced with a bonded flux

to handle the plate mill scale. [Note, bonded

fluxes contain deoxidizers such as Ferromanganese and Ferrosilicon.

These Ferro Alloys combine with iron oxide and prevent CO weld

porosity from forming. However they also produce Mn and Si rich hard

spots!] The flux manufacturer designated this grade as

being designed for pipe manufacture welding. It was an active bonded

flux. We were asked to examine a failed weld made with this flux

causing the pipe to burst open during hydro testing. The pipe had failed

along the full 40 foot weld seam. We observed several large sections with the

crack moving along the weld and in and out of the weld and HAZ. The pipe

mill metallurgist found no issues with the steel different than the

remaining steel used for all of the pipes being produced for the pipe order.

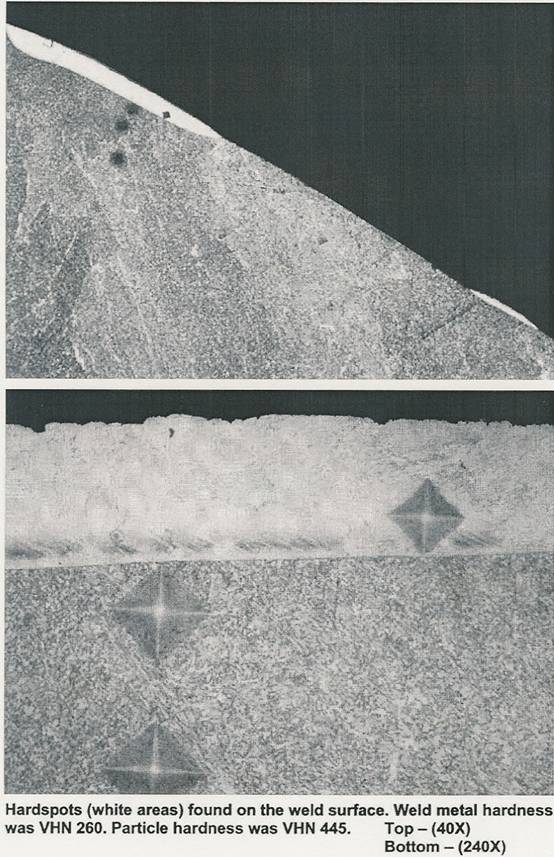

A detailed examination of a small section of

pipe weld we were given showed many “Hard Spots”

on

the surface (about 20 per inch.) An EDAX trace showed them to be very high

in Mn and Si. The hardness of these obviously martensitic areas was 445 VHN.

As seen in the photomicrographs below they were very large, 3 or 4 times

larger than those observed by Kotecki/Howden (Reference 3.)

|

| HARD SPOT TEST DEFINED

A test for submerged arc weld “Hard

Spots” was developed for a major oil company. They will use

it in specifications for pipe exposed in Sour Gas Service. The test is

simple and involves making a weld pad.

Note About Required

Sour Gas Corrosion Tests: Some of the corrosion test samples

required for pipe used for sour gas service require the weld bead be ground flush

with the plate surface. This can eliminated the offending surface

"Hard Spot!" It is suggested some corrosion tests be made with the

weld reinforcement in place as this is the way the pipe will be used in

service!

|

| BOTTOM LINE

Having extensive experience related to the use

of submerged arc welding in the manufacture of natural gas and oil transmission pipe, as well as research experience

and patents for fluxes and wires used for submerged arc welding pipe, I am in a

unique position to define why these “Hard Spots”

exist. I can discuss issues such as flux raw ingredients, raw material sizing, mixing

etc that determine their size and frequency. I can help define

appropriate tests for these “Hard Spots.”

Other welding processes

and consumables could possibly cause similar issues.

Email to discuss

consulting on the subject. |

|

REFERENCES:

-

“Effect

of Welding Parameters and H2S

Partial Pressure on the Susceptibility of Welded HSLA Steels to Sulfide

Stress Cracking; “by G.M. Omweg, G.S. Frankel, W.A. Bruce, J.E. Ramirez

and G. Koch; AWS Welding Journal, June 2003

-

“Hard Welds -Their Causes and

Prevention,” H. W. Ebert, AWS Welding Journal, September 1971

-

“Submerged

Arc Weld Hardness and Cracking in Wet Sulfide Service,” by D. J.

Kotecki and D. G. Howden, WRC (Welding Research Council) Bulletin Number No.184 (1973)

-

"Three Wire

Submerged Arc Welding of Line Pipe," by G. D. Uttrachi and J. E. Messina,

AWS Welding Journal, June 1968

-

“Pipeline

Failures in the Grizzly Valley Sour Gas Pipeline,” by V. B. Lawson, C.

Duncan, R. S. Treseder; CORROSION/87, paper no. 52, (Houston TX; NACE,

1987)

|

|